A kind of treatment method of cyanidation gold extraction wastewater

A treatment method and wastewater technology, applied in the field of resource utilization of hazardous waste, can solve the problems of excessive heavy metals and cyanide in wastewater, large consumption of oxidants, serious equipment corrosion, etc., achieve high removal rate of heavy metals, simple wastewater treatment process, The effect of a wide range of raw material sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

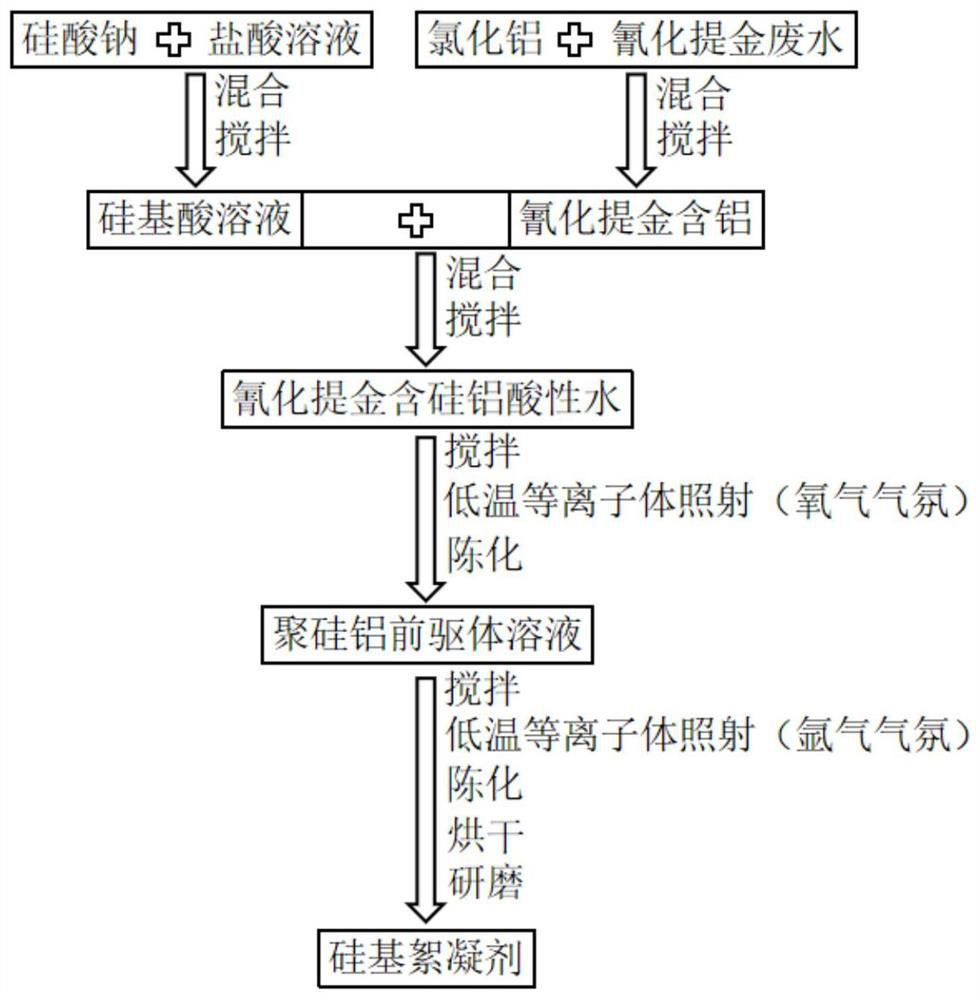

Method used

Image

Examples

Embodiment 1

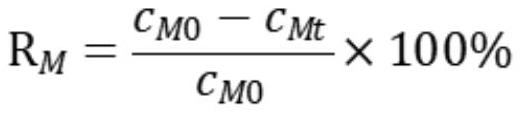

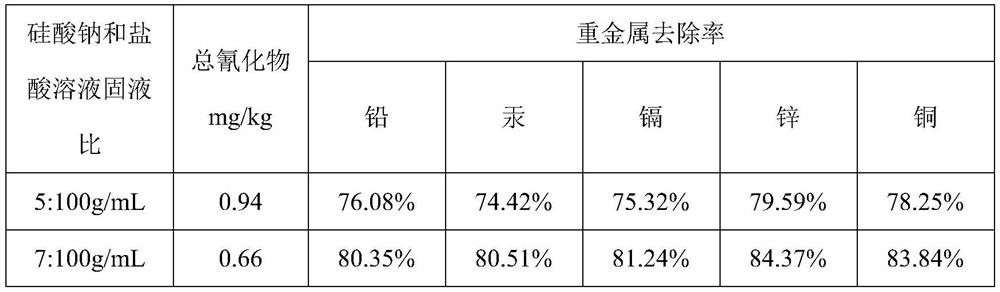

[0020] Example 1 Effect of solid-to-liquid ratio of sodium silicate and hydrochloric acid solution on the performance of the prepared flocculant

[0021] According to the solid-to-liquid ratio of sodium silicate and hydrochloric acid solution 5:100g / mL, 7:100g / mL, 9:100g / mL, 10:100g / mL, 20:100g / mL, 30:100g / mL, 32:100g / mL Weigh sodium silicate and hydrochloric acid solution at mL, 35g / mL, and 40:100g / mL respectively, mix and stir until the sodium silicate is completely dissolved to obtain a silicon-based acid solution, wherein the mass fraction of hydrochloric acid in the hydrochloric acid solution is 10%. According to the solid-liquid ratio of aluminum chloride and cyanide gold extraction wastewater of 5:100g / mL, aluminum chloride and cyanide gold extraction wastewater were weighed, mixed, and stirred until the aluminum chloride was completely dissolved to obtain cyanide gold extraction aluminum-containing wastewater. Measure the silicon-based acid solution and the aluminum-co...

Embodiment 2

[0030] Example 2 Effect of solid-liquid ratio of aluminum chloride and cyanidation gold extraction wastewater on the performance of the prepared flocculant

[0031] Take sodium silicate and hydrochloric acid solution respectively according to the solid-to-liquid ratio of sodium silicate and hydrochloric acid solution 30:100g / mL, mix, stir until sodium silicate dissolves completely, obtain silicic acid solution, wherein the mass fraction of hydrochloric acid in the hydrochloric acid solution is 20%. According to the solid-liquid ratio of aluminum chloride and cyanide gold extraction wastewater 2.5:100g / mL, 3.5:100g / mL, 4.5:100g / mL, 5:100g / mL, 10:100g / mL, 15:100g / mL, 15.5 : 100g / mL, 16.5: 100g / mL, 17.5: 100g / mL respectively weigh aluminum chloride and cyanide gold extraction wastewater, mix, stir until aluminum chloride is completely dissolved, and obtain cyanide gold extraction aluminum-containing wastewater. Measure the silicon-based acid solution and the aluminum-containing ...

Embodiment 3

[0036] Example 3 Effect of the volume ratio of silicon-based acid solution and aluminum-containing wastewater from cyanidation gold extraction on the performance of the prepared flocculant

[0037] Take sodium silicate and hydrochloric acid solution respectively according to the solid-to-liquid ratio of sodium silicate and hydrochloric acid solution 30:100g / mL, mix, stir until sodium silicate dissolves completely, obtain silicic acid solution, wherein the mass fraction of hydrochloric acid in the hydrochloric acid solution is 30%. According to the solid-liquid ratio of aluminum chloride and cyanide gold extraction wastewater of 15:100g / mL, aluminum chloride and cyanide gold extraction wastewater were weighed, mixed, and stirred until the aluminum chloride was completely dissolved to obtain cyanide gold extraction aluminum-containing wastewater. According to the volume ratio of silicon-based acid solution and cyanidation gold extraction aluminum-containing wastewater 0.25:1, 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com