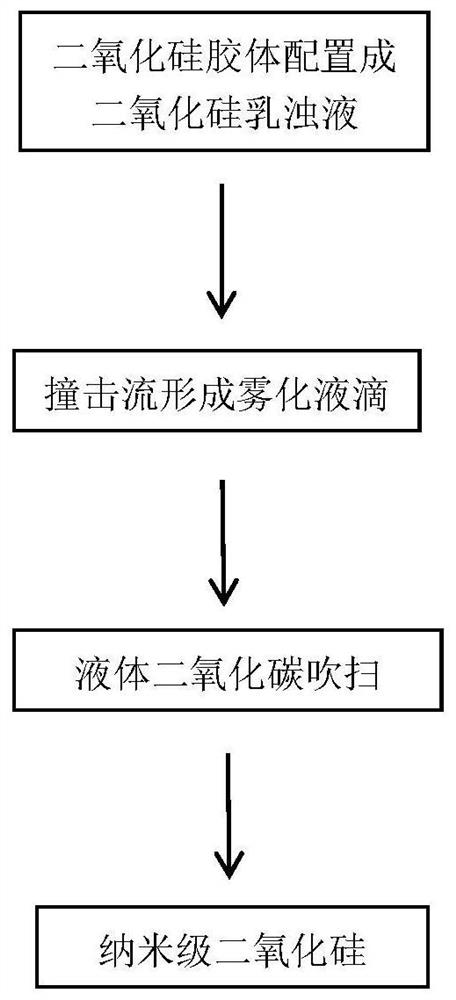

Method for preparing nano silicon dioxide by impinging stream

A technology of nano-silicon dioxide and silicon dioxide, which is applied in the fields of silicon dioxide, silicon oxide, nanotechnology, etc., can solve the problems such as the inability to prepare nano-scale silicon dioxide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

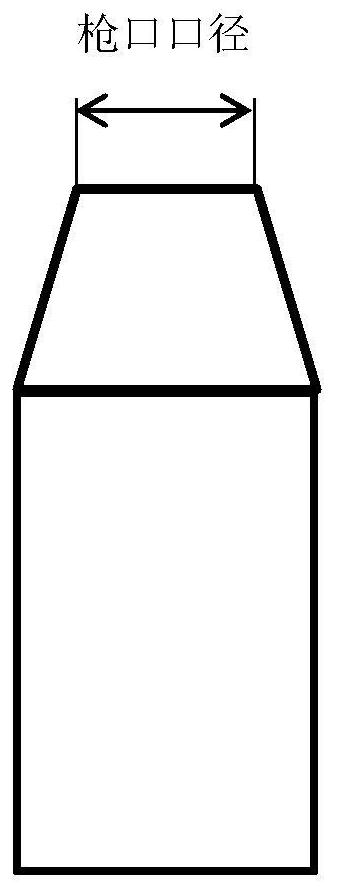

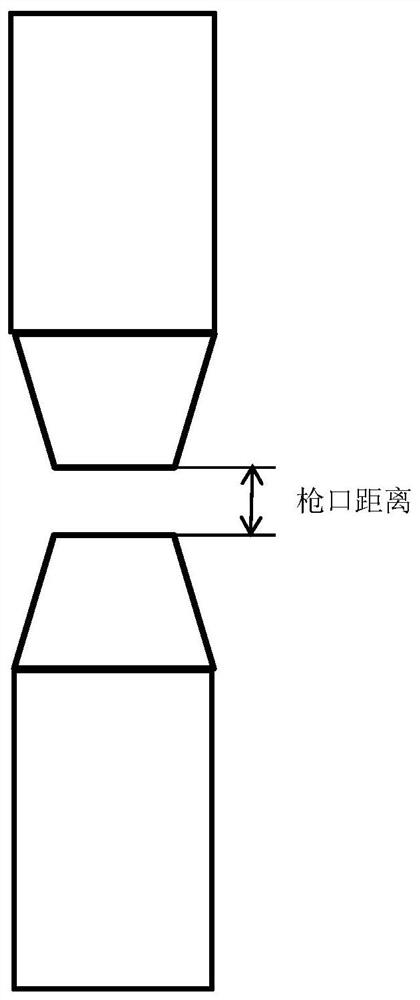

[0037]Add water to silica colloid with a conductivity of 1 us / cm to form a 3% silica emulsion, and stir evenly. Transfer the evenly stirred silica emulsion to the high-pressure jet device with two high-pressure gun heads, control the injection pressure at 1MPa, the distance between the gun tips is 1mm, and the diameter is 2mm. Turn on the gun head switch, and shoot two strands of silica emulsion. Due to the existence of the rifling of the gun head, the jet is ejected in a spiral shape and the impulse is increased. After the two spiral jets collide, energy conversion occurs, and the two liquids radiate outward in the form of turbulent flow to form atomized nano-droplets. At the same time, the liquid carbon dioxide is turned on to purge and atomize the nano-droplets. The temperature of the liquid carbon dioxide is -40°C, and the purge pressure is 1MPa, so that the formed nano-droplets are rapidly solidified, and the solidified nano-silica products are collected and heated under ...

Embodiment 2

[0039] Add water to colloidal silicon dioxide with a conductivity of 5 us / cm to form a 10% silicon dioxide emulsion, and stir evenly. Transfer the uniformly stirred silica emulsion to the high-pressure jet device with two high-pressure gun heads, control the injection pressure to 3MPa, the distance between the gun tips to 2mm, and the caliber to 1mm. Turn on the gun head switch, and shoot two strands of silica emulsion. Due to the existence of the rifling of the gun head, the jet is ejected in a spiral shape and the impulse is increased. After the two spiral jets collide, energy conversion occurs, and the two liquids radiate outward in the form of turbulent flow to form atomized nano-droplets. At the same time, the liquid carbon dioxide is turned on to purge and atomize the nano-droplets. The temperature of the liquid carbon dioxide is -50°C, and the purge pressure is 2MPa, so that the formed nano-droplets are quickly solidified, and the solidified nano-silica products are col...

Embodiment 3

[0041] Add water to silica colloid with a conductivity of 5 us / cm to form a 15% silica emulsion, and stir evenly. Transfer the uniformly stirred silica emulsion to the high-pressure jet device with two high-pressure gun heads, control the injection pressure to 5MPa, the distance between the gun heads to 2mm, and the diameter to 1.5mm. Turn on the gun head switch, and shoot two strands of silica emulsion. Due to the existence of the rifling of the gun head, the jet is ejected in a spiral shape and the impulse is increased. After the two spiral jets collide, energy conversion occurs, and the two liquids radiate outward in the form of turbulent flow to form atomized nano-droplets. At the same time, the liquid carbon dioxide is turned on to purge and atomize the nano-droplets. The temperature of the liquid carbon dioxide is -40°C, and the purge pressure is 3MPa, so that the formed nano-droplets are quickly solidified, and the solidified nano-silica products are collected and heate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com