A kind of rubber antioxidant and preparation method thereof

A technology of rubber anti-aging agent and amine anti-aging agent, which is applied in the field of rubber anti-aging agent, and can solve problems such as waste of anti-aging agent, weakening of aging effect, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

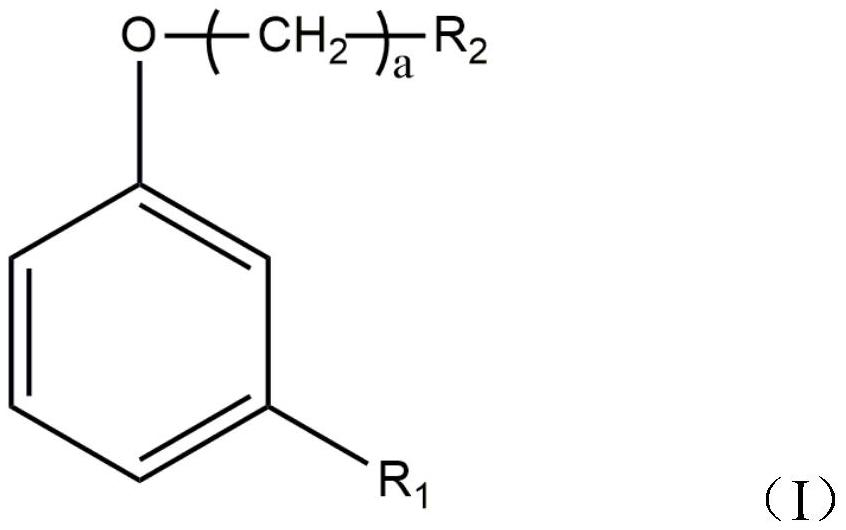

Method used

Image

Examples

Embodiment 1

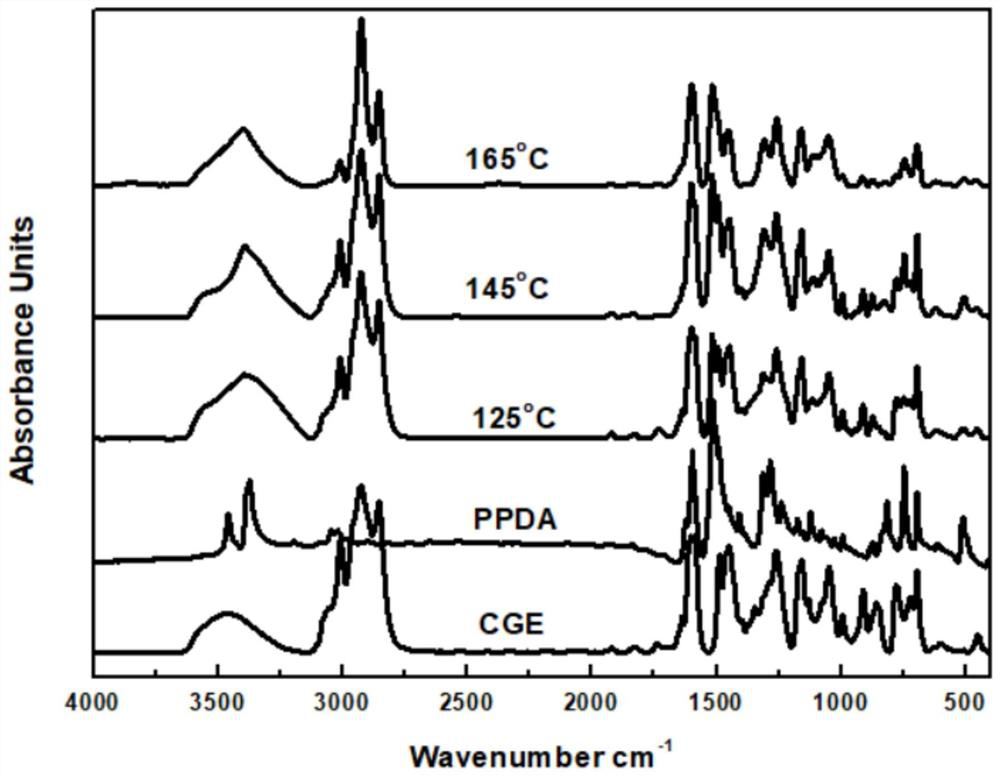

[0028] Place CGE in the reactor, add amine antioxidant PPDA, and add a magnetic stirrer to control the effective reaction between CGE and amine antioxidant. The molar ratio of amino group is 1:1, the reaction temperature is controlled at 155 ° C, and the reaction is stirred for 3 hours. , stop heating to obtain product In step (1), control the stirring speed to be 150 rpm to obtain the final product.

[0029] Take 100 parts of SBR, 40 parts of carbon black N330, 5 parts of zinc oxide, 2 parts of stearic acid, 4 parts of Example 1 antioxidant, 4 parts of paraffin, 1.5 parts of accelerator CZ, and 2 parts of sulfur.

[0030] The SBR was uniformly blended on a two-roll mill, and the other ingredients except carbon black were added. After mixing uniformly, carbon black was added. The obtained mixed rubber was pressed and cut in a vulcanizer at 170°C to test its performance. The test results are shown in Table 1 and Table 2.

Embodiment 2

[0032] The CGE was placed in the reactor, the amine antioxidant was added, and a magnetic stirring bar was added to control the molar ratio of the amino group in the effective reaction between CGE and the amine antioxidant to be 1:1, and the reaction temperature was controlled to 160 ° C, and the reaction was stirred for 3 hours. Stop heating to obtain product In step (1), the stirring speed is controlled to be 150 rpm to obtain the final product.

[0033] Take 100 parts of SBR, 40 parts of carbon black N330, 5 parts of zinc oxide, 2 parts of stearic acid, 4 parts of Example 2 antioxidant, 4 parts of paraffin, 1.5 parts of accelerator CZ, and 2 parts of sulfur.

[0034] The SBR was uniformly blended on a two-roll mill, and the other ingredients except carbon black were added. After mixing uniformly, carbon black was added. The obtained mixed rubber was pressed and cut in a vulcanizer at 170°C to test its performance. The test results are shown in Table 1 and Table 2.

Embodiment 3

[0036] The CGE was placed in the reactor, the amine antioxidant was added, and a magnetic stirring bar was added to control the molar ratio of the amino group in the effective reaction between CGE and the amine antioxidant to be 1:1, and the reaction temperature was controlled at 165 ° C, and the reaction was stirred for 3 hours. Stop heating to obtain product In step (1), the stirring speed is controlled to be 150 rpm to obtain the final product.

[0037] Take 100 parts of SBR, 40 parts of carbon black N330, 5 parts of zinc oxide, 2 parts of stearic acid, 4 parts of Example 3 antioxidant, 4 parts of paraffin, 1.5 parts of accelerator CZ, and 2 parts of sulfur.

[0038] The SBR was uniformly blended on a two-roll mill, and the other ingredients except carbon black were added. After mixing uniformly, carbon black was added. The obtained mixed rubber was pressed and cut in a vulcanizer at 170°C to test its performance. The test results are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com