Silver powder used for crystalline silicon solar PERC cell silver paste and preparation method thereof

A solar energy and crystalline silicon technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of destroying passivation films, reducing the effect of passivation and improving efficiency of PERC cells, etc., to meet process requirements, morphology and particle size The effect of high diameter uniformity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

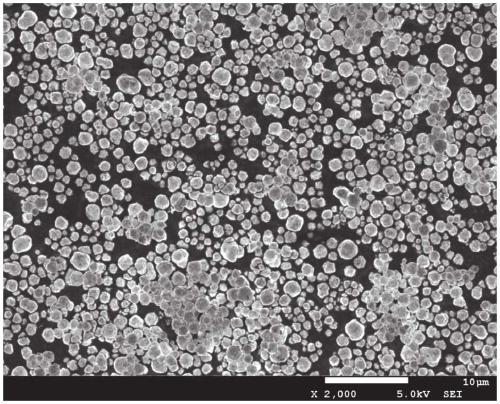

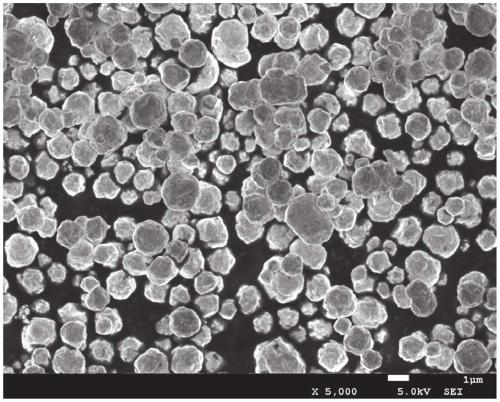

[0020] The method for preparing the silver powder used for the silver paste of crystalline silicon solar PERC battery provided by the invention comprises:

[0021] Step 1, prepare solution A: add gum arabic powder or gelatin to the reaction kettle, then add deionized water, stir and dissolve evenly, and then set aside; step 2, prepare solution B: add deionized water to the reaction kettle, and then add iso Ascorbic acid and sodium erythorbate, stir to dissolve evenly and set aside; step 3, prepare C solution: add deionized water to the reaction kettle, then add gum arabic powder or gelatin, fully stir to dissolve, then add silver nitrate, stir to dissolve evenly and set aside Step 4, reduction reaction: first add solution B to solution A, then add solution C to solution A, stir after completion, and prepare silver powder; step 5, heat up, add sodium hydroxide or ammonia solution, and heat up again Keep, and then discharge and wash the powder; step 6, wash and filter with a fil...

Embodiment 1

[0033] A method for preparing silver powder for crystalline silicon solar PERC cell silver paste, comprising:

[0034] Step 1, prepare solution A: add 6g of gum arabic powder or gelatin to the reaction kettle, then add 550g of deionized water, stir to dissolve evenly and set aside; keep the temperature range at 46°C during this process.

[0035] Step 2, prepare solution B: add 240g of deionized water to the reaction kettle, then add 40g of erythorbic acid and 15g of sodium erythorbate in sequence, stir and dissolve evenly, and set aside; keep the temperature range at 47°C during the process.

[0036]Step 3, prepare solution C: add 600g of deionized water to the reaction kettle, then add 2.5g of gum arabic powder or gelatin, fully stir to dissolve, then add 100g of silver nitrate, stir to dissolve evenly and set aside; keep the temperature range in the process 42°C.

[0037] Step 4, reduction reaction: first add solution B to solution A at a flow rate of 26ml / min, then add sol...

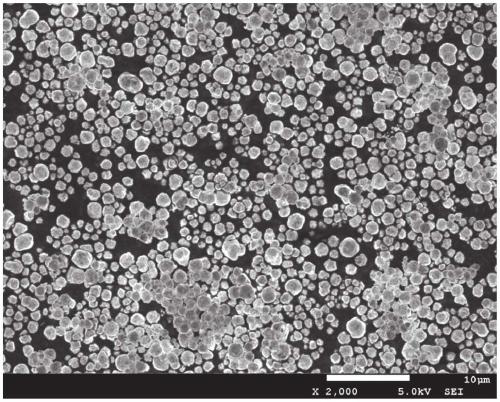

Embodiment 2

[0043] A method for preparing silver powder for crystalline silicon solar PERC cell silver paste, comprising:

[0044] Step 1, prepare solution A: add 6g of gum arabic powder or gelatin to the reaction kettle, then add 500g of deionized water, stir to dissolve evenly and set aside; keep the temperature range at 45°C during this process.

[0045] Step 2, prepare solution B: add 220g of deionized water to the reaction kettle, then add 40g of erythorbic acid and 15g of sodium erythorbate in sequence, stir and dissolve evenly and set aside; keep the temperature range at 45°C during the process.

[0046] Step 3, prepare solution C: add 600g of deionized water to the reaction kettle, then add 2.5g of gum arabic powder or gelatin, fully stir to dissolve, then add 100g of silver nitrate, stir to dissolve evenly and set aside; keep the temperature range in the process 40°C.

[0047] Step 4, reduction reaction: first add solution B to solution A at a flow rate of 26ml / min, then add sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com