Digital printing process of cellulosic fiber fabric

A cellulose fiber, digital printing technology, applied in dyeing, textile and papermaking, etc., can solve problems such as increasing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

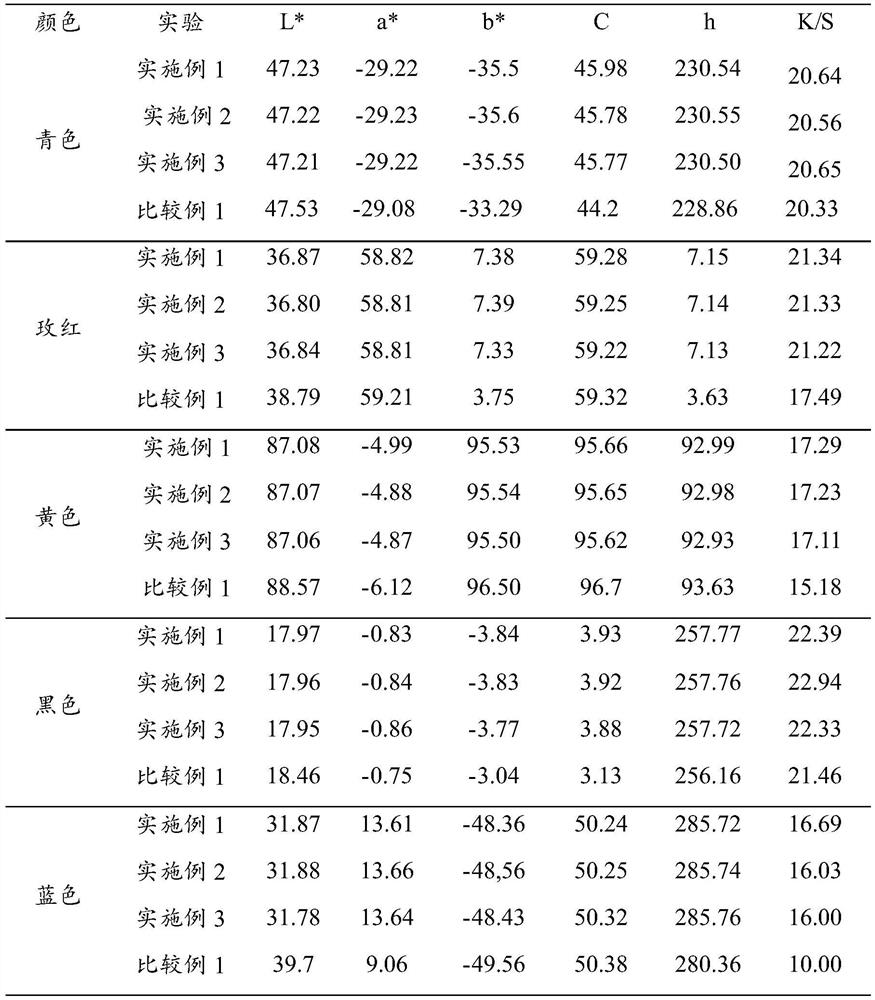

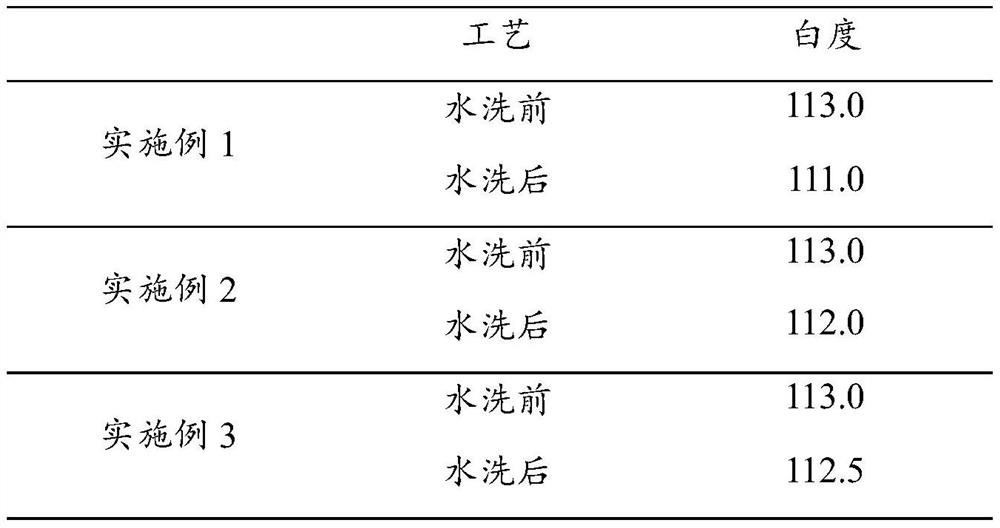

Examples

Embodiment 1

[0062]Prepare modifier 3-chloro-2-hydroxypropyltrimethylammonium chloride solution 120g / L and sodium hydroxide solution 20g / L volume ratio 1:1 and mix evenly, then pad pure cotton fabric fabric, fabric specification 40×40, 133×72, one dipping and one rolling, the liquid retention rate is 75%. After drying at 100°C, bake at 120°C for 1.5min. Next, wash with water at room temperature, wash with hot water at 95-98°C twice, wash with water at room temperature, wash with 2 g / L citric acid solution to neutralize water, wash with water at room temperature, and dry at 100°C.

[0063] The digital printing is normally printed, and after drying at 100°C, the fabric is steamed in a steam box at a steaming temperature of 100-103°C and a steaming time of 10 minutes.

[0064] Prepare 80g / L aqueous solution of sodium polysulfonylstyrene, pad and pad the steamed fabric with a liquid retention rate of 75%, and then dry it at 100°C.

Embodiment 2

[0066] Prepare modifier epoxy propyl trimethyl ammonium chloride aqueous solution 60g / L, sodium hydroxide aqueous solution 10g / L, mix evenly at a volume ratio of 1:1, then pad and pad pure cotton fabric fabric, fabric specification 40×40, 133 ×72, one soaking and one rolling, the liquid retention rate is 76%, and it is stacked at room temperature for 24 hours. Next, wash with water at room temperature, wash with hot water at 95-98°C twice, wash with water at room temperature, neutralize and wash with 2g / L citric acid solution until nearly neutral, wash with water at room temperature, and dry at 100°C.

[0067] Digital printing is normally spray printed, dried at 100°C, and the fabric is steamed in a steam box at a steaming temperature of 100-103°C and a steaming time of 10 minutes.

[0068] Prepare 80g / L aqueous solution of sodium polysulfonylstyrene, pad the steamed fabric with 75% liquid, and then dry it at 100°C.

Embodiment 3

[0070] Prepare modifier 3-acrylamide-2-hydroxypropyltrimethylammonium chloride 80g / L, sodium hydroxide aqueous solution 10g / L volume ratio 1:1 and mix evenly, then pad pure cotton fabric fabric, fabric specification 40 ×40, 133×72, one soaking and one rolling, the liquid retention rate is 76%, and it is stacked at room temperature for 24 hours. Next, wash with water at room temperature, wash with hot water at 95-98°C twice, wash with water at room temperature, neutralize and wash with 2g / L citric acid solution until nearly neutral, wash with water at room temperature, and dry at 100°C.

[0071] Digital printing is normally spray printed, dried at 100°C, and the fabric is steamed in a steam box at a steaming temperature of 100-103°C and a steaming time of 10 minutes.

[0072] Prepare 80g / L 2-naphthalenesulfonic acid formaldehyde polymer sodium salt aqueous solution, pad the steamed fabric with 75% of the liquid, then dry at 100°C

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com