High-efficiency automatic straw chopping and kneading machine

A straw, automatic technology, used in cutters, harvesters, cutting equipment and other directions, can solve the problems of large vibration and noise, affecting the environment and high power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the technical solution in the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiment of the present invention. The embodiment takes corn stalks as an example, which is only a part of the embodiments of the present invention, not all embodiments .

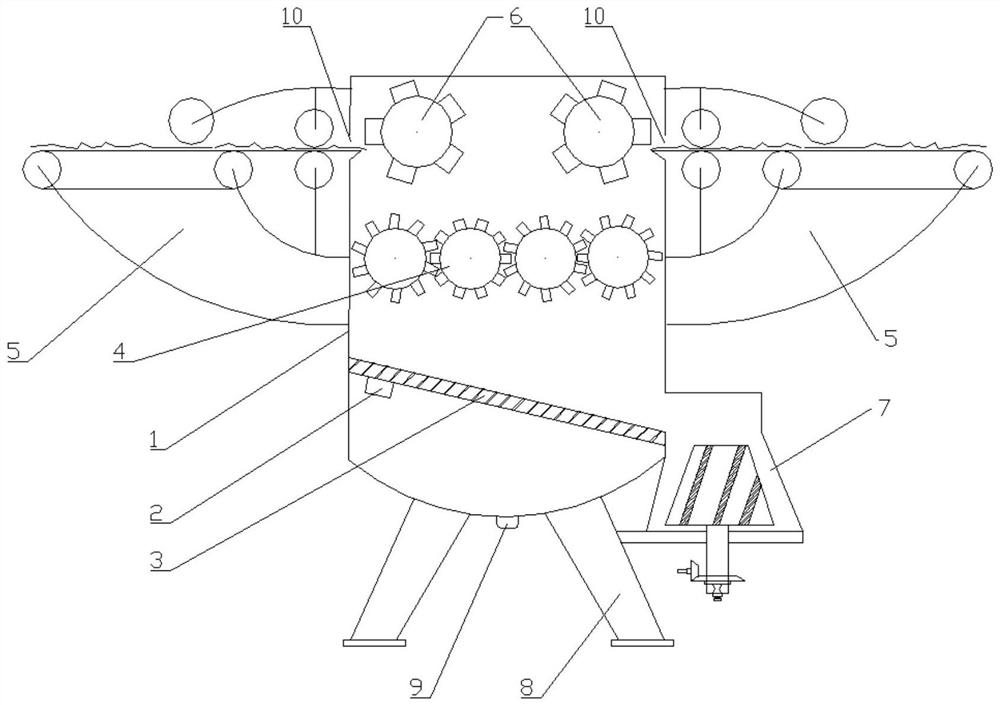

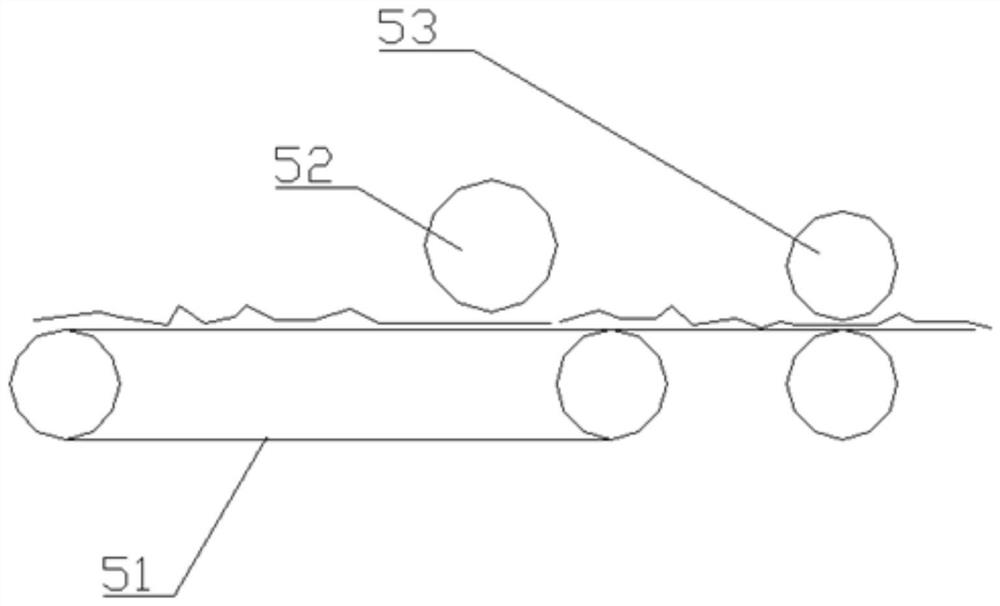

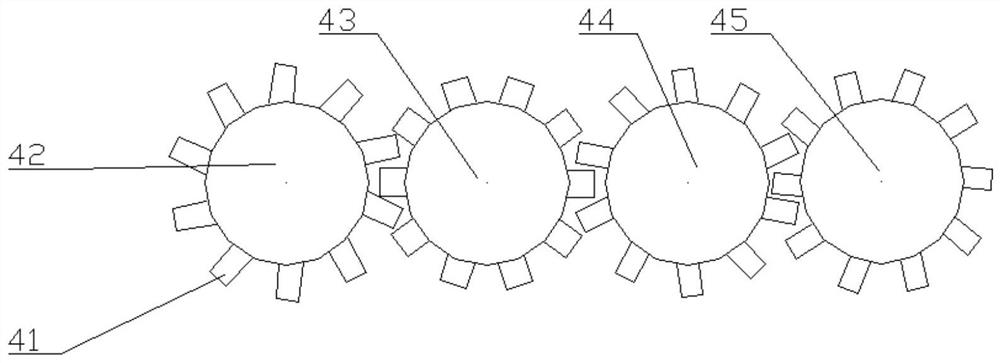

[0020] Such as figure 1 As shown, a high-efficiency automatic straw cutting and rubbing machine mainly includes a rubbing box 1, a feeding mechanism 5, a guillotine cutting mechanism 6, a class I rubbing mechanism 4, a class II rubbing mechanism 7 and other components. Both sides of the upper outer wall of the kneading box 1 are provided with openings 10, and the two openings 10 are externally connected with a feeding mechanism 5, and the upper part of the kneading box 1 is equipped with two guillotine cutting mechanisms 6 near the openings 10. The power of the cutting mechanism 6 is input by the belt pulley, and the center o...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap