Self-assembly growth method of array heterojunction

A heterojunction, self-assembly technology that can be used in sustainable manufacturing/processing, electrical components, climate sustainability, etc., and can solve problems such as poor controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

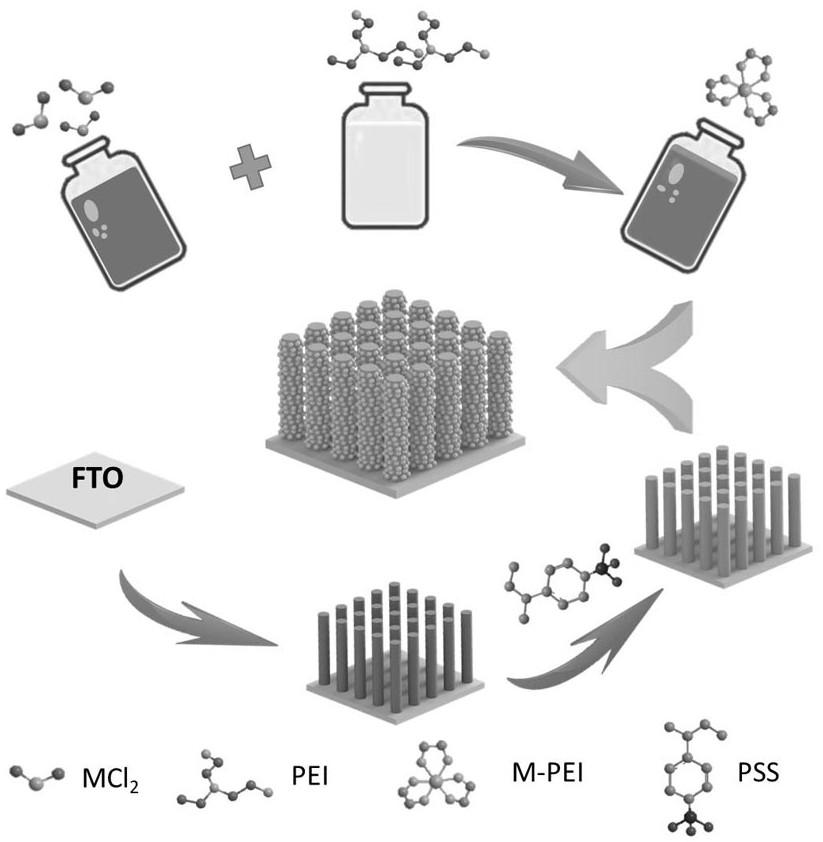

[0026] Implementation routes such as figure 1 As shown, the specific steps are as follows:

[0027] a. Take a certain amount of PSS (average molecular weight 70,000) powder and add it to the ethanol solution, prepare a PSS solution with a mass concentration of 5%, and stir it well at room temperature to make it uniform.

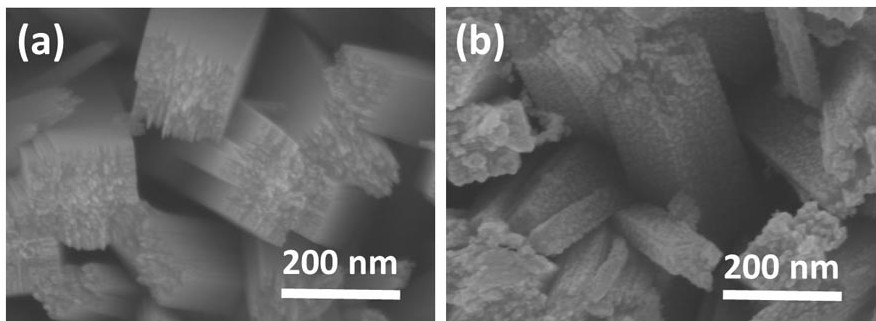

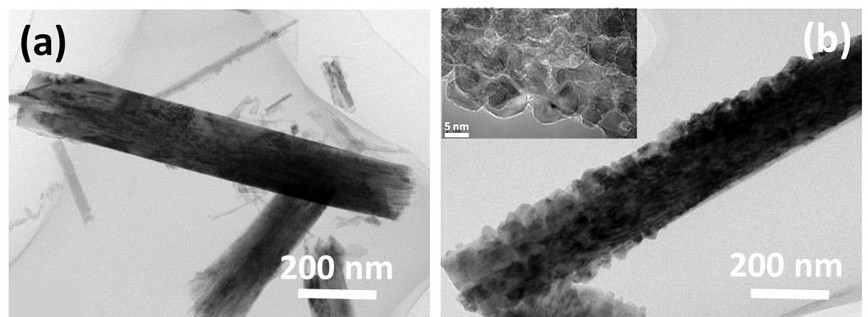

[0028] b. Titanium dioxide array column grown by hydrothermal method (see Energy Environ. Sci., 2016,9, 2633) (eg figure 2 (a) and image 3 The morphology shown in (a)) was soaked in the above PSS solution, placed on a flat heater and heated at 90°C for 2 hours, and then naturally cooled to room temperature and dried to form a PSS-modified array substrate.

[0029] c. Add nickel chloride to an aqueous solution containing PEI (branched polyethyleneimine, with an average molecular weight of 10 000) (the mass fraction of PEI is 20%-40%) and stir to make it fully react, PEI and metal ions pass through the complex A stable coordination compound is formed in a ...

Embodiment 2

[0033] a. Clean and dry the titanium dioxide array column grown by hydrothermal method (see Energy Environ. Sci., 2016, 9, 2633) and dry it for use.

[0034] b. Add nickel chloride to an aqueous solution containing PEI (branched polyethyleneimine, average molecular weight 10 000) (the mass fraction of PEI is 20%-40%) and stir to make it fully react, PEI and metal ions pass through the complex A stable coordination compound is formed in a combined way, and after a full reaction, the solution passes through an ultrafiltration device (if the molecular weight is greater than the molecular weight of the filter membrane, it cannot pass through the filter membrane, and if the molecular weight is smaller than the molecular weight of the filter membrane, it can be filtered out) There will be no complexed The nickel ions are filtered out to form the final precursor solution of nickel. The final precursor solution is uniform and stable at the molecular level. The viscosity and concentrati...

Embodiment 3

[0038] The specific steps are as follows:

[0039] a. Take a certain amount of PSS (average molecular weight: 70,000) powder and add it to the ethanol solution, configure a PSS solution with a mass fraction of 5%, and fully stir it at room temperature to make it uniform;

[0040] b. Soak the titanium dioxide array column grown by the hydrothermal method (see Energy Environ. Sci., 2016, 9, 2633) in the above PSS solution, place it on a flat heater and heat it at 90°C for 2 hours, and then cool down naturally to Dry at room temperature to form a PSS-modified array substrate;

[0041] c. Add zinc nitrate to an aqueous solution containing PEI (branched polyethyleneimine, average molecular weight 10 000) (the mass fraction of PEI is 20%-40%) and stir to make it fully react. The filter device (if the molecular weight is greater than the molecular weight of the filter membrane, it cannot pass through the filter membrane, and if the molecular weight is smaller than the molecular weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com