Method for extracting and purifying cannabidiol in cannabis sativa

A cannabidiol and cannabis technology, which is applied in the field of extracting and purifying cannabidiol, can solve the problems of low purity of cannabidiol, large investment, and difficulty in completely removing tetrahydrocannabinol.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

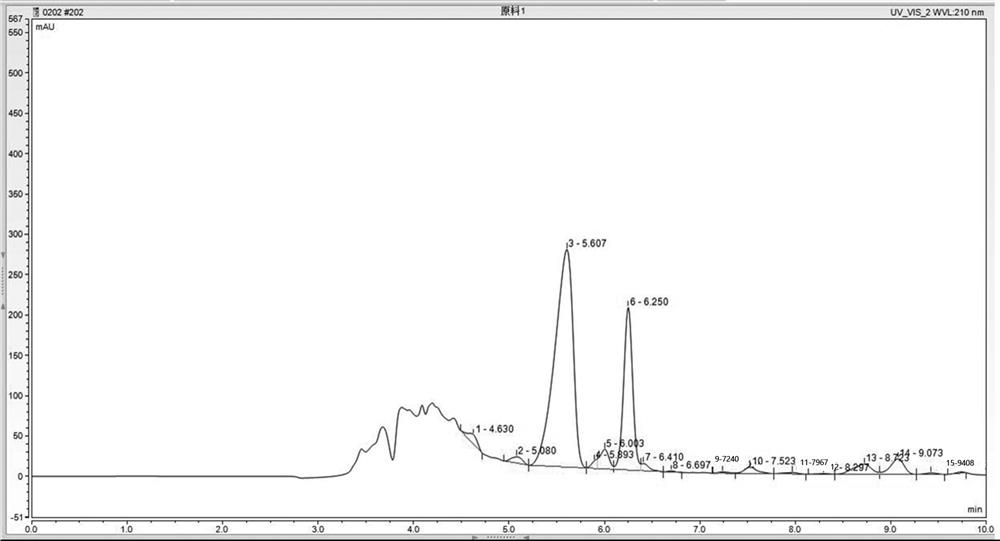

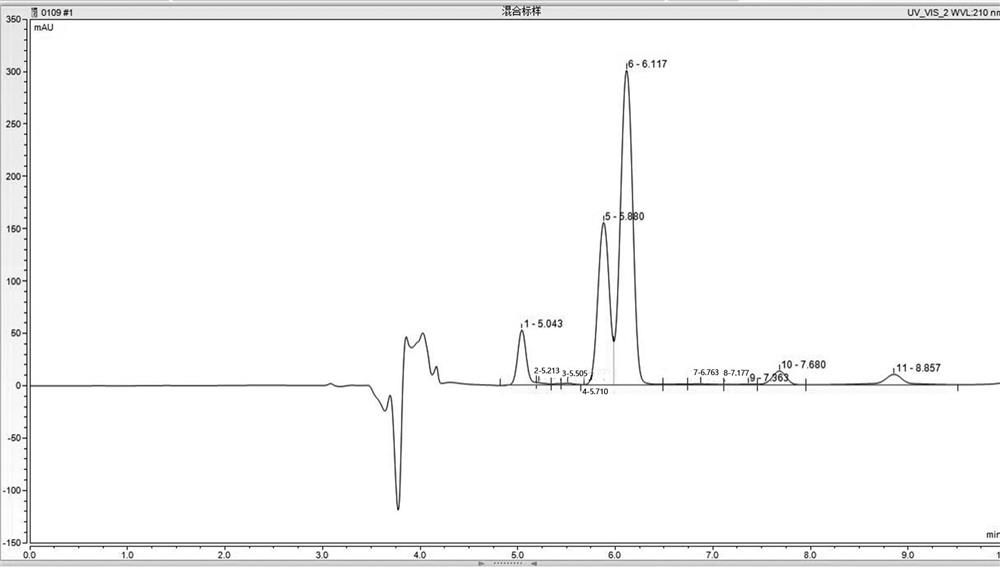

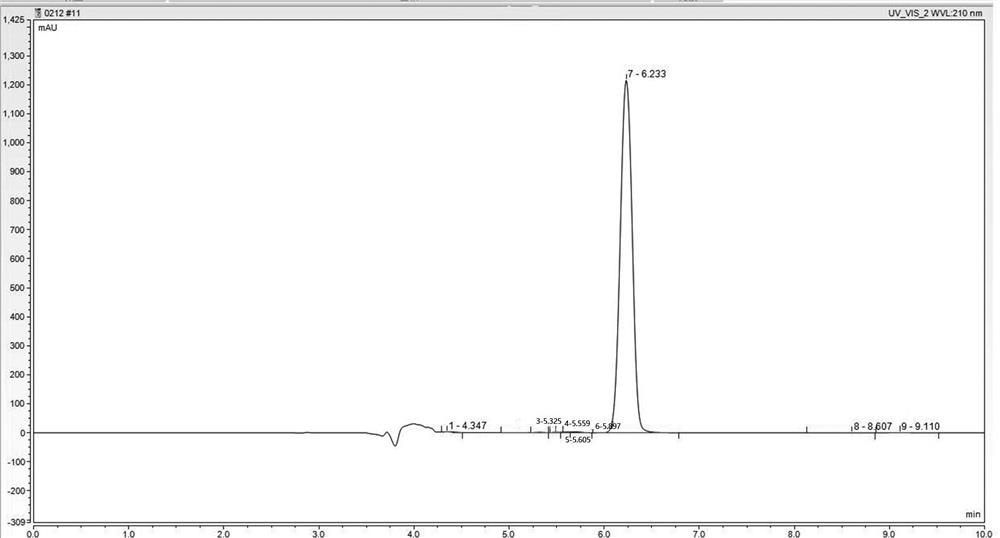

Image

Examples

Embodiment 1

[0051] The marijuana leaves and flowers are harvested, dried at a temperature of 80°C until the water content is 5%, and the materials are crushed to 60 mesh to obtain clean materials for use.

[0052] Weigh 60kg of clean material, and feed it continuously into the continuous countercurrent extraction equipment (model ND50-1000) according to the feed rate of 15kg / h. The solvent is extracted with ethanol solution to obtain a crude extract, in which the ethanol solution is continuously extracted at a rate of 60L / h Feed, the concentration of ethanol solution is 95%, the feed ratio of ethanol solution to clean material is 4, the extraction temperature is 40°C, and the extraction time is 60 minutes.

[0053] The obtained crude extract is concentrated in a vacuum low-temperature concentrator at a concentration temperature of 50°C to a solid content of 15%, and then frozen and winterized to remove impurities. The winterization temperature is -65°C and the winterization time is 8 hours...

Embodiment 2

[0061] The marijuana leaves and flowers are harvested, dried at a temperature of 150°C to a water content of 3%, and the materials are crushed to 20 meshes to obtain clean materials for use.

[0062] Weigh 60kg of clean material, and feed it continuously into the continuous countercurrent extraction equipment (model ND50-1000) at a feed rate of 15kg / h. The solvent is extracted with ethanol solution to obtain a crude extract. The ethanol solution is continuously extracted at a rate of 90L / h. Feed, the concentration of ethanol solution is 60%, the feed ratio of ethanol solution to clean material is 6, the extraction temperature is 20°C, and the extraction time is 120 minutes.

[0063] The obtained crude extract is concentrated in a vacuum low-temperature concentrator at a concentration temperature of 70°C to a solid content of 10%, then frozen and winterized to remove impurities. The winterization temperature is -20°C and the winterization time is 20 hours. During the freezing pr...

Embodiment 3

[0070] The marijuana leaves and flowers are harvested, dried at a temperature of 100°C to a water content of 1%, and the materials are crushed to 80 meshes to obtain clean materials for use.

[0071] Weigh 60kg of clean material, and feed it continuously into the continuous countercurrent extraction equipment (model ND50-1000) according to the feed rate of 15kg / h. The solvent is extracted with ethanol solution to obtain a crude extract, in which the ethanol solution is continuously Feed, the concentration of ethanol solution is 90%, the feed ratio of ethanol solution to clean material is 20, the extraction temperature is 30°C, and the extraction time is 30 minutes.

[0072] The obtained crude extract is concentrated in a vacuum low-temperature concentrator at a concentration temperature of 60°C to a solid content of 15%, then frozen and winterized to remove impurities. The winterization temperature is -80°C and the winterization time is 5 hours. During the freezing process, imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com