Bio-based epoxy resin containing triazine ring structure and preparation method thereof

A technology based on epoxy resin and triazine ring, which is applied in the field of bio-based epoxy resin containing triazine ring structure and its preparation, which can solve the problems of reducing the content of bio-based in the system, achieve easy operation, and solve the problem of excessive dependence on petrochemical resources. , the effect of high yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

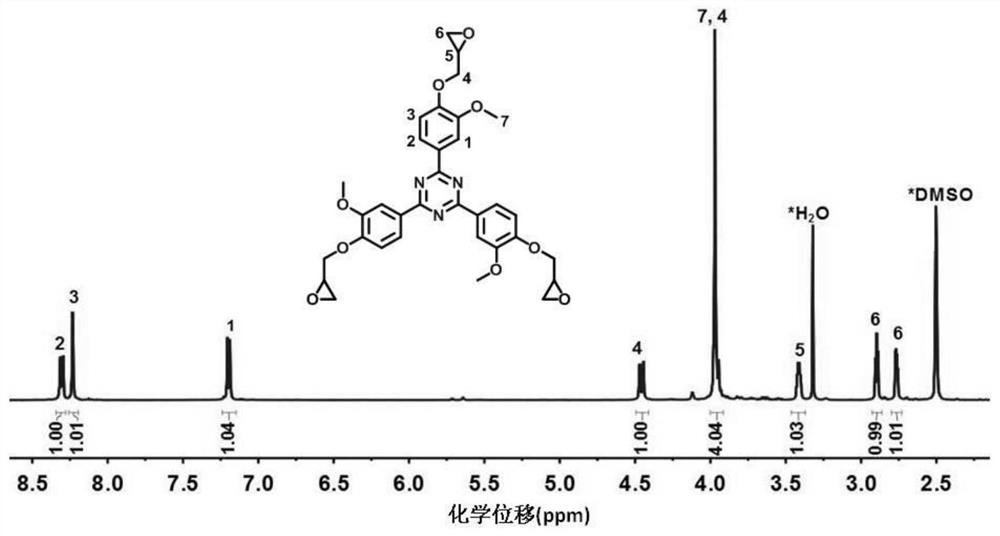

Embodiment 1

[0034] (1) Synthesis of bio-based 4-hydroxy-3methoxybenzonitrile: add 0.81g of anhydrous ferric chloride and 50ml of anhydrous DMF in a 100ml three-necked flask, mechanically stir until completely dissolved, and then successively 1.52g of vanillin and 0.83g of hydroxylamine hydrochloride were added thereto, and the system was reacted at 140°C for 5h. After the reaction, the system was poured into 100 mL of distilled water, extracted with ethyl acetate, separated, and the ethyl acetate layer was dried overnight with anhydrous sodium sulfate. Subsequently, suction filtration was performed, and the solvent was distilled off from the filtrate under reduced pressure to obtain a solid product, which was washed three times with water and dried in vacuum to obtain the bio-based monomer 4-hydroxy-3-methoxybenzonitrile with a yield of 93%.

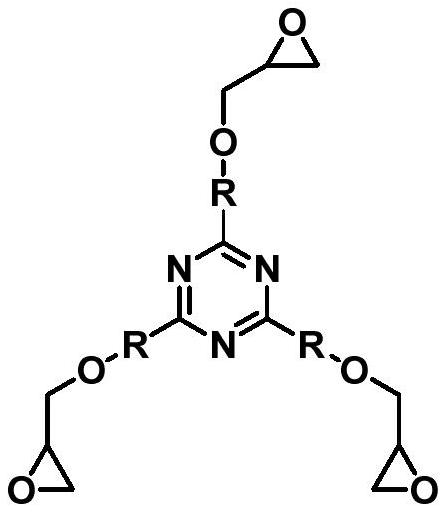

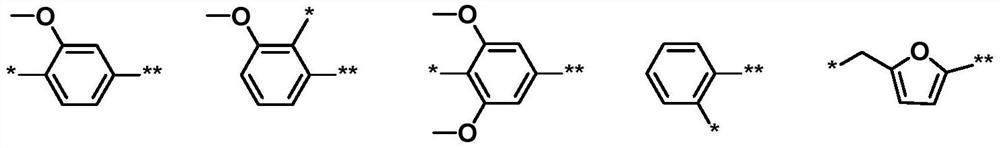

[0035] (2) Synthesis of THMT, a bio-based triphenol monomer containing triazine ring structure: In a 500ml three-necked flask equipped with mechani...

Embodiment 2

[0040] (1) Synthesis of bio-based 4-hydroxy-3,5-dimethoxybenzonitrile: Add 0.97g of anhydrous ferric chloride and 50ml of anhydrous DMF into a 100ml three-necked flask, and mechanically stir until completely dissolved Afterwards, 1.82 g of syringaldehyde and 1.09 g of hydroxylamine hydrochloride were successively added thereto, and the system was reacted at 140° C. for 5 hours. After the reaction, the system was poured into 100ml of distilled water, extracted with ethyl acetate, separated, and the ethyl acetate layer was dried overnight with anhydrous sodium sulfate. Subsequently, suction filtration, the filtrate was distilled off the solvent under reduced pressure to obtain a solid product, which was washed 3 times with water and dried in vacuo to obtain the bio-based monomer 4-hydroxyl-3,5-dimethoxybenzonitrile, the yield 89%.

[0041] (2) Synthesis of THMT-2, a bio-based triphenol monomer containing a triazine ring structure: In a 500ml three-necked flask equipped with mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com