Special high strength 7-series aluminum-based composite material for 3D printing and preparation method thereof

An aluminum-based composite, 3D printing technology, applied in the direction of additive processing, energy efficiency improvement, process efficiency improvement, etc., can solve problems such as limiting application, reducing mechanical properties, and 7 series aluminum alloys are prone to cracks, so as to improve mechanical properties. Effects of performance, suppression expansion, and mechanical performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

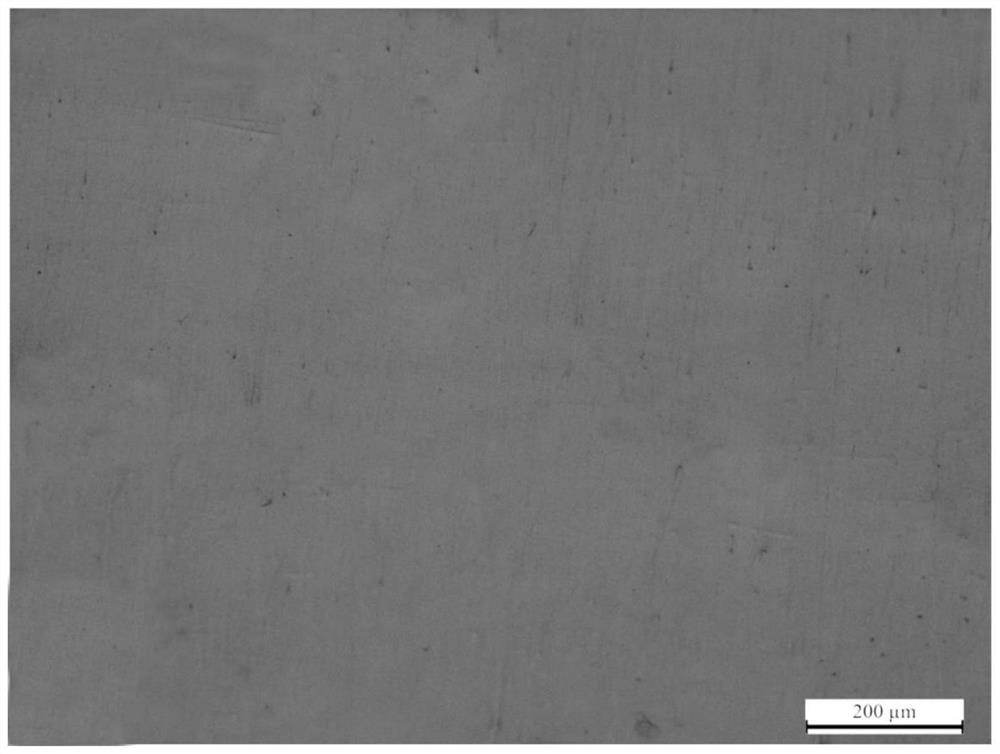

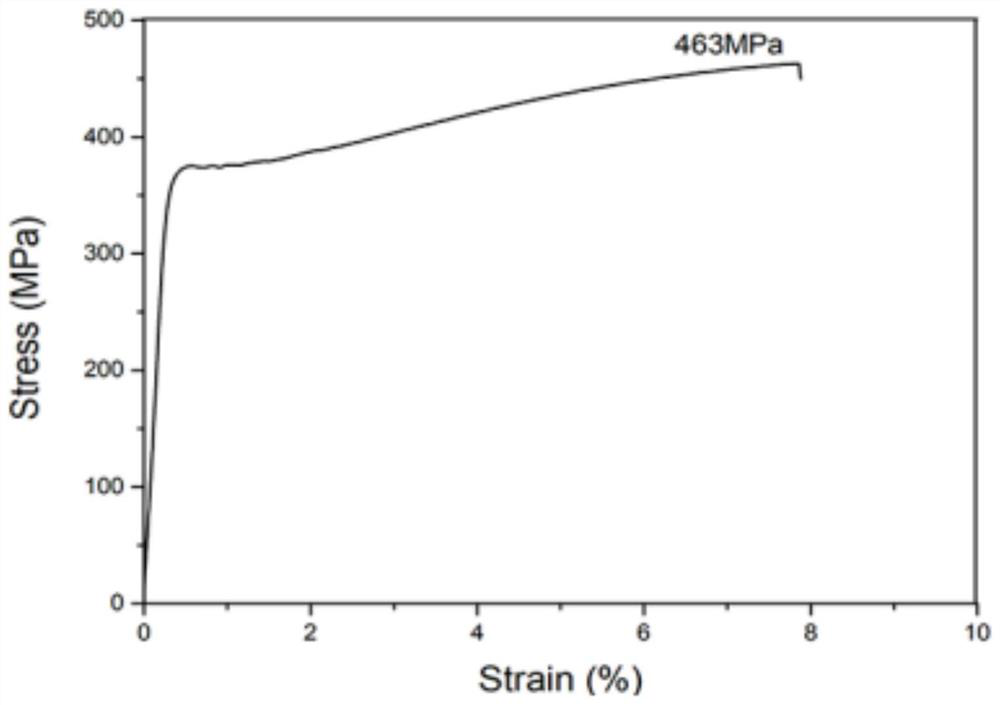

Embodiment 1

[0027] A 7-series aluminum-based composite material without cracks, comprising 7-series aluminum alloy powder, copper-based alloy powder, and erbium oxide powder, wherein the mass fraction of erbium oxide is 0.8%, the mass fraction of copper-based shape memory alloy is 3%, and the remaining The amount is 7 series aluminum alloy powder. The mass fraction of each element in the above 7 series aluminum alloy powder is Si: 3%, Fe: 0.6%, Cu: 1%, Mn: 0.3%, Mg: 2.8%, Cr: 0.3%, Zn: 6.4%, Ti: 0.3 %, Zr: 1.1%, Sc: 0.6%, and the balance is Al.

[0028] The preparation method of the above-mentioned 7-series aluminum alloy without cracks comprises the following steps:

[0029] S1. Gas atomization treatment at 700°C and 7MPa for 1h to prepare 7-series aluminum alloy powder, and gas atomization treatment at 1100°C and 8MPa for 1h to prepare copper-based shape memory alloy powder. Afterwards, the erbium oxide is dispersed in the aqueous solution, first the oxide suspension system is ultraso...

Embodiment 2

[0034] A 7-series aluminum-based composite material without cracks, comprising 7-series aluminum alloy powder, copper-based alloy powder, and erbium oxide powder, wherein the mass fraction of erbium oxide is 0.8%, the mass fraction of copper-based shape memory alloy is 3%, and the remaining The amount is 7 series aluminum alloy powder. The mass fraction of each element in the above 7 series aluminum alloy powder is Si: 3%, Fe: 0.6%, Cu: 1%, Mn: 0.3%, Mg: 2.8%, Cr: 0.3%, Zn: 6.4%, Ti: 0.3 %, Zr: 1.1%, Sc: 0.6%, and the balance is Al.

[0035] The preparation method of the above-mentioned 7-series aluminum alloy without cracks comprises the following steps:

[0036]S1. Gas atomization treatment at 700°C and 7MPa for 1h to prepare 7-series aluminum alloy powder, and gas atomization treatment at 1100°C and 8MPa for 1h to prepare copper-based shape memory alloy powder. Afterwards, erbium oxide is dispersed in the aqueous solution, the oxide suspension system is ultrasonically osc...

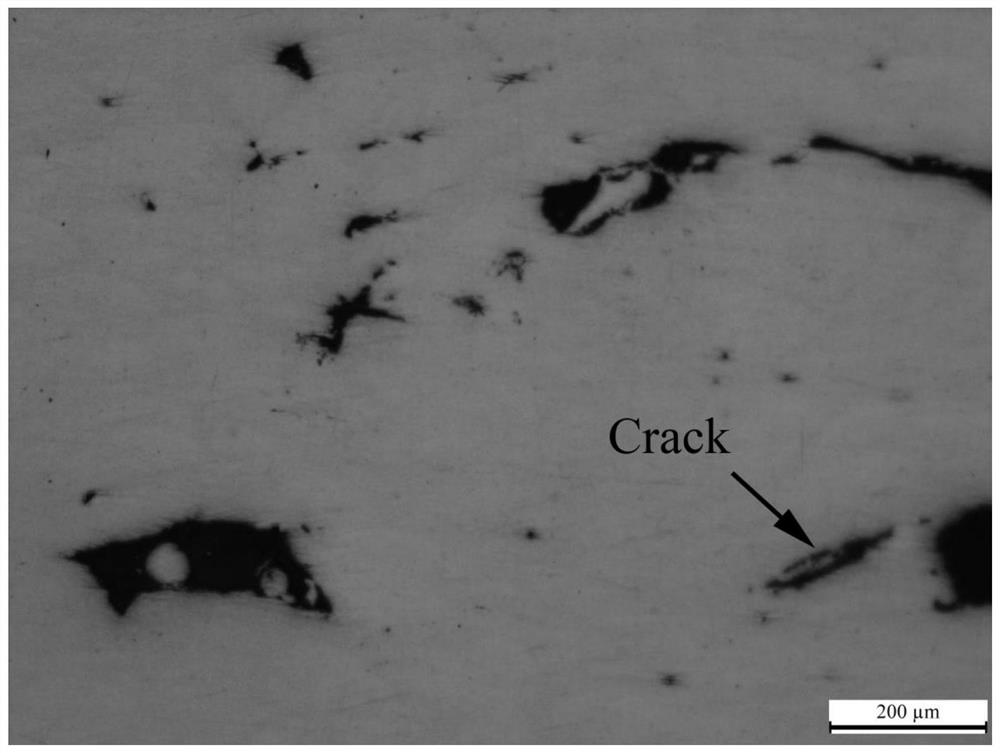

Embodiment 3

[0041] A 7-series aluminum-based composite material without cracks, comprising 7-series aluminum alloy powder, copper-based alloy powder, and erbium oxide powder, wherein the mass fraction of erbium oxide is 0.8%, and the mass fraction of 7-series aluminum alloy powder is 99.2%. The mass fraction of each element in the above 7 series aluminum alloy powder is Si: 3%, Fe: 0.6%, Cu: 1%, Mn: 0.3%, Mg: 2.8%, Cr: 0.3%, Zn: 6.4%, Ti: 0.3 %, Zr: 1.1%, Sc: 0.6%, and the balance is Al.

[0042] The preparation method of the above-mentioned 7-series aluminum alloy without cracks comprises the following steps:

[0043] S1. The 7-series aluminum alloy powder was prepared by gas atomization treatment at 700°C and 7MPa for 1 hour. Afterwards, erbium oxide is dispersed in the aqueous solution, the oxide suspension system is ultrasonically oscillated for 0.5 h, and a surfactant alkylsulfonate is added to the nano oxide suspension system under high-speed stirring. Then magnetically stir at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com