High-temperature-resistant viscosity-reducing oil-displacing agent for thickened oil steam chemical flooding and preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The water of 200kg is joined in the reactor, control temperature 30 ℃, add 100kg phenol ether carboxylate (R 1 =8, n=15) and 200kg fatty alcohol polyoxyethylene ether (R 2 =8, n=20), stir and dissolve evenly, then add methanol 100kg, after fully stirring, add 400kg α-sodium olefin sulfonate (R 3 =9, n=2), and stirred evenly to obtain a high-temperature-resistant viscosity-reducing oil-displacing agent.

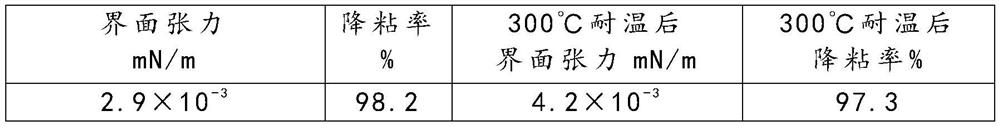

[0041] The detection data is as follows:

[0042]

Embodiment 2

[0044] The water of 200kg is joined in the reactor, control temperature 32 ℃, add 300kg phenol ether carboxylate (R 1 =10, n=10) and 100kg fatty alcohol polyoxyethylene ether (R 2 =14, n=9), stir and dissolve evenly, then add ethanol 100kg, after fully stirring, add 300kgα-sodium sulfonate (R 3 =10, n=3), and stirred evenly to obtain a high temperature resistant viscosity reducing oil displacement agent.

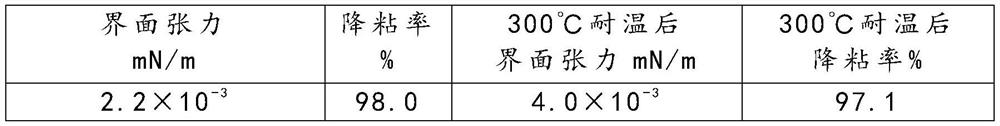

[0045] The detection data is as follows:

[0046]

Embodiment 3

[0048] The water of 200kg is joined in reactor, control temperature 35 ℃, add 200kg phenol ether carboxylate (R 1 =12, n=6) and 100kg fatty alcohol polyoxyethylene ether (R 2 =10, n=15), stir and dissolve evenly, then add isopropanol 150kg, after fully stirring, add 350kgα-sodium olefin sulfonate (R 3 =13, n=1), and stirred evenly to obtain a high temperature resistant viscosity reducing oil displacement agent.

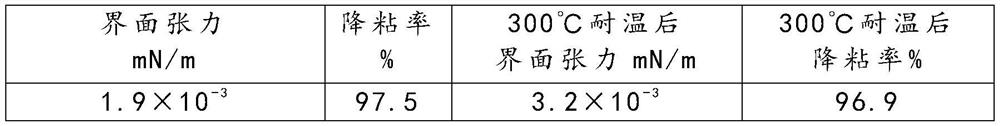

[0049] The detection data is as follows:

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com