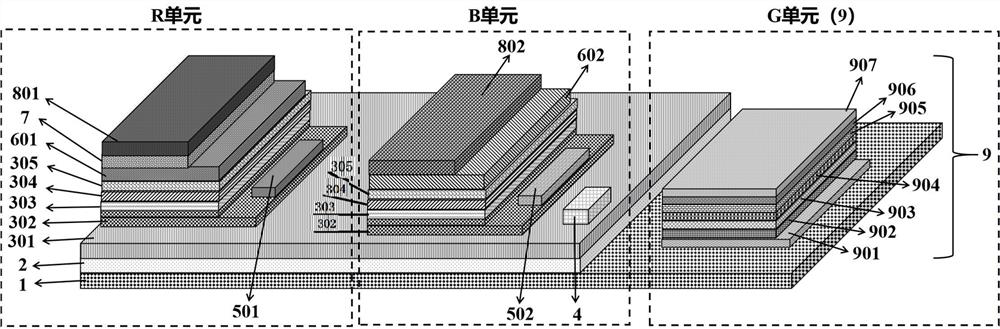

Triode control type hybrid structure full-color display device and manufacturing method thereof

A hybrid structure and display device technology, which is applied in semiconductor/solid-state device manufacturing, static indicators, electric solid-state devices, etc., can solve problems such as uneven coating of luminous media, unfavorable large-area production, and unfavorable high-integration system construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

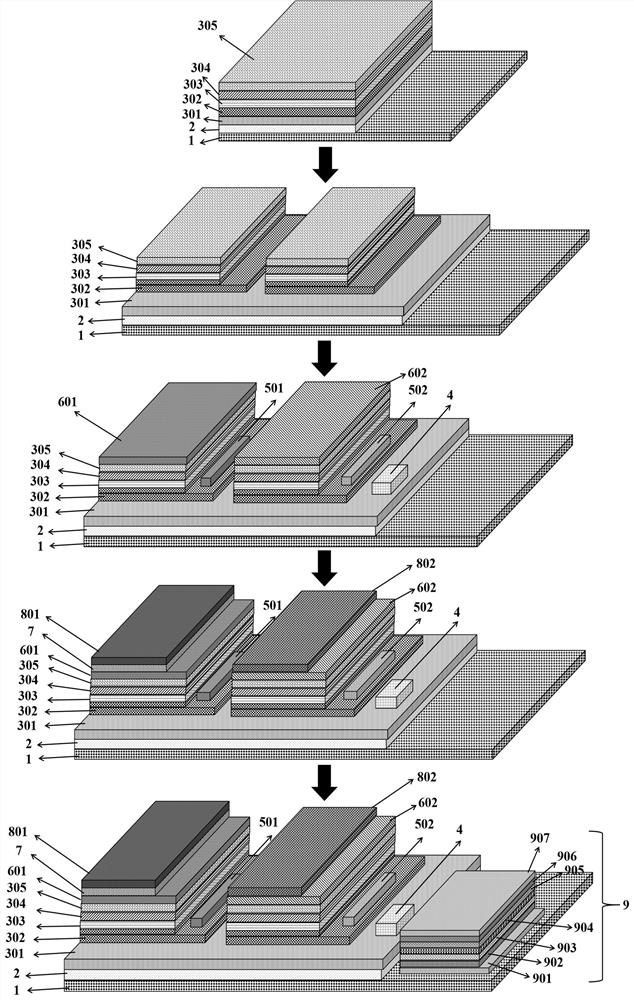

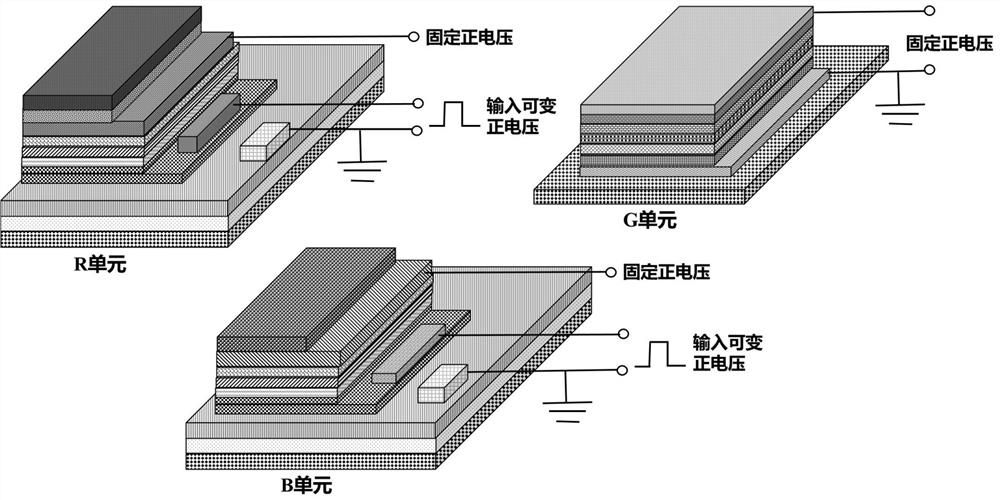

[0095] In this embodiment, the substrate 1 is a sapphire substrate, and is an a-plane, the material used for the buffer layer 2 is AlN, and the main material of the epitaxial layer is a GaN-based material. Specifically, the first layer on the buffer layer The semiconductor layer is an N-GaN layer, the second semiconductor layer on the buffer layer is a P-GaN layer, the third semiconductor layer on the buffer layer is an N-GaN layer, and the blue light emitting layer 304 is a three-period In a Ga 1-a N quantum well active layer and Al b Ga 1-b A hole blocking layer or an electron blocking layer composed of N, and the fourth semiconductor layer on the buffer layer is P-GaN. The first contact electrode 4 is a gold-copper electrode, the second contact electrode SCE1501 and the third contact electrode SCE2502 are gold-copper electrodes, and the transparent fourth contact electrode TCE1601 and fifth contact electrode TCE2602 are both indium tin oxide (ITO). The light conversion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com