Paste adhesive composition and semiconductor device

An adhesive and composition technology, which is used in the manufacture of semiconductor devices, conductors, and semiconductor/solid-state devices, etc., can solve the problem of weak adhesion, inability to fully obtain the adhesion between the metal particle connecting structure and the adherend, and peeling off. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

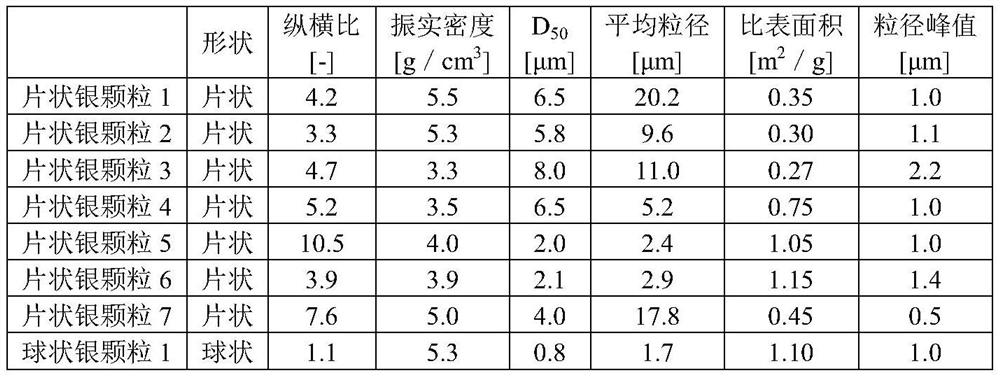

[0209] Hereinafter, the present invention will be described in detail by using examples, but the present invention is not limited at all by the description of these examples.

[0210]

[0211] First, the raw material components used in Examples and Comparative Examples will be described in detail.

[0212] (monomer)

[0213] The following monomers were used as monomers.

[0214] ·Diol monomer 1: Tripropylene glycol mono-n-butyl ether (manufactured by Japan Emulsifier Company, BFTG, boiling point at atmospheric pressure (101.3kPa) is 274°C)

[0215] ·Diol monomer 2: ethylene glycol mono-n-butyl acetate (manufactured by Tokyo Chemical Industry Co., Ltd., BCSA, boiling point at atmospheric pressure (101.3kPa) is 192°C)

[0216] ·Monofunctional acrylic monomer 1: 2-phenoxyethyl methacrylate (manufactured by Kyoeisha Chemical Co., Ltd., PO)

[0217] ·Monofunctional acrylic monomer 2: 1,4-cyclohexanedimethanol monoacrylate (manufactured by Nippon Kasei Kogyo Co., Ltd., CHDMMA)

[0218] ·Multifun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com