Catalyst for plasma decomposition of carbon dioxide and preparation method thereof, catalytic system for plasma decomposition of carbon dioxide and application thereof

A carbon dioxide, catalytic system technology, applied in the field of ion decomposition, can solve the problems of discharge power influence, low energy efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing a catalyst for plasma decomposition of carbon dioxide described in the foregoing technical solution, comprising the following steps:

[0032] (1) impregnating the spherical carrier in a non-noble metal salt solution to obtain a catalyst precursor; the impregnation time is 0.5 to 2 hours;

[0033] The mass of non-precious metal ions in the non-precious metal salt solution is based on the mass of the corresponding oxide, and the mass of the non-precious metal oxide is 1-40% of the mass of the spherical carrier after drying;

[0034] (2) After the catalyst precursor obtained in the step (1) is dried, discharge treatment is carried out under an argon atmosphere to obtain a catalyst for plasma decomposition of carbon dioxide.

[0035] In the invention, the spherical carrier is impregnated in a non-noble metal salt solution to obtain a catalyst precursor. The spherical carrier is preferably obtained by drying the raw...

Embodiment 1

[0059] Take 15g of alumina pellets, the diameter of spherical alumina is about 2-3mm, and then pretreat in an oven at 110°C for 3 hours; obtain alumina pellets for use;

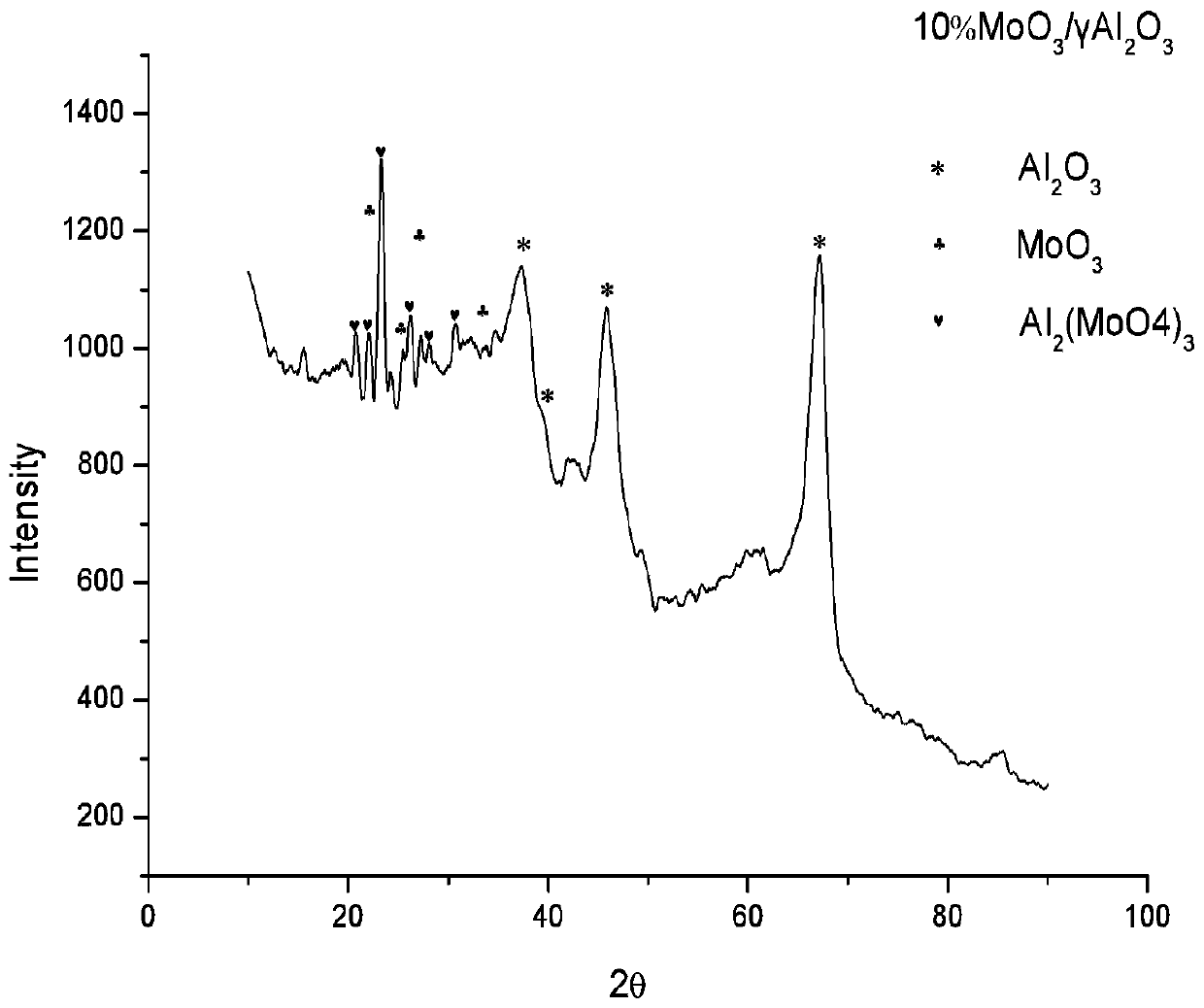

[0060] According to the mass of molybdenum oxide in the shaped catalyst being 10% of the mass of the carrier, a certain concentration of ammonium molybdate solution was prepared; the alumina pellets were immersed in the solution for 1 hour, and after drying overnight at 120°C, in an Ar atmosphere, controlled 50W Discharge input power, discharge treatment 1h, obtain catalyst, carry out XRD analysis to the prepared catalyst, the result is as follows figure 2 shown by figure 2 It can be seen that the obtained catalyst is 10% MoO 3 / Al 2 o 3 , namely MoO 3 It is 10% of the total mass of the catalyst, and the non-noble metal exists in the form of oxide on the surface of the spherical carrier.

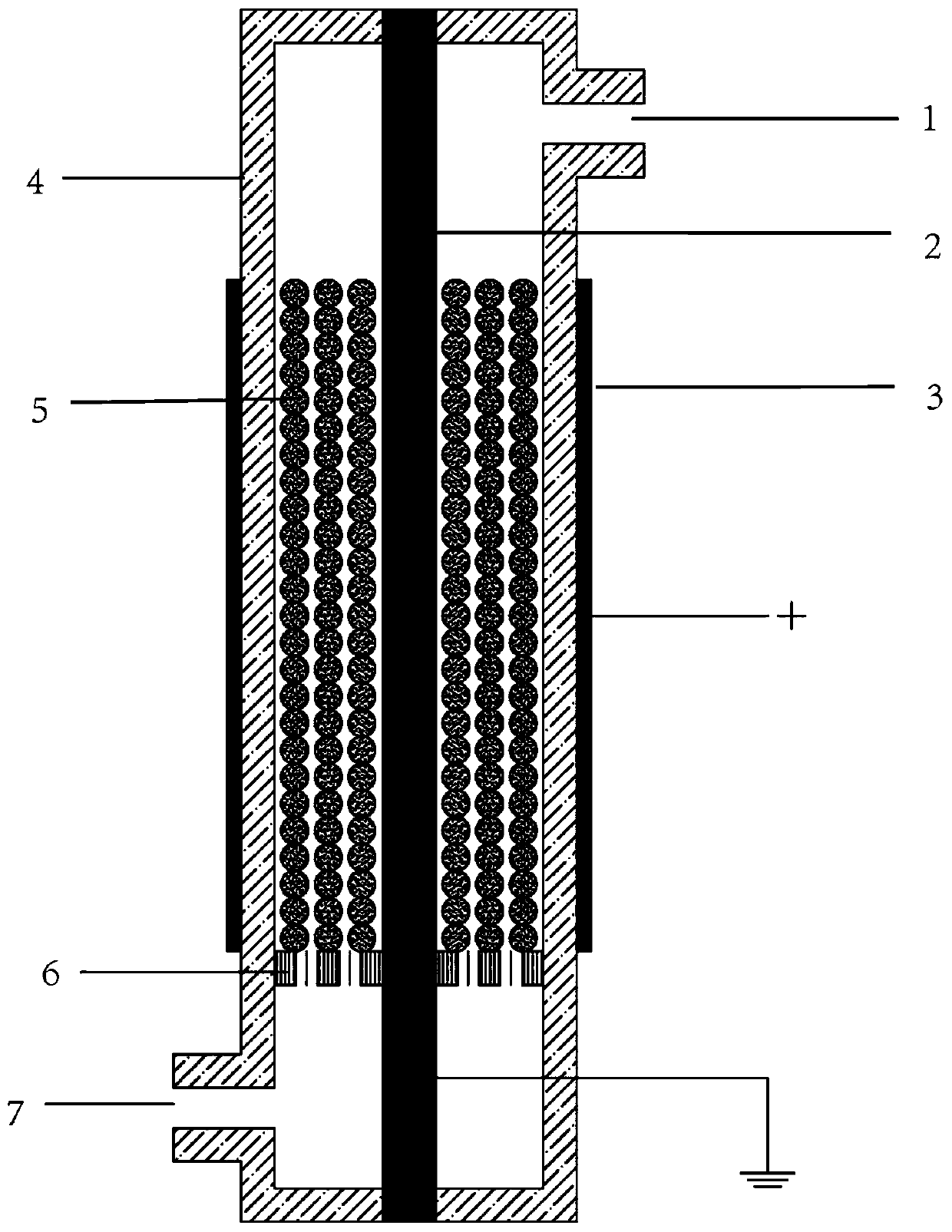

[0061] according to figure 1 The way to provide wire barrel type dielectric barrier discharge plasma reactor, whe...

Embodiment 2

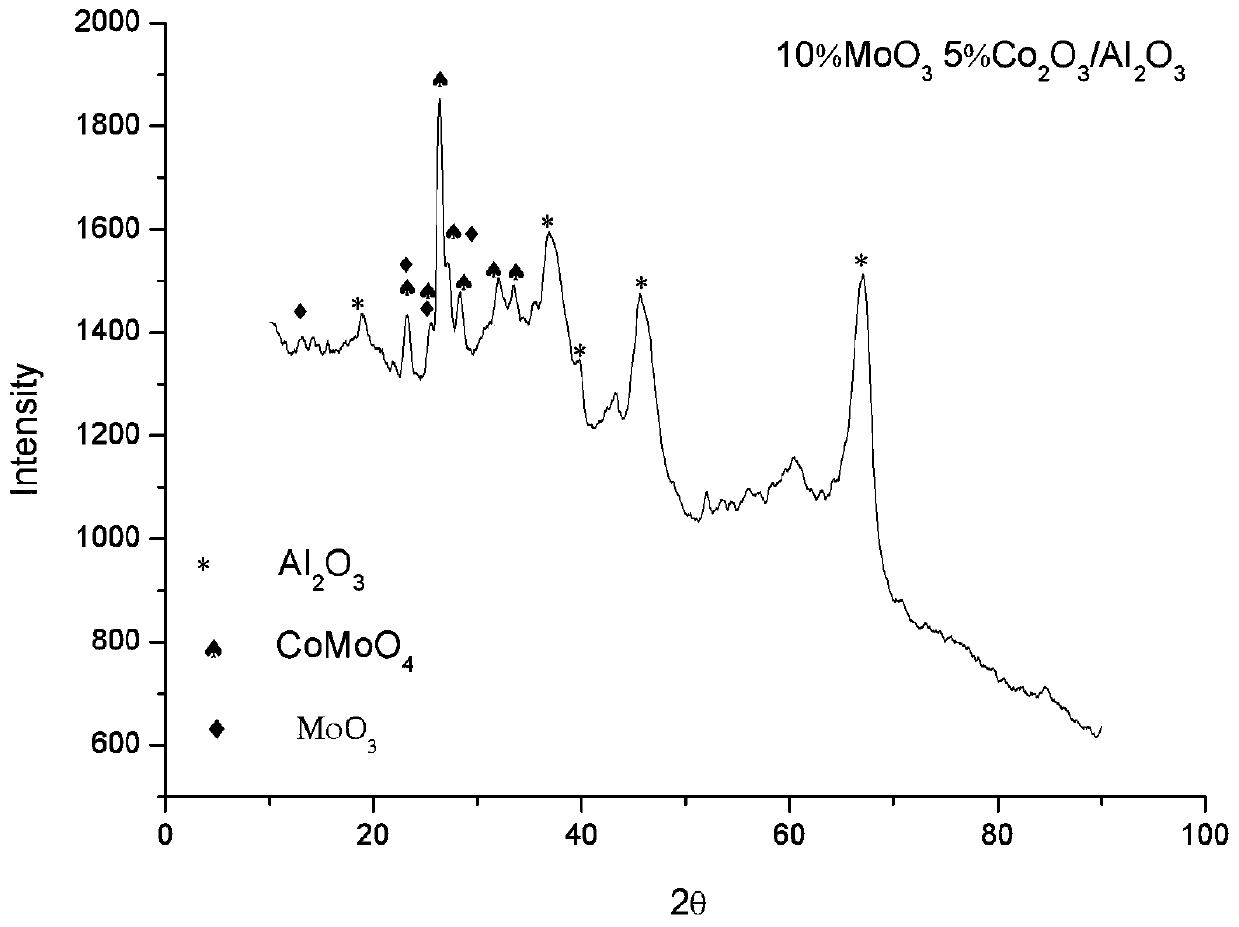

[0065] Prepare the catalyst according to the method of Example 1, the difference is that the impregnation solution used in the impregnation process is a cobalt nitrate solution, the concentration of the solution is prepared according to the mass of cobalt oxide in the shaped catalyst as 5% of the carrier mass, and the impregnation time is 1h to obtain the catalyst. The prepared catalyst carries out XRD analysis, it can be known that the obtained catalyst is 5% Co 2 o 3 / Al 2 o 3 .

[0066]A plasma reactor was provided and used for the decomposition of carbon dioxide in the same manner as in Example 1, with the difference that the effective discharge power was 7.0W.

[0067] Analysis of the effluent gas by gas chromatography can confirm that the carbon dioxide is decomposed into carbon monoxide and oxygen after flowing through the plasma reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com