Preparation method of low-oil-absorption nano silicon dioxide for high-elasticity silicone rubber

A nano-silica, silicone rubber technology, applied in the direction of silica, aluminum hydroxide preparation, silicon oxide, etc., can solve the problem of low rebound rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

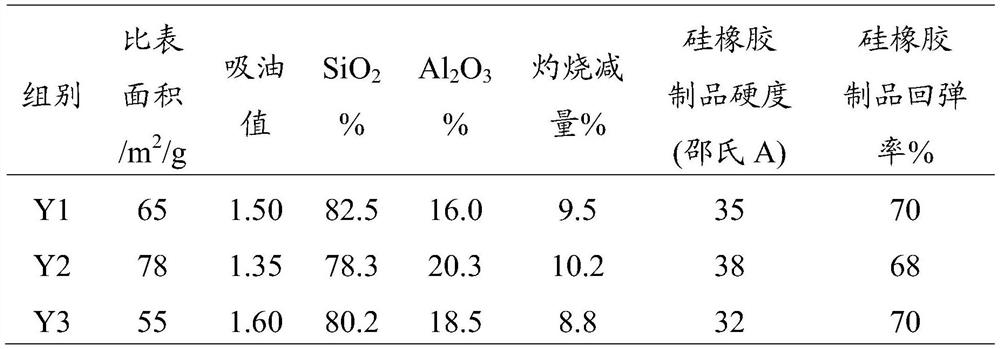

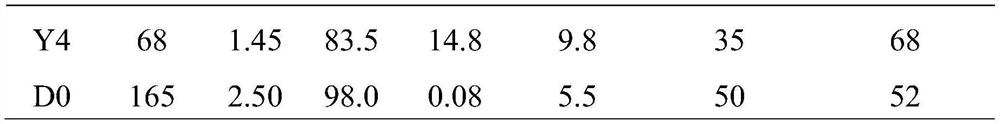

Examples

preparation example Construction

[0014] The invention provides a method for preparing nano-silica for high-elasticity silicone rubber, comprising the following steps:

[0015] After the bottom water is warmed up, add 1-5wt% solid sodium sulfate in the bottom water and stir to dissolve, then add water glass solution accounting for 30-50% of the bottom water volume and stir evenly to obtain a reaction solution, respectively control the flow rate to 3-6m 3 / h and 10-15m 3 / h add dilute sulfuric acid and water glass solution, the continuous addition time is 100-135min, then add acidic aluminum sulfate solution to adjust the pH value of the reaction solution to 3-5 to obtain a reaction slurry;

[0016] Wherein the concentration of aluminum sulfate in the acidic aluminum sulfate solution is 14.3-38.0wt%, the SiO of the water glass solution 2 The content of is 15-25wt%;

[0017] The reaction slurry is washed with water, then dried and pulverized to obtain nano silicon dioxide for high elastic silicone rubber.

[...

Embodiment 1

[0031] at 10m 3 Add 2m to the enamel reactor 3 water, add 2m 3 30wt% dilute sulfuric acid, start stirring and then add 572kg solid aluminum sulfate, stir for 30min to prepare acidic aluminum sulfate solution. Select high-quality food-grade solid water glass with a modulus of 3.3, put it into a static autoclave, add treated water, introduce steam through a precision filter, pressurize to 0.6MPa, keep the pressure for 2 hours, add water, and prepare SiO 2 Content is the water glass solution of 22wt%, store for future use.

[0032] at 60m 3 First add 10m 3 The bottom water is heated to 90°C by steaming, adding 500kg of solid sodium sulfate and stirring to dissolve, then adding 3m 3 The water glass solution is stirred evenly to obtain the reaction solution, and the reaction starts, and the flow rate is controlled at 5m 3 / h and 15m 3 Add 18wt% dilute sulfuric acid and the water glass solution per h, the continuous addition time is 120min, the pH value of the control reactio...

Embodiment 2

[0034] at 10m 3 Add 2m to the enamel reactor 3 water, add 1m 3 30wt% dilute sulfuric acid, start stirring and then add 600kg solid aluminum sulfate, stir for 30min to prepare acidic aluminum sulfate solution. Select high-quality food-grade solid water glass with a modulus of 3.5, put it into a static autoclave, add treated water, introduce steam through a precision filter, pressurize to 0.8MPa, keep the pressure for 3 hours, add water, and prepare SiO 2 Content is the water glass solution of 25wt%, store for future use.

[0035] at 60m 3 First add 10m 3 The bottom water is heated to 92°C by steaming, adding 300kg of solid sodium sulfate and stirring to dissolve, then adding 4m3 The water glass solution is stirred evenly to obtain the reaction solution, and the reaction starts, respectively controlling the flow rate of 4m 3 / h and 12m 3 / h adds 22wt% dilute sulfuric acid and the water glass solution, the continuous addition time is 115min, the pH value of the control reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com