Mounting and welding method for controlling tracking errors of coaxial optical devices

A technology of tracking error and welding method, which is applied in the field of optical communication, can solve the problems of increased scrap rate, tracking error of coaxial optical devices, and reduced scrap rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

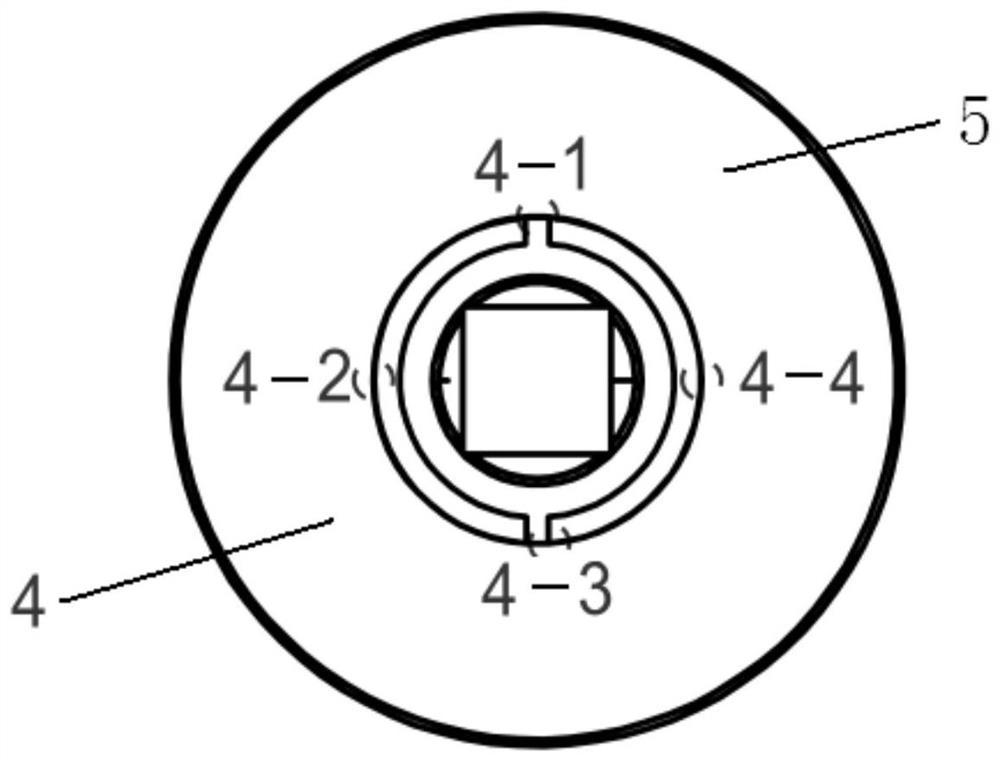

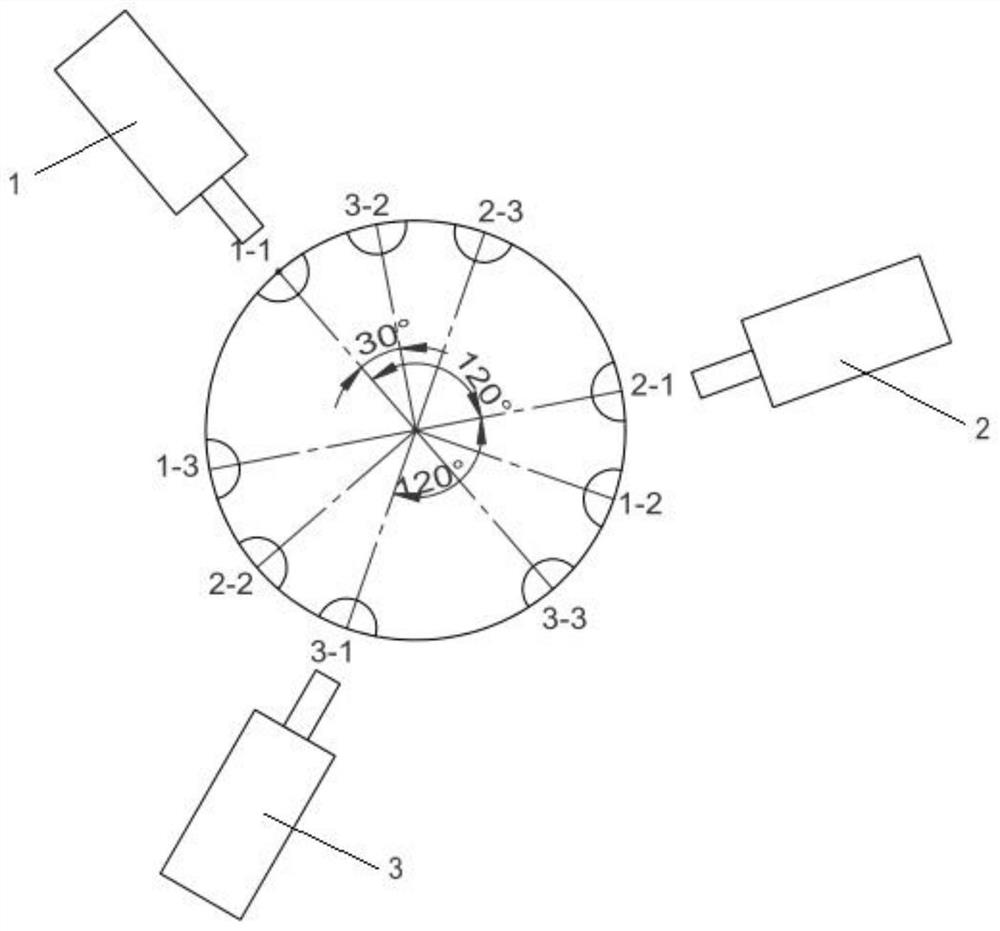

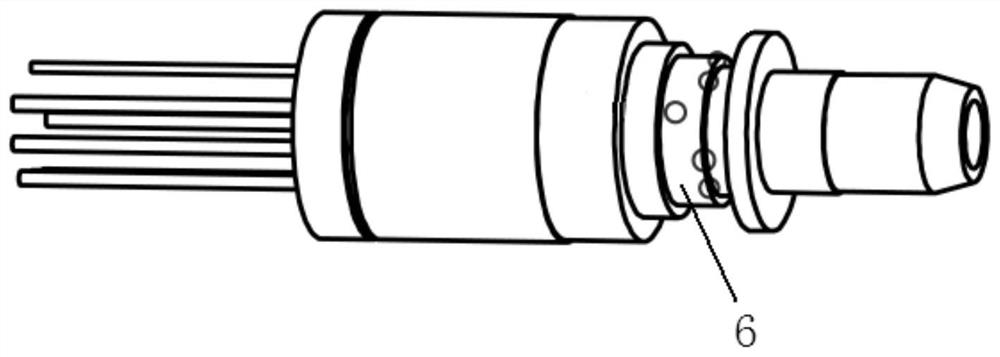

[0028] The present invention will be described in detail below with reference to the drawings and embodiments, but the present invention is not limited to specific embodiments.

[0029] A mounting and welding method for controlling tracking errors of coaxial optical devices, including the following steps:

[0030] (1) Mounting of optical components: use gold-tin solder Sn / Au:80 / 20 to mount the chip on the heat sink, the thickness of the gold-tin solder is controlled between 3-6 microns, the solder is uniform, and the silver glue 84- 1 Mount the 45-degree all-reflection film on the plane optical path, the thickness of the silver glue is controlled between 3-6 microns, the glue is uniform, and the force direction is uniform, so that the thermal expansion coefficient of the optical path will remain the same without making the optical path Offset, after the laser chip emits light, the 45-degree all-reflection film rotates the light path by 45 degrees, and the vertical base is upward;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Penetration | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com