Structure and method of combined composite sleeper

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

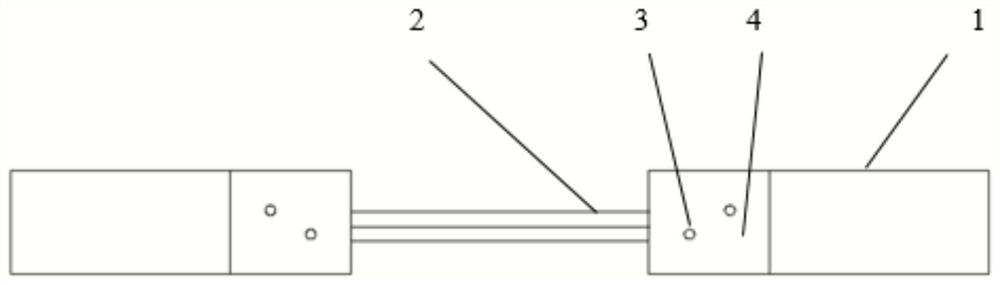

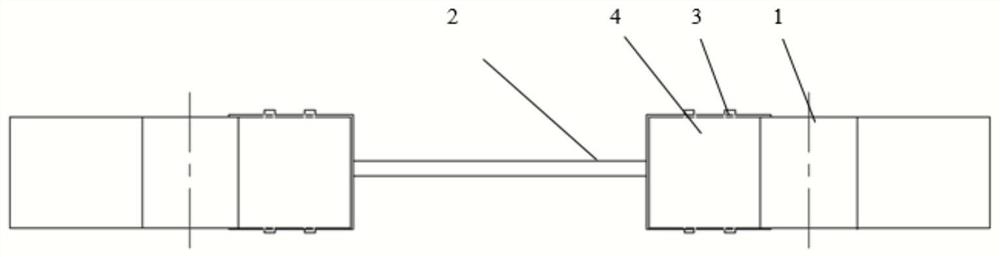

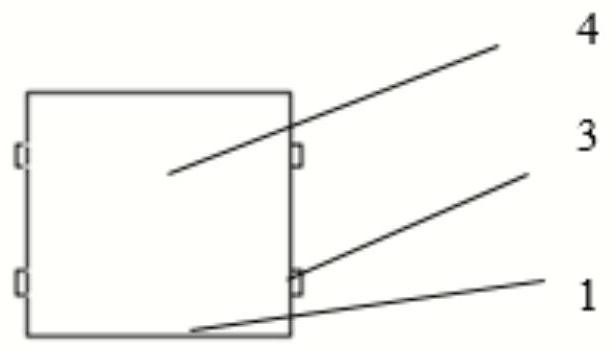

[0061] Embodiment 1.1: a kind of composite sleeper device based on steel structure skeleton, it comprises: steel structure 1, composite sleeper 2 based on scrap tire or plastics. The structural design of the sleeper mainly depends on the stress situation and material characteristics. The sleeper in this embodiment will be introduced below in combination with the stress characteristics and material properties of the sleeper.

[0062] 1. Dimensions and materials

[0063] The short beam supporting the composite sleeper 2 on the elastic foundation, under the action of the load from the rail, the bottom of the composite sleeper generates a reaction force against the composite sleeper, and each section of the composite sleeper bears the bending stress, and according to the design regulations: the upper part of the composite sleeper interface It is "-" when it is pulled, and "+" when the lower part is pulled.

[0064] 1. Shape of composite sleeper

[0065] In the structure of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com