Preparation method of three-dimensional manganese coordination polymer

A coordination polymer, three-dimensional technology, applied in the field of coordination polymers and their preparation, can solve the problems of unsatisfactory stability, high cost, complicated preparation process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, a preparation method of a three-dimensional manganese coordination polymer, the steps are as follows:

[0033] a. Weigh 0.05 mmol of 5,5'-(1,2-phenylene bis(methoxy))diisophthalic acid ligand material and dissolve it in 1.5 ml of N,N-dimethylformamide , then add 0.05 mmol bpmp nitrogen-containing ligand to obtain a ligand solution;

[0034] b. Weigh 0.20 mmol of manganese nitrate and dissolve it in 7.5 milliliters of deionized water to obtain a manganese salt solution;

[0035] c. the ligand solution prepared in the step a and the manganese salt solution prepared in the step b are mixed in a reaction kettle with a Teflon liner with a volume of 15 milliliters to obtain a mixture of reactants solution; at 85°C, keep the mixed solution of reactants at a constant temperature for 72h for hydrothermal synthesis reaction, then cool down to room temperature with a rate gradient of 10°C / h, and then filter the product solution to obtain light yellow rod-shape...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

[0038] In this embodiment, a preparation method of a three-dimensional manganese coordination polymer, the steps are as follows:

[0039] a. Weigh 0.05 mmol of 5,5'-(1,2-phenylene bis(methoxy))diisophthalic acid ligand material and dissolve it in 1.5 ml of N,N-dimethylformamide , then add 0.05 mmol bpmp nitrogen-containing ligand to obtain a ligand solution;

[0040] b. Weigh 0.20 mmol of manganese nitrate and dissolve it in 7.5 milliliters of deionized water to obtain a manganese salt solution;

[0041] c. the ligand solution prepared in the step a and the manganese salt solution prepared in the step b are mixed in a reaction kettle with a Teflon liner with a volume of 15 milliliters to obtain a mixture of reactants solution; at 85°C, keep the mixed solution of reactants at a constant temperature for 48 hours for hydrothermal synthesis reaction, then cool down to room temperature at a rate o...

Embodiment 3

[0054] This embodiment is basically the same as the previous embodiment, and the special features are:

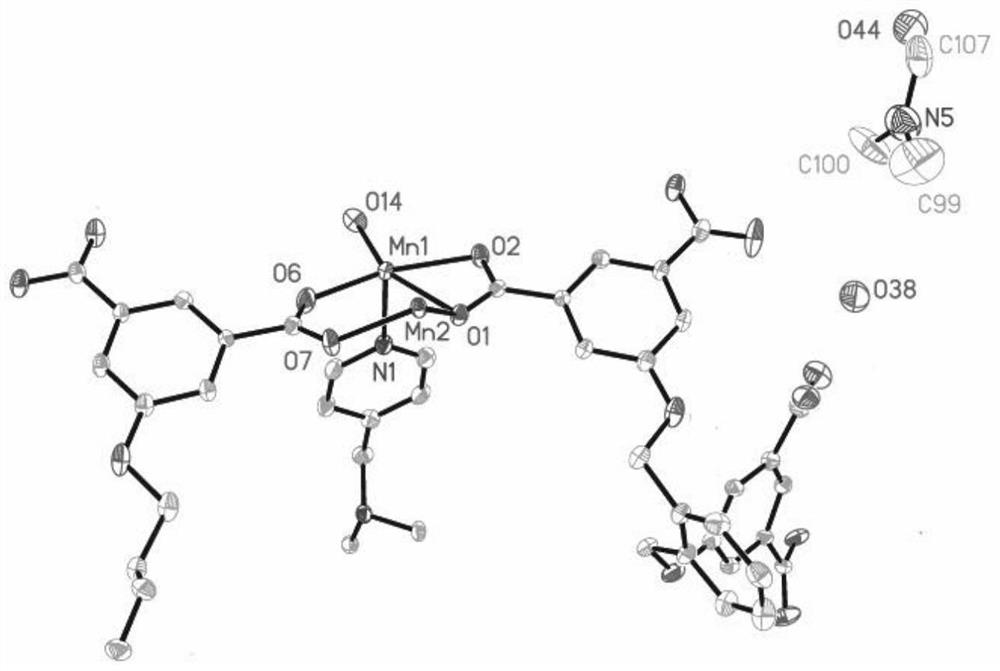

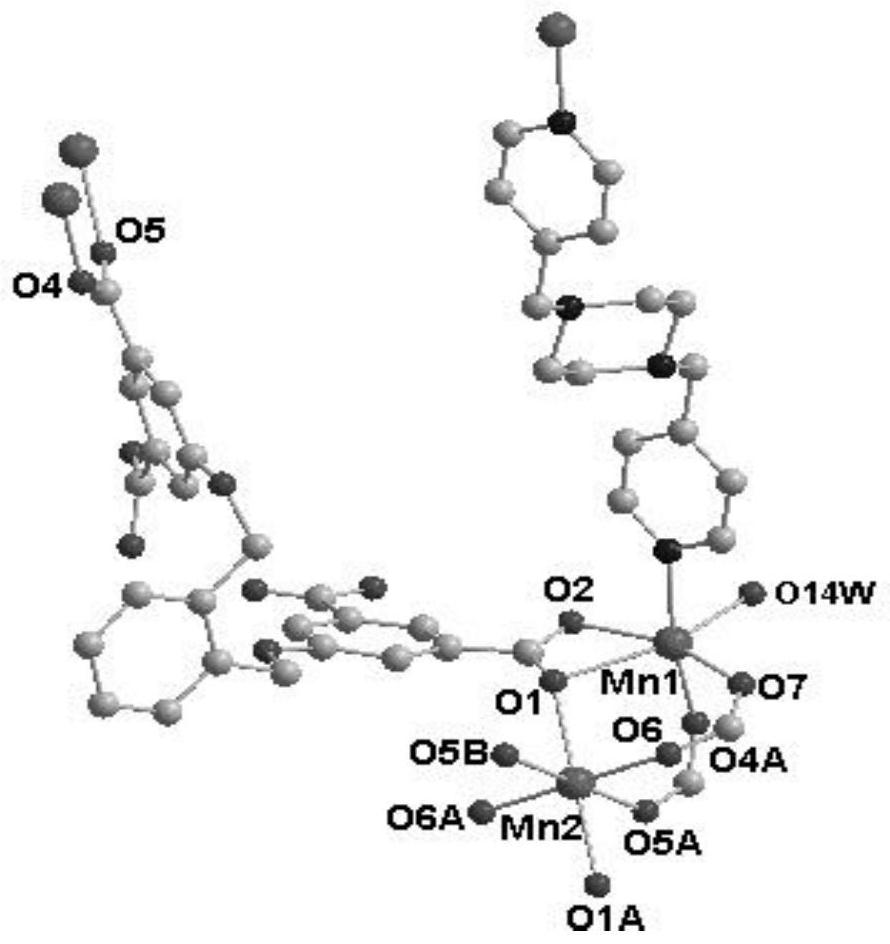

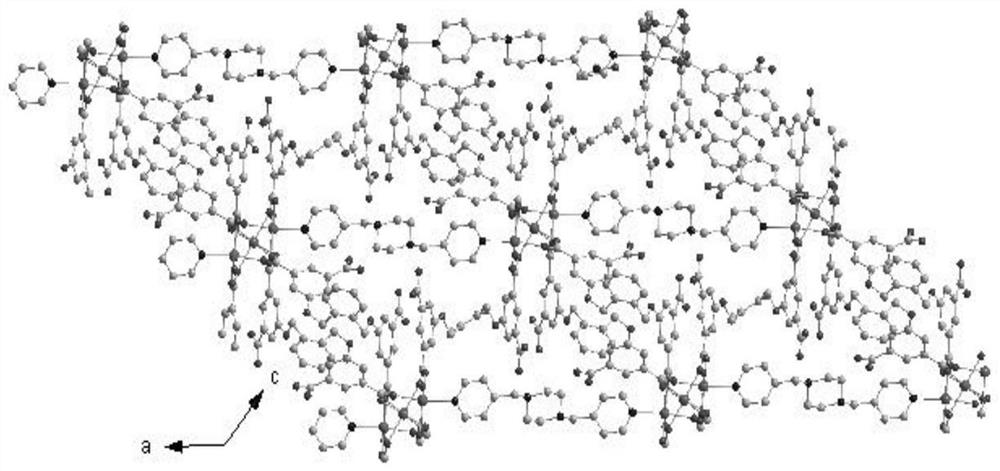

[0055] In this example, see figure 1 ,

[0056] In this embodiment, a preparation method of a three-dimensional manganese coordination polymer, the steps are as follows:

[0057] a. Weigh 0.05 mmol of 5,5'-(1,2-phenylene bis(methoxy))diisophthalic acid ligand material and dissolve it in 1.5 ml of N,N-dimethylformamide , then add 0.05 mmol bpmp nitrogen-containing ligand to obtain a ligand solution;

[0058] b. weigh 0.25 millimoles of manganese nitrate and dissolve it in 7.5 milliliters of deionized water to obtain a manganese salt solution;

[0059] c. the ligand solution prepared in the step a and the manganese salt solution prepared in the step b are mixed in a reaction kettle with a Teflon liner with a volume of 15 milliliters to obtain a mixture of reactants solution; at 100°C, keep the mixed solution of reactants at a constant temperature for 48 hours for hydrothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com