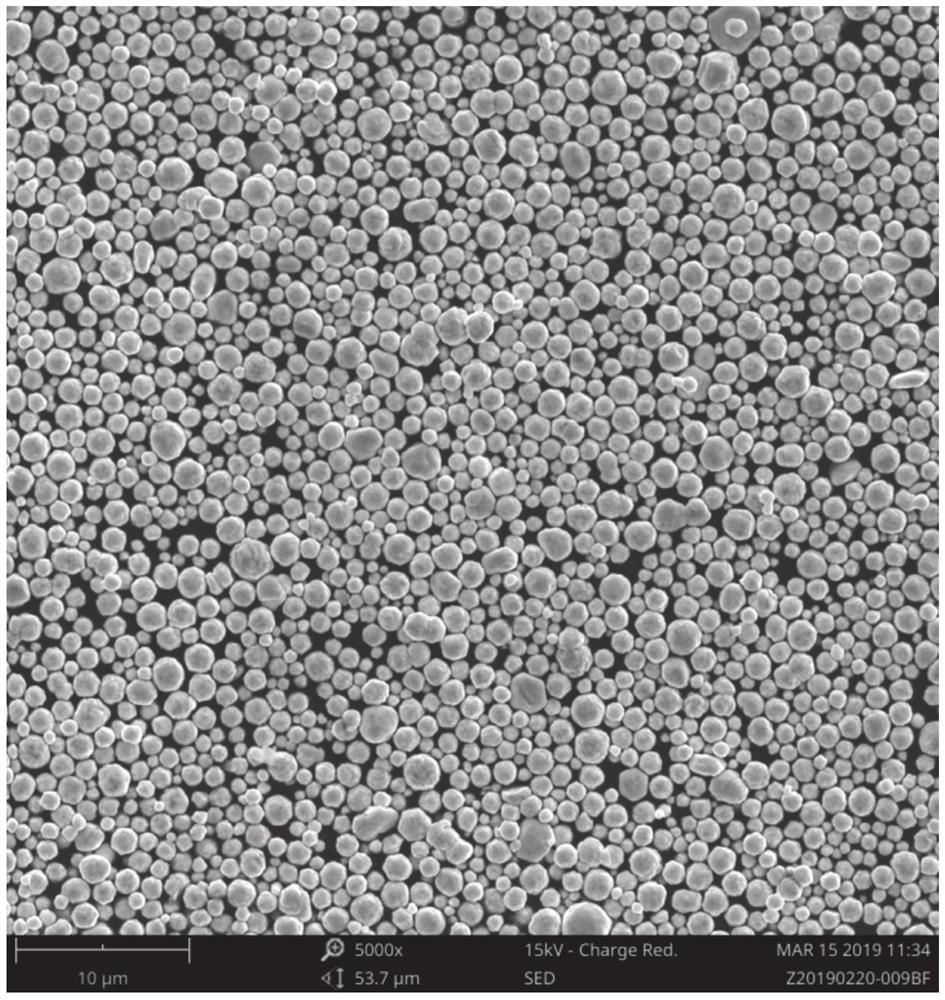

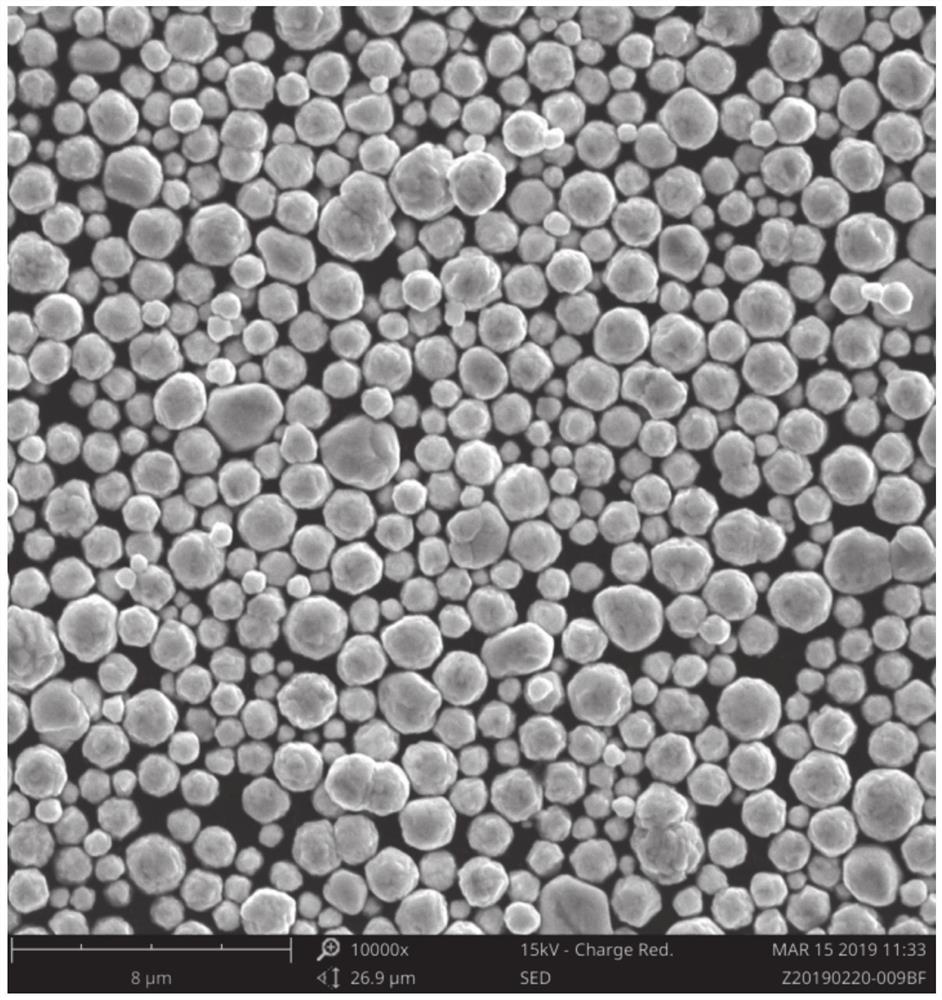

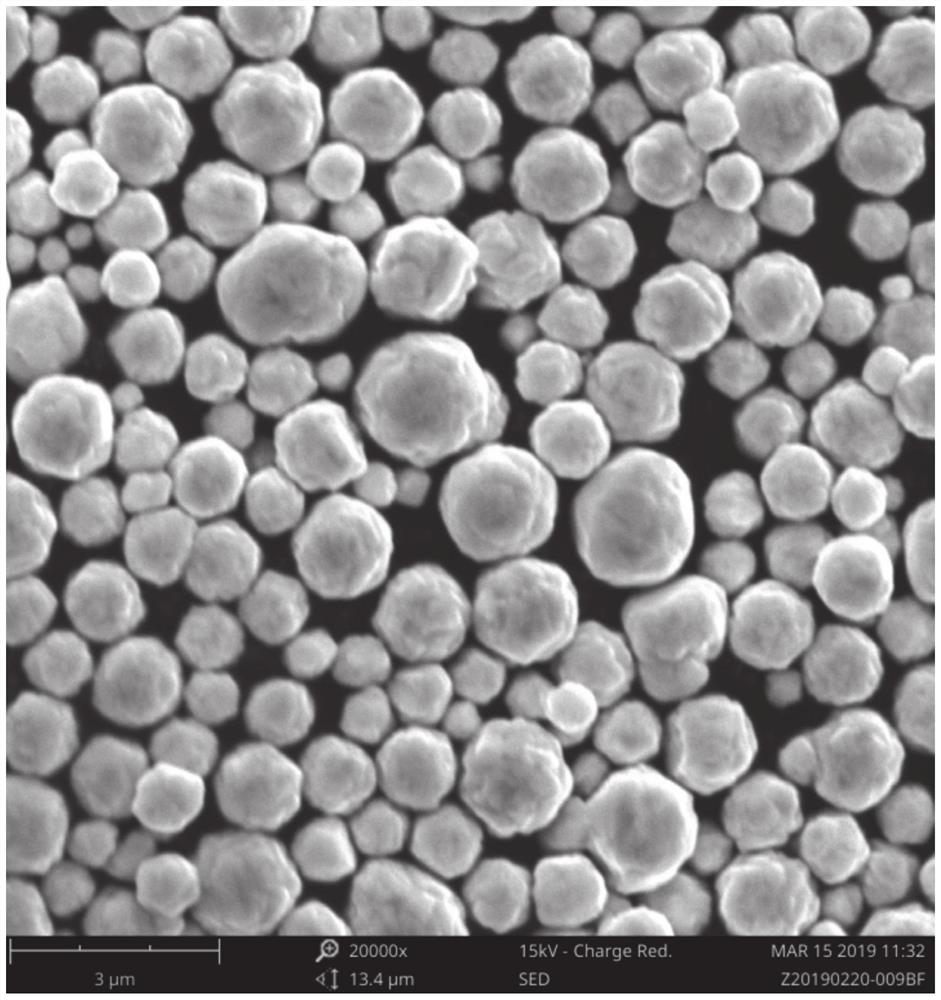

Silver powder for conductive silver paste of ceramic filter and preparation method of silver powder

A ceramic filter, conductive silver paste technology, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of uneven silver layer, low effective conductivity, affecting product Q value , silver layer tensile surface roughness and other issues, to achieve the effect of good electrical conductivity and solderability, low cost, high uniformity of morphology and particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The method for preparing the silver powder that is used for ceramic filter conductive silver paste provided by the invention, it comprises:

[0017] Step 1, prepare solution A: add PVP and potassium sulfate to the reaction kettle, then add deionized water, stir and dissolve evenly and set aside; step 2, prepare solution B: add deionized water to the reaction kettle, then add VC and Hydrogen peroxide, stir and dissolve evenly for later use; step 3, prepare solution C: add deionized water to the reaction kettle, then add silver nitrate, stir and dissolve evenly and then set aside; step 4, reduction reaction: first quickly add solution B to solution A , then add solution C to solution A, stir after completion, and prepare silver powder; step 5, post-processing: adjust the pH value of the solution, then wash and filter with a filter plate, remove excess water, and repeat the washing process several times, Silver powder is deposited, washed and dried to obtain silver powder....

Embodiment 1

[0027] A method for preparing silver powder for ceramic filter conductive silver paste, comprising:

[0028] Step 1, prepare A solution: add 20g of PVP and 1.5g of potassium sulfate to the reaction kettle, then add 500g of deionized water, stir and dissolve evenly and set aside; keep the temperature range at 30-35°C during this process. PVP uses K25's PVP.

[0029] Step 2, prepare solution B: add 220g of deionized water to the reaction kettle, then add 52g of VC and 2.5g of hydrogen peroxide in sequence, stir to dissolve evenly and set aside; keep the temperature range at 30-35°C during the process.

[0030] Step 3, prepare solution C: add 600g of deionized water to the reaction kettle, then add 100g of silver nitrate, stir to dissolve evenly and set aside; keep the temperature range at 30-35°C during this process.

[0031] Step 4, reduction reaction: first quickly add solution B to solution A, then add solution C to solution A at a flow rate of 60ml / min, and stir for 10 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com