Patents

Literature

35 results about "Erbium(III) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Erbium(III) oxide, is synthesized from the lanthanide metal erbium. It was partially isolated by Carl Gustaf Mosander in 1843, and first obtained in pure form in 1905 by Georges Urbain and Charles James. It has a pink color with a cubic crystal structure. Under certain conditions erbium oxide can also have a hexagonal form. Erbium oxide is toxic when inhaled, taken orally, or injected into the blood stream in massive amounts. The effect of erbium oxides in low concentrations on humans over long periods of time has not been determined.

High-entropy ceramic material resistant to CMAS corrosion and preparation method and application thereof

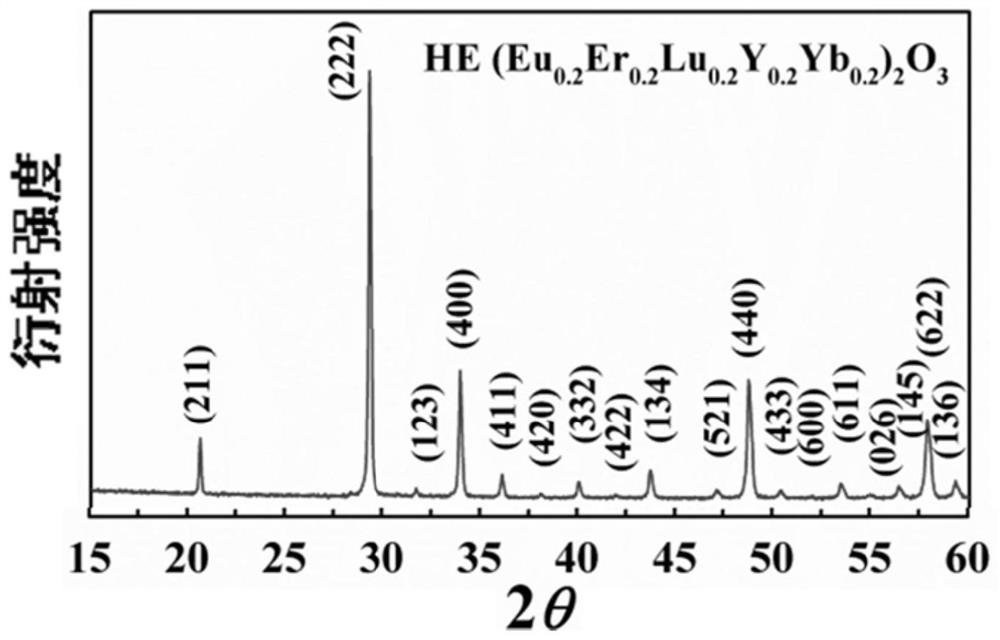

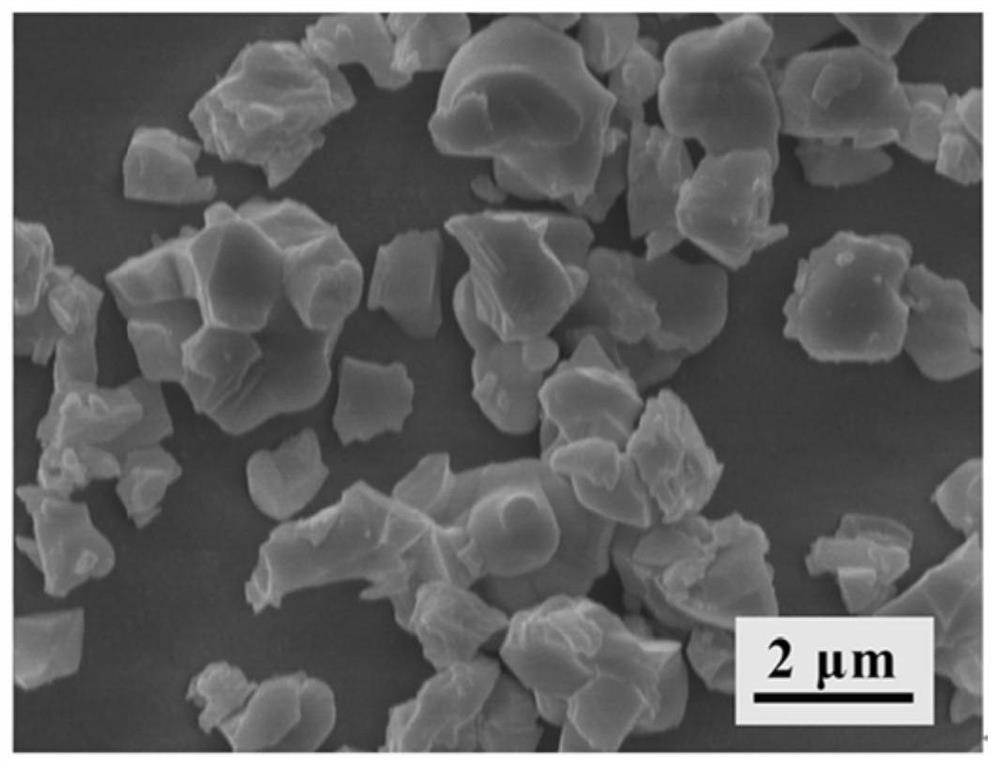

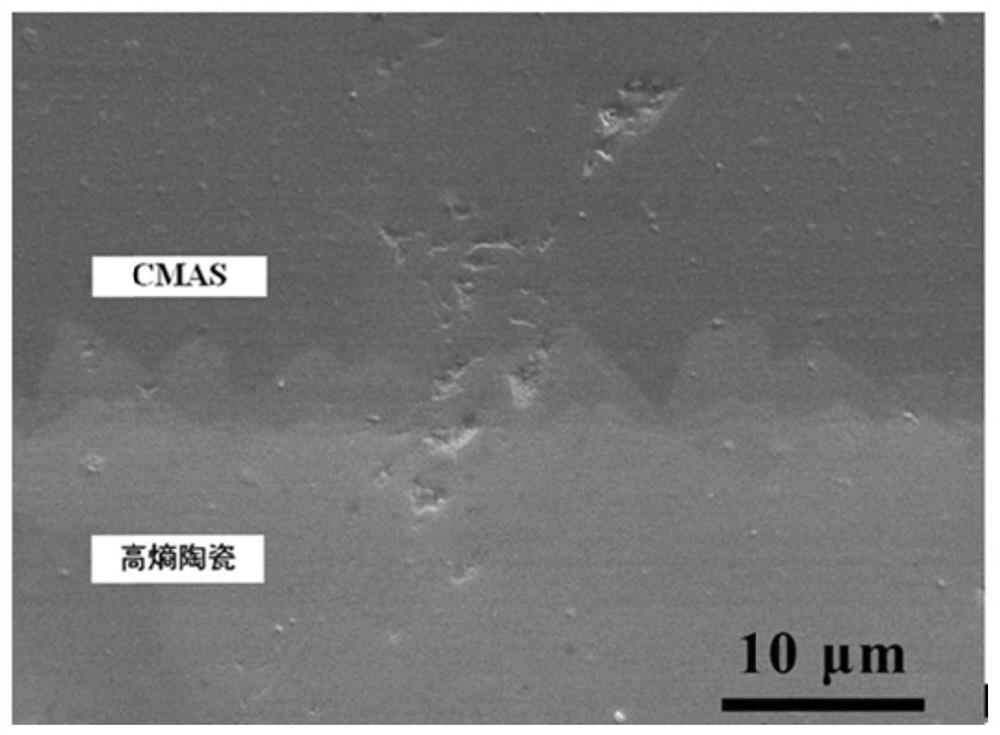

The invention provides a high-entropy ceramic material resistant to CMAS corrosion, a preparation method and an application thereof, the high-entropy ceramic material comprises the following raw materials: at least three of samarium oxide, europium oxide, erbium oxide and lutetium oxide, yttrium oxide and ytterbium oxide, and the amounts of substances of the raw materials are the same. The preparation method comprises the following steps: optionally selecting at least three of samarium oxide, europium oxide, erbium oxide and lutetium oxide, and conducting mixing with yttrium oxide and ytterbium oxide to obtain uniformly mixed slurry; and drying the slurry to obtain mixture powder, and carrying out pressureless calcination on the dried powder to obtain the high-entropy ceramic powder material. Analysis shows that the high-entropy ceramic powder material has the characteristics of high purity and strong CMAS corrosion resistance, the preparation method is simple and suitable for industrial production, and the high-entropy ceramic powder material has excellent application prospect in the field of thermal barrier coating materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

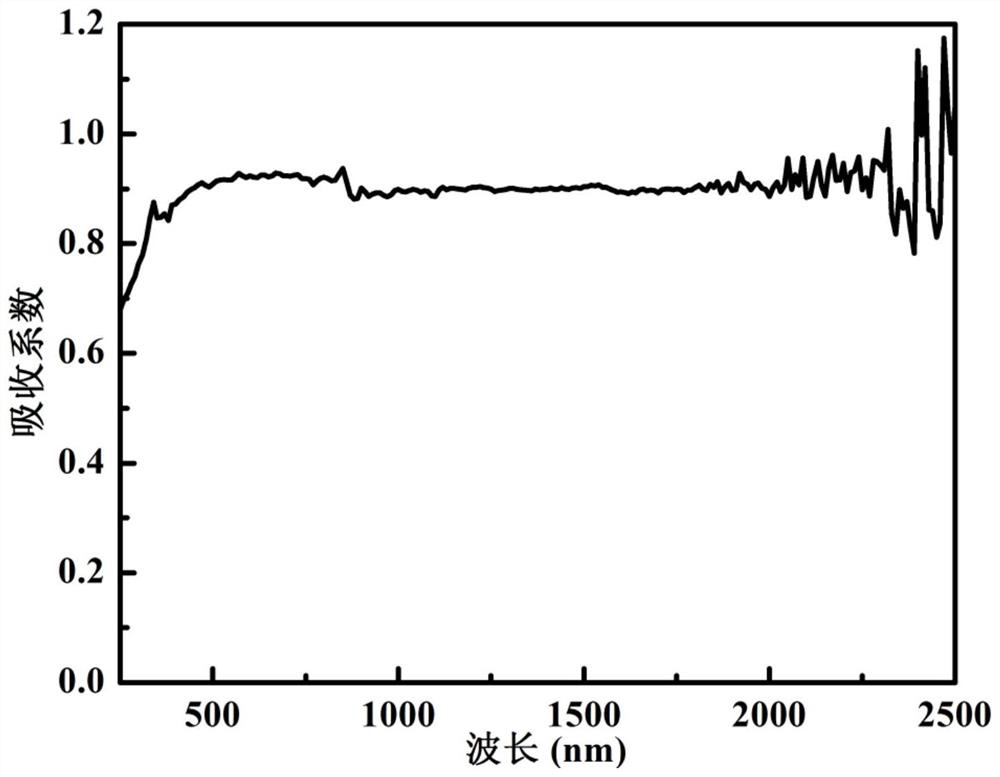

High-temperature-resistant near-infrared absorption high-entropy ceramic and preparation method thereof

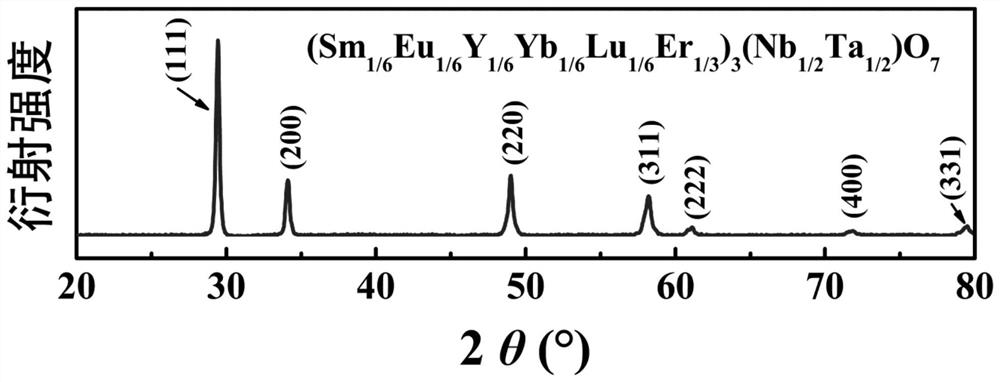

The invention relates to high-temperature-resistant near-infrared absorption high-entropy ceramic and a preparation method thereof. The high-entropy ceramic is prepared from the following raw materials in equal molar ratio: 1 part of yttrium oxide, 1 part of neodymium oxide, 1 part of samarium oxide, 1 part of europium oxide, 1 part of ytterbium oxide, 1 part of erbium oxide, 1 part of niobium oxide and 1 part of tantalum oxide. The purity of the high-temperature-resistant near-infrared absorption high-entropy ceramic is not lower than 99wt%, the relative density is not lower than 98%, and theabsorptivity of the high-temperature-resistant near-infrared absorption high-entropy ceramic in a near-infrared band of 0.25-2.5 microns is not lower than 0.9. The high-temperature-resistant near-infrared absorption high-entropy ceramic is obtained by utilizing a high-entropy technology, introducing not less than 6 rare earth metal elements into niobium tantalate at the same time and adjusting the absorption energy level of the forbidden band width to enable the forbidden band width to be matched with the near-infrared wavelength, and the technological process is simple, rapid, flexible and controllable.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

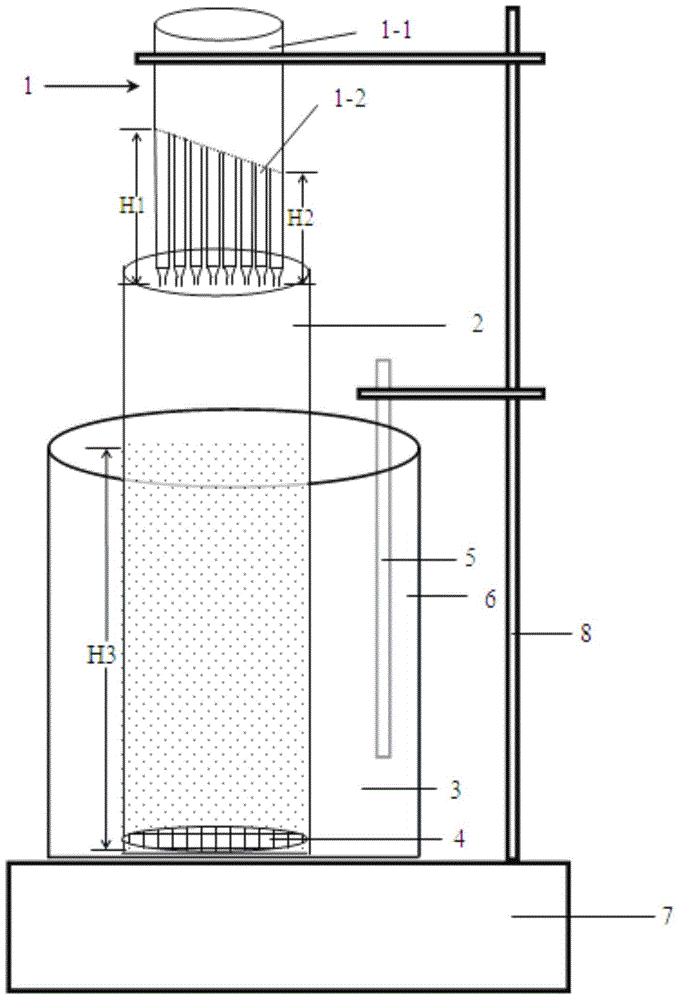

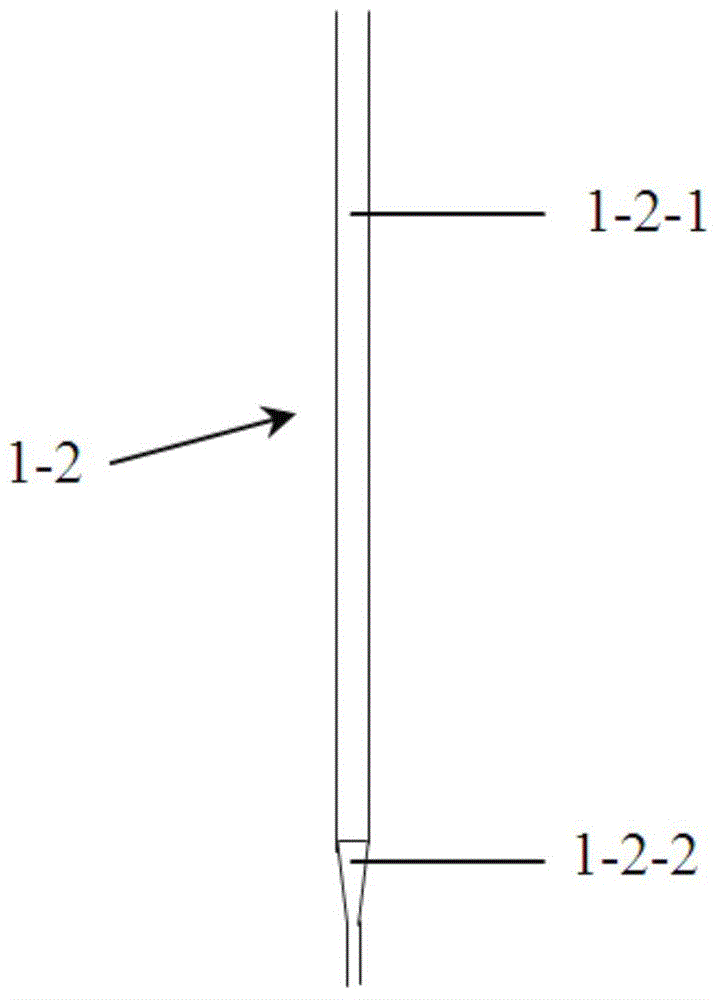

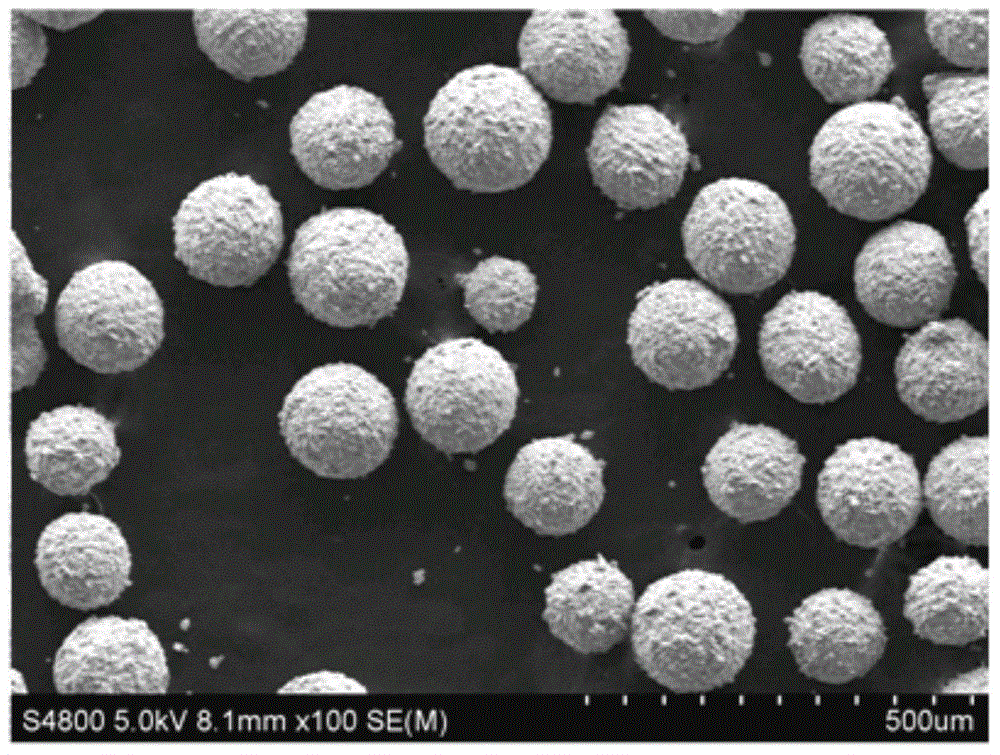

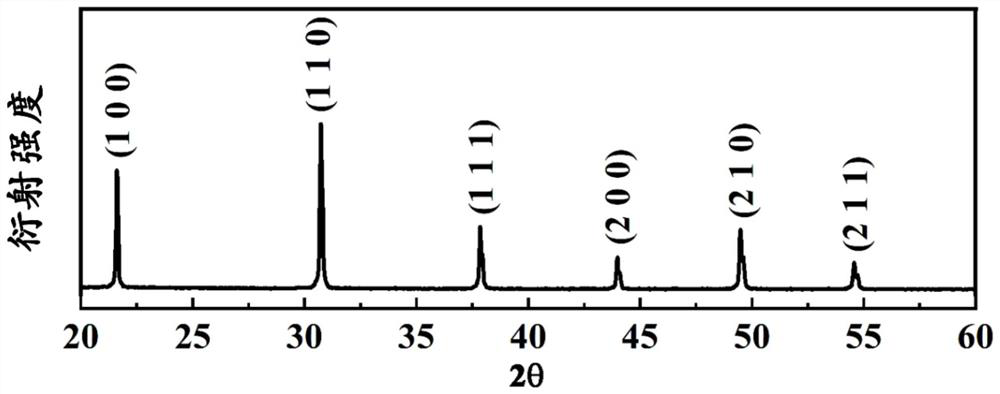

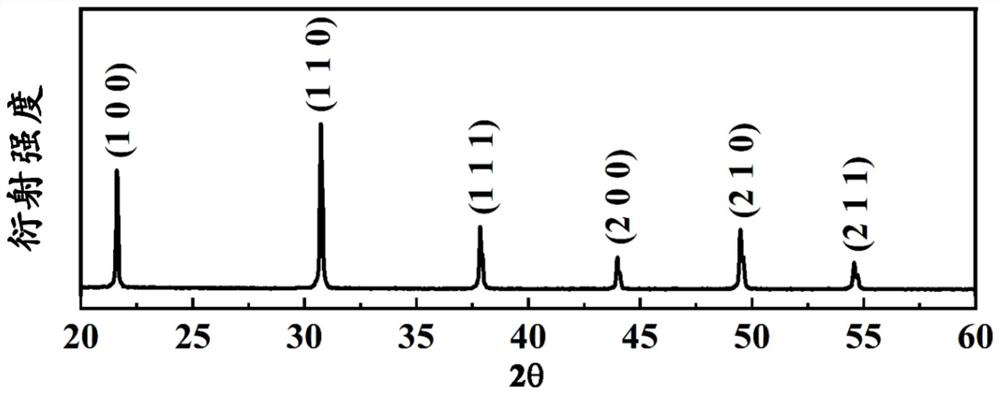

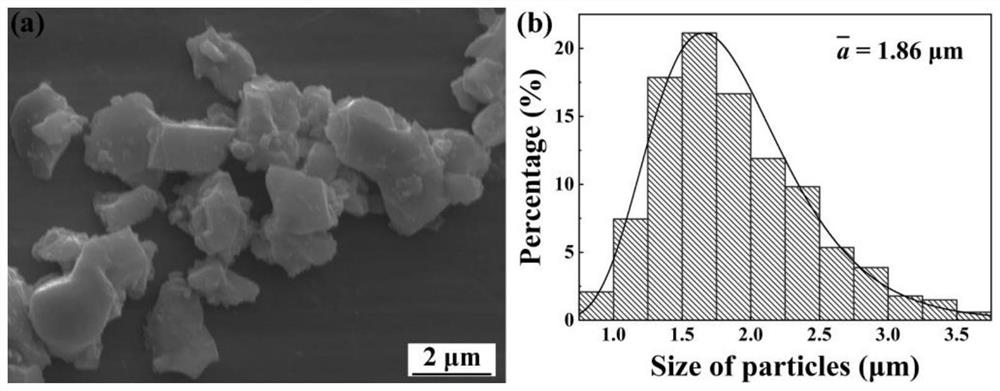

Micron-order high-density erbium oxide microsphere and preparation method thereof

InactiveCN103601231AGood sphericitySolve the problem of low densityRare earth metal compoundsEthylenediamineMicrosphere

The invention provides a micron-order high-density erbium oxide microsphere. The particle size of the microsphere is 50-150mu m, and the density of the microsphere is more than or equal to 88 percent of theoretical density of erbium oxide powder. A preparation method of the micron-order high-density erbium oxide microsphere comprises the following steps: 1, performing ball-milling on a premixed solution and the erbium oxide powder until the erbium oxide powder is uniformly dispersed in the premixed solution, and adding an aqueous solution of ammonium persulfate, thus obtaining slurry of which the solid-phase content is 50-60 percent; 2, (1) uniformly mixing tween80 and an oil phase to form a first mixed solution, adding the slurry into the first mixed solution, and stirring to obtain an emulsion; (2) uniformly mixing tetramethyl ethylenediamine, span80 and an oil phase to form a second mixed solution, and adding the emulsion into the second mixed solution through a burette; and (3) cleaning the cured microsphere obtained in the step (2), and drying to obtain an erbium oxide microsphere biscuit; and 3, batching the erbium oxide microsphere biscuit, and keeping the temperature to be 1890-1910 DEG C for 170-190 minutes under inert gas shielding, thus obtaining the micron-order high-density erbium oxide microsphere.

Owner:SICHUAN UNIV

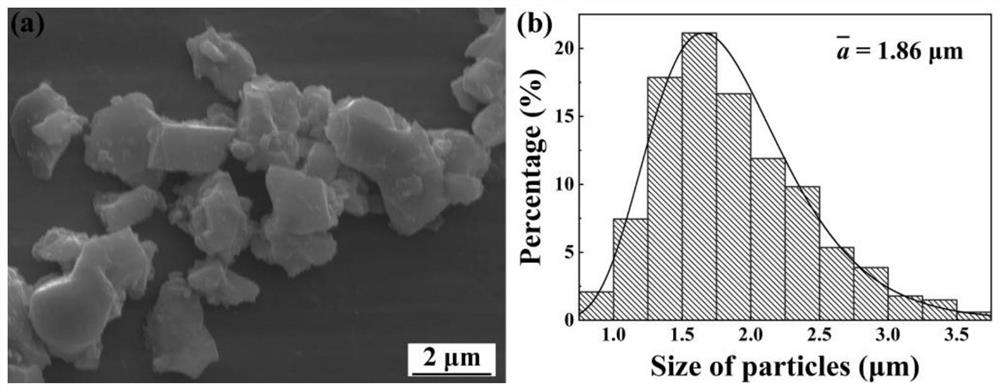

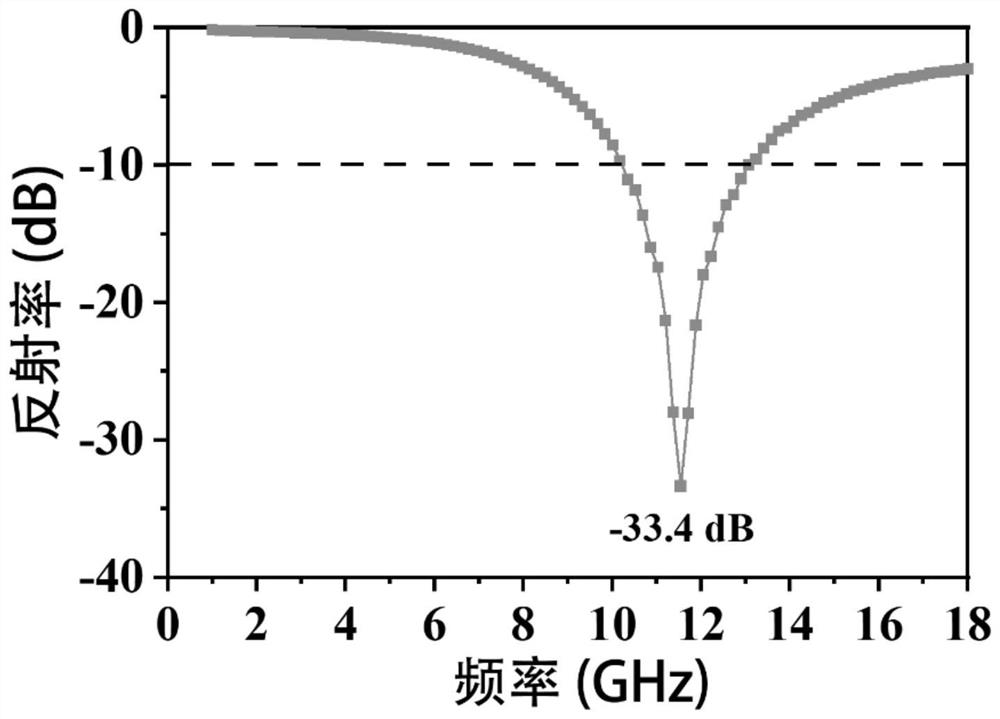

High-temperature-resistant high-entropy wave-absorbing ceramic as well as preparation method and application thereof

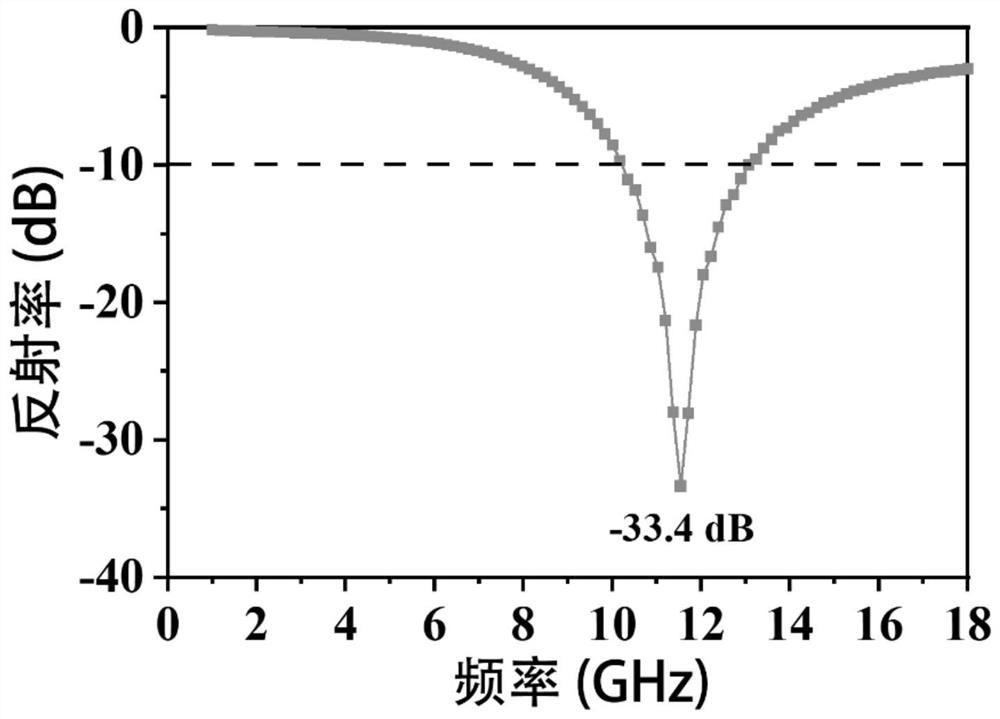

The invention relates to high-temperature-resistant high-entropy wave-absorbing ceramic as well as a preparation method and application thereof. The high-entropy ceramic is prepared from the followingraw materials in parts by mole: 0.98-1.02 parts of cerium oxide, 0.98-1.02 parts of yttrium oxide, 0.98-1.02 parts of samarium oxide, 0.98-1.02 parts of erbium oxide, 0.98-1.02 parts of ytterbium oxide and 15 parts of boron carbide. The high-entropy ceramic has the advantages of low density, high purity, strong wave absorption performance and wide absorption frequency band, the maximum wave absorption loss is 28-34dB, and the maximum absorption frequency band width is 3.5-3.9 GHz. The high-temperature-resistant high-entropy wave-absorbing ceramic is obtained through a high-temperature electric furnace under the vacuum condition by utilizing a high-entropy technology and introducing not less than 5 rare earth metal elements into hexaboride at the same time, and due to the influence of thehigh-entropy effect, the high-temperature stability of a reaction product is better, so that the required reaction conditions are lower, the process is simple and rapid, the practicability is high, and the ceramic is suitable for industrial production and has a good application prospect in the field of wave-absorbing materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

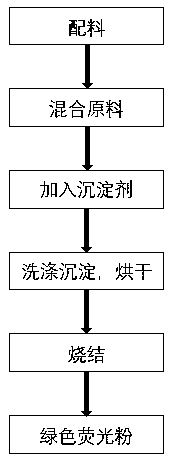

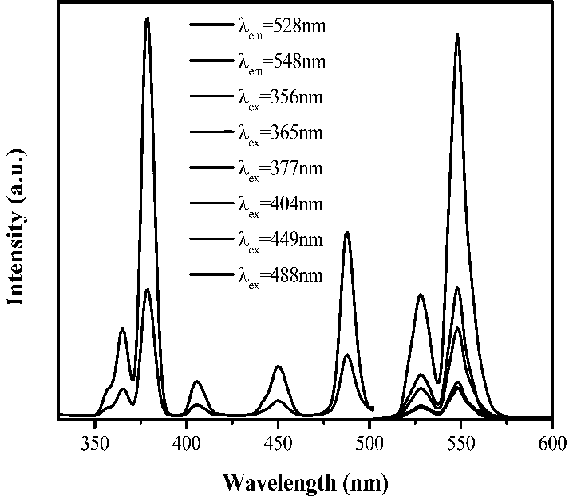

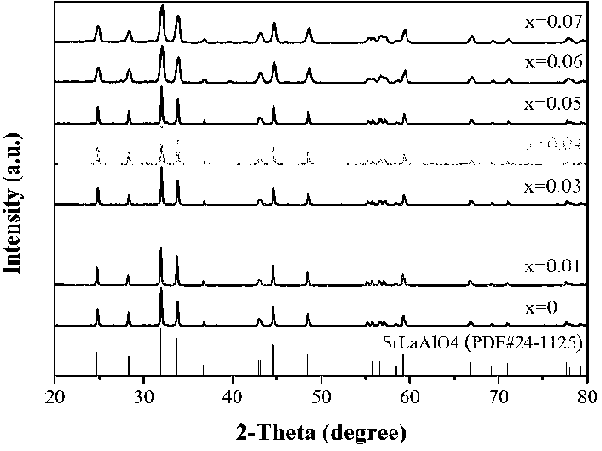

Near-ultraviolet excited green phosphor for non-contact temperature detector

ActiveCN110746969ARich excitation spectrumStrong absorption capacityThermometers using physical/chemical changesLuminescent compositionsUltravioletLanthanum

The invention discloses near-ultraviolet excited green phosphor for a non-contact temperature detector and a preparation method of the near-ultraviolet excited green phosphor, and belongs to the technical field of rare earth light emitting materials. The chemical formula of the near-ultraviolet excited green phosphor is SrLa(1-x)ErxAlO4, wherein x is larger than or equal to 0.01 and smaller than or equal to 0.07. A precursor is synthesized by a chemical coprecipitation method with stronium salt, lanthanum, aluminum-containing compound and erbium oxide as raw materials and ammonium carbonate, ammonium oxalate and ammonium bicarbonate as precipitants, a target product is prepared in combination with a primary calcination process, the phosphor has higher absorption at 350-370 nm, 370-390 nm and 475-490 nm, has emitting spectrum peaks near 528 nm and 548 nm respectively, has relation between corresponding fluorescence intensity ratio of two emission bands and temperature change of phosphorfollowing fluorescence intensity ratio (FIR), has good light emitting performance in a range of 298-573 K and has sensitivity up to 1.42% K<-1>, and the near-ultraviolet excited green phosphor for the non-contact temperature detector has potentials.

Owner:SICHUAN UNIV

Preparation method for rare-earth erbium alloy and rare-earth erbium alloy

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

Method for Manufacturing High-Purity Erbium, High-Purity Erbium, Sputtering Target Composed of High-Purity Erbium, and Metal Gate Film having High-Purity Erbium as Main Component

InactiveUS20110300017A1Not easily refinedEfficiently provideVacuum evaporation coatingSputtering coatingRare-earth elementPhysical chemistry

Provided are a method for manufacturing high-purity erbium, wherein crude erbium oxide is mixed with reducing metal, erbium is reduced and distilled by heating the mixture in a vacuum, and the distillate is melted in an inert atmosphere to obtain high-purity erbium; and high-purity erbium, wherein the purity excluding rare-earth elements and gas components is 4 N or higher and the oxygen content is 200 wtppm or less. An object of this invention is to provide a method of highly purifying erbium, which has a high vapor pressure and is difficult to be refined in a molten metal state, as well as technology for efficiently and stably providing high-purity erbium obtained with the foregoing method, a sputtering target composed of high-purity erbium, and a metal gate film having high-purity erbium as a main component.

Owner:JX NIPPON MINING & METALS CO LTD

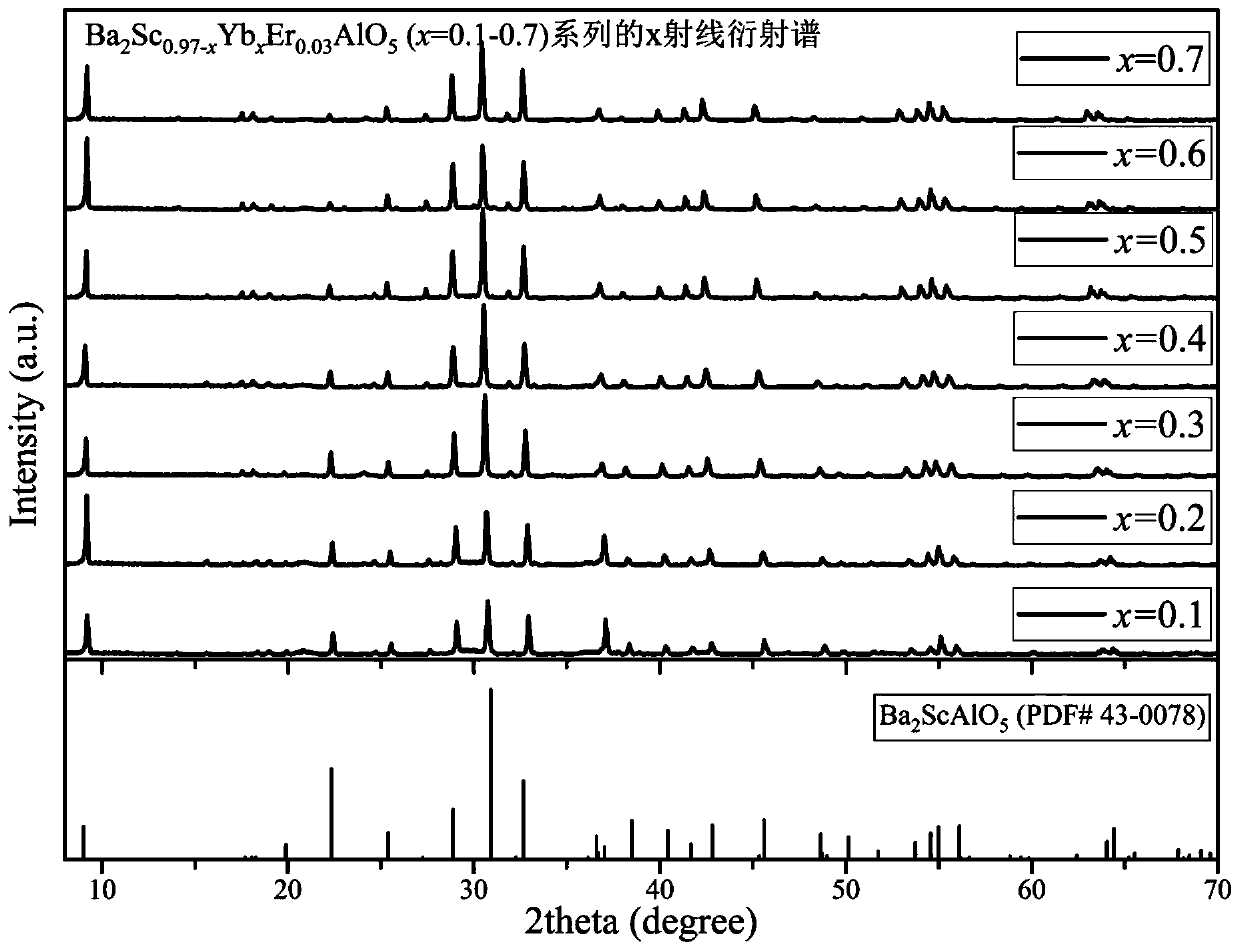

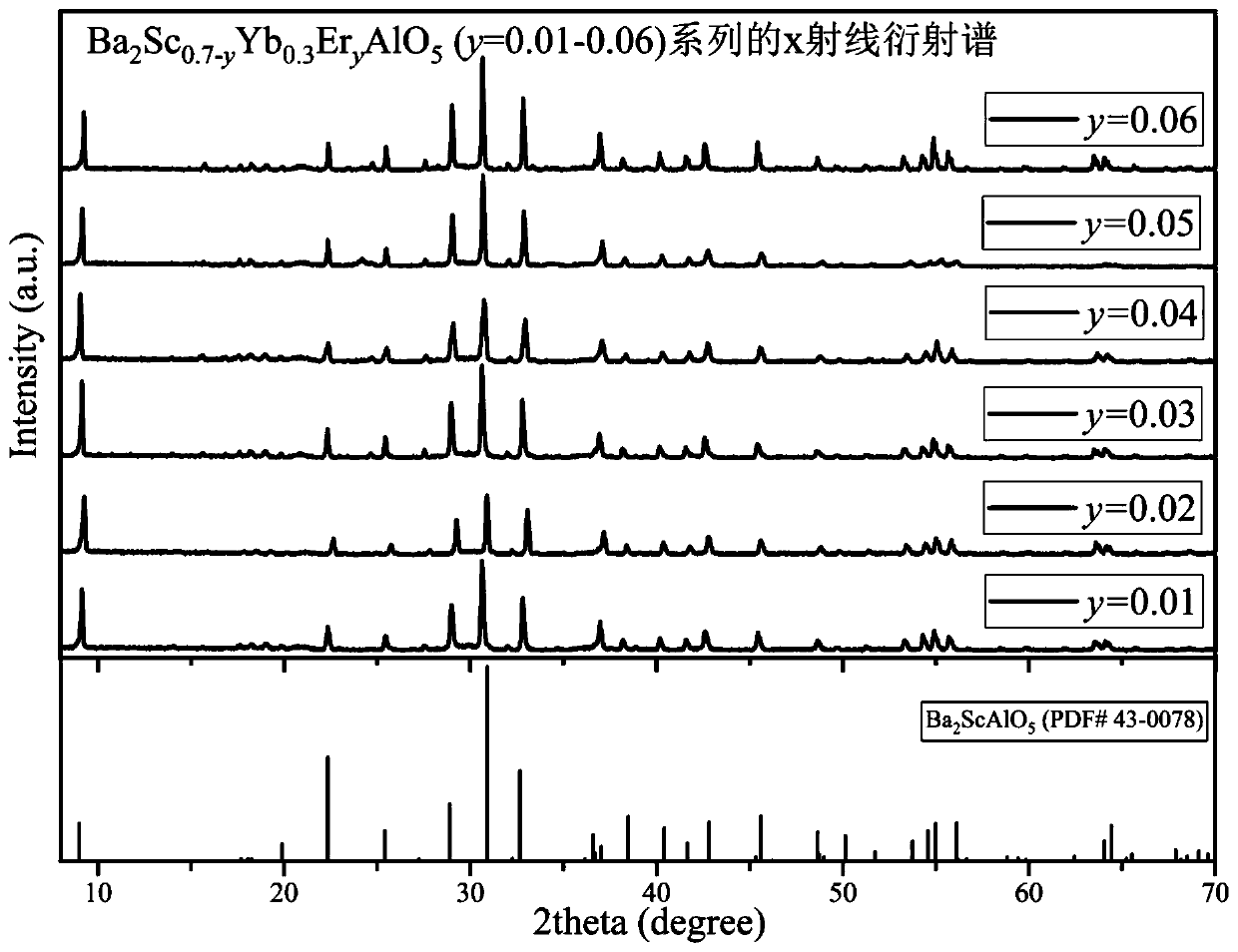

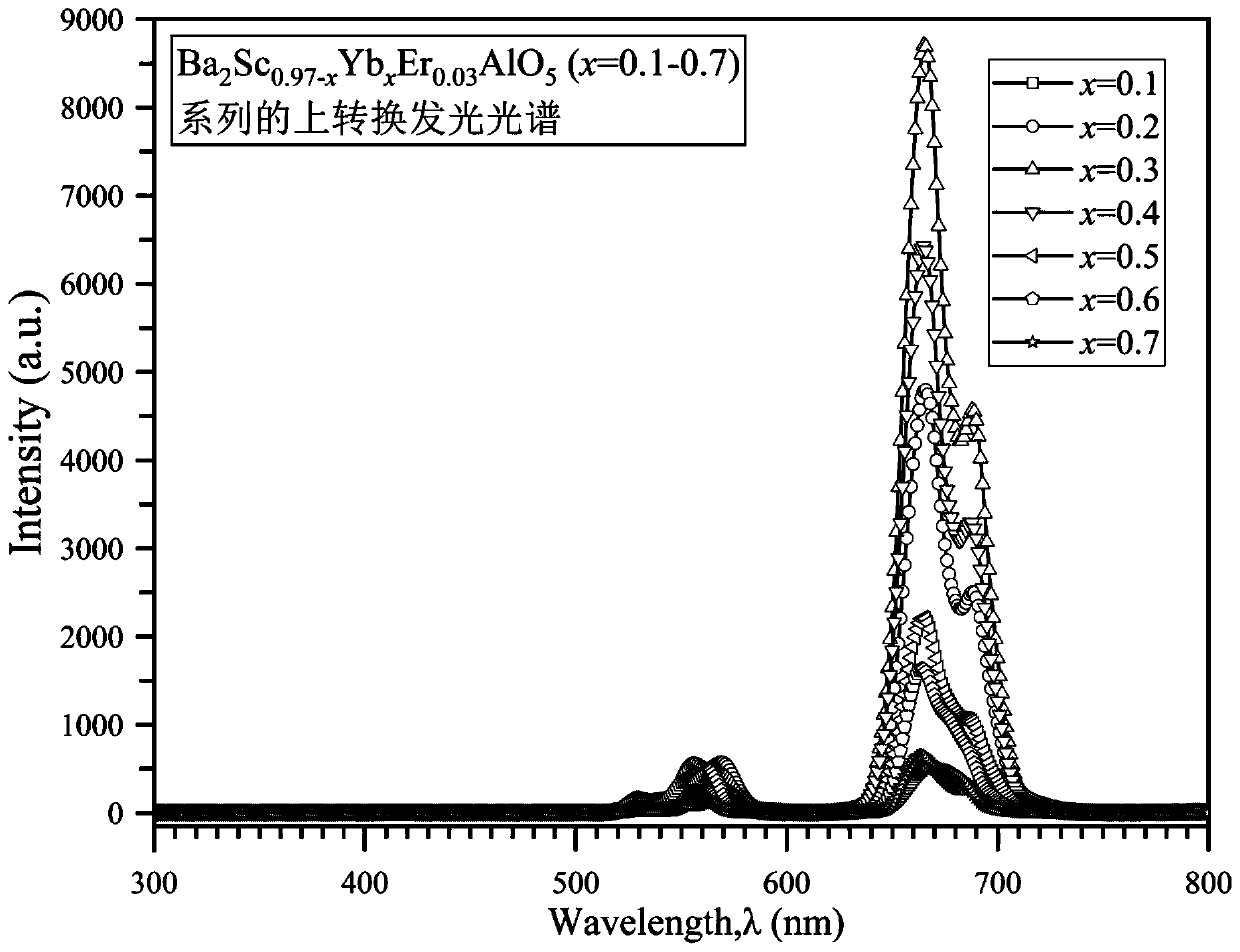

Rare earth doped scandium barium aluminate up-conversion luminescent material and preparation method thereof

ActiveCN110885684AGood repeatabilityImprove luminosityChemical industryLuminescent compositionsYTTERBIUM OXIDEAluminium hydroxide

The invention discloses a rare earth doped scandium barium aluminate up-conversion luminescent material and a preparation method thereof, and belongs to the technical field of luminescent materials. The up-conversion luminescent material provided by the invention has the structural formula of Ba2Sc(1-x-y)YbxEryAlO5, wherein x is equal to 0.1 to 0.6, and y is equal to 0.01 to 0.07. The preparationmethod is a high-temperature solid-phase method, and comprises the steps: by taking barium carbonate, scandium oxide, ytterbium oxide, erbium oxide and aluminum hydroxide as raw materials, uniformly mixing the raw materials by using absolute ethyl alcohol, drying, pressing into pieces, and carrying out high-temperature solid-phase sintering in a hydrogen furnace at the temperature of 1500 DEG C-1700 DEG C. The prepared rare earth doped scandium barium aluminate up-conversion luminescent material has excellent luminescent property, the highest relative luminescent intensity can reach 8701.14, the corresponding red light wavelength is 665 nm, and the luminescent intensity can be regulated and controlled by adjusting the proportion of doped rare earth. Meanwhile, the preparation method is good in repeatability, high in yield, simple and feasible in preparation process, more energy-saving and environment-friendly in preparation process and suitable for industrial popularization.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

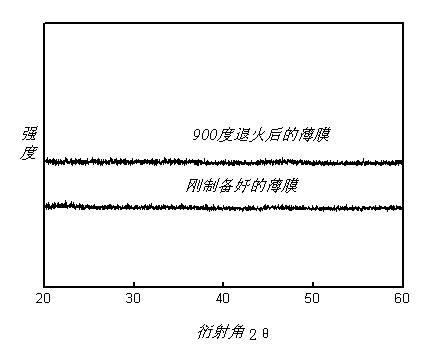

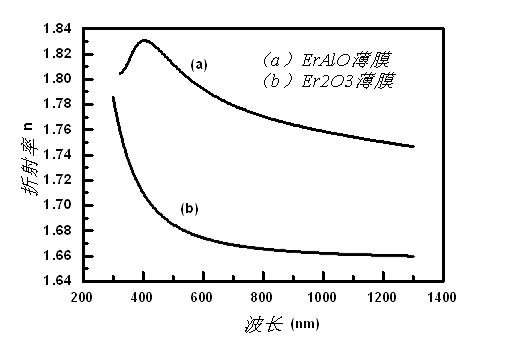

Antireflection material for solar cell and manufacturing method thereof

InactiveCN101997039AImprove thermal stabilityProper refractive indexSemiconductor devicesRadio frequency magnetron sputteringHeat stability

The invention discloses an antireflection material for a solar cell and a manufacturing method thereof. The antireflection material is an erbium oxide-aluminum oxide (Er2O3-Al2O3) composite material, wherein the content of Al2O3 is 20-30 percent. The antireflection material is a stable amorphous composite oxide material. In the invention, the antireflection material is manufactured by adopting radio frequency magnetron sputtering, and a sputtering target is an Er2O3 and Al2O3 mixed ceramic target; and an ErAlO amorphous antireflection oxide film is prepared on a P-type Si (100) substrate. The antireflection material for a solar cell has adjustable refractive index, good antireflection effect and good heat stability and optical characteristics.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

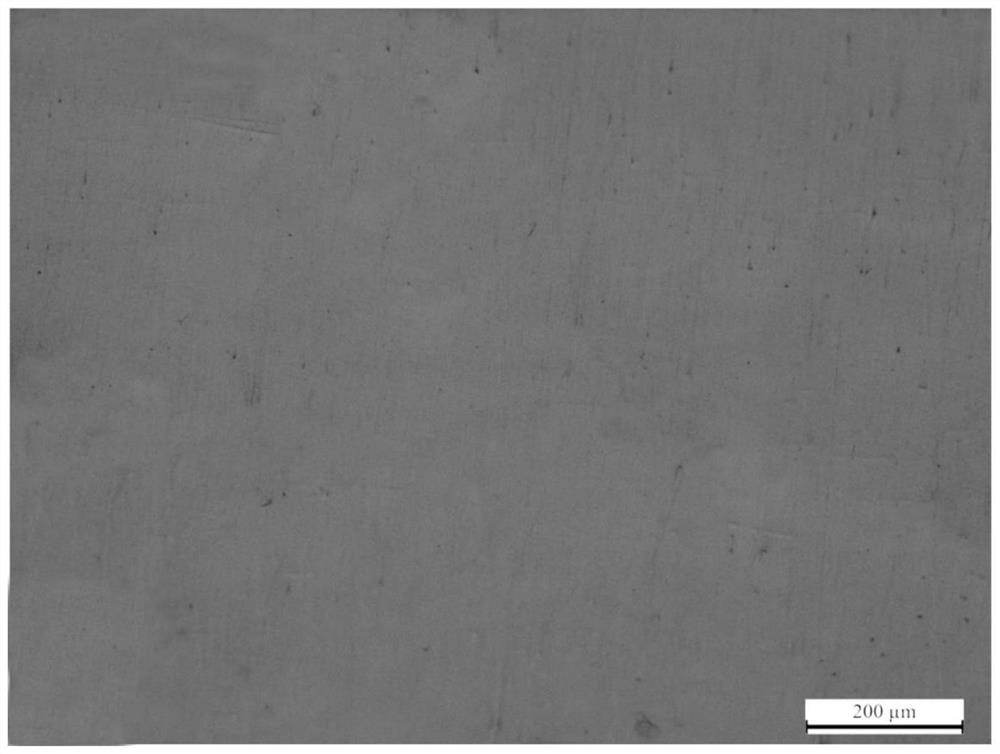

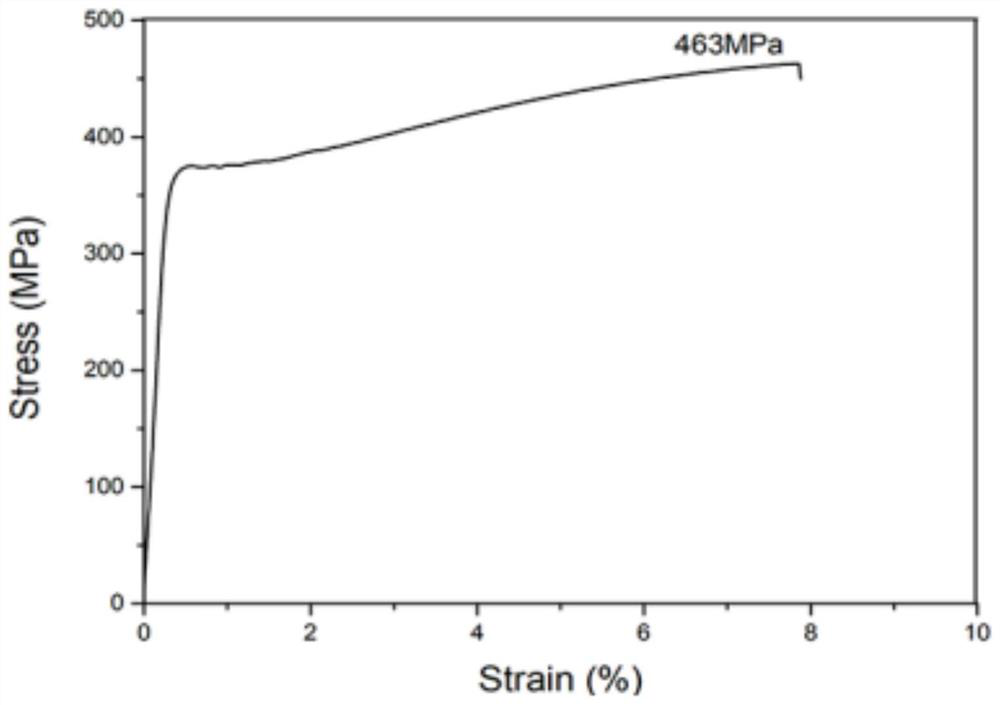

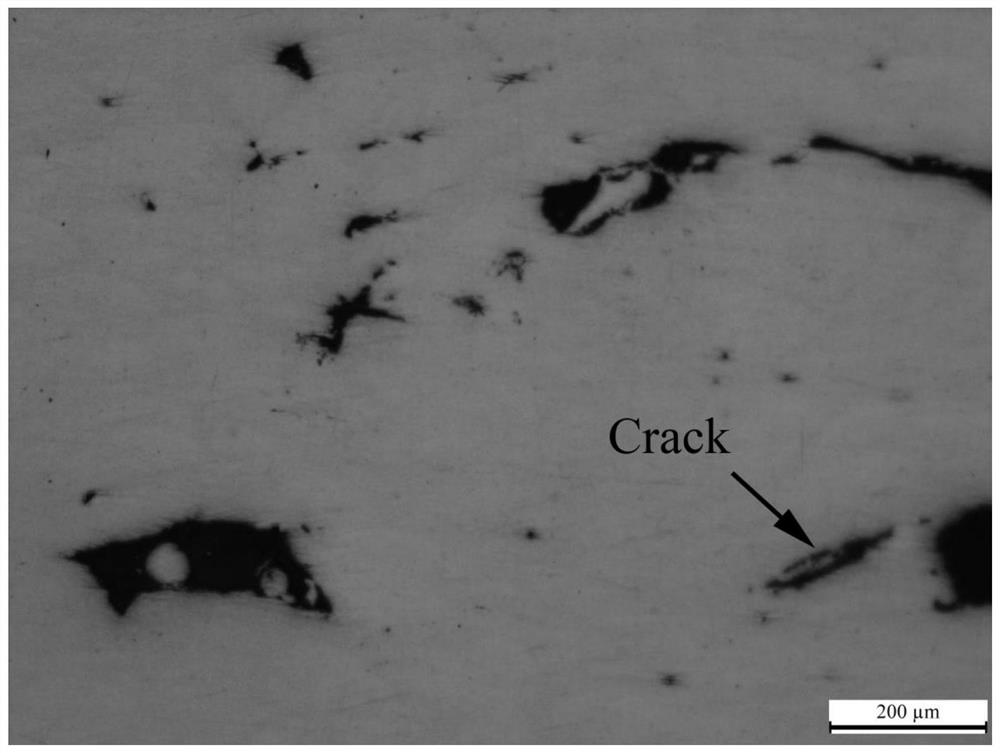

Special high strength 7-series aluminum-based composite material for 3D printing and preparation method thereof

ActiveCN111842890AEliminate cracksImprove mechanical propertiesAdditive manufacturing apparatusIncreasing energy efficiencyPowder bedShape-memory alloy

The invention discloses a special high strength 7-series aluminum-based composite material for 3D printing and a preparation method thereof. According to the preparation method of the special high strength 7-series aluminum-based composite material for 3D printing comprises, the special high strength 7-series aluminum-based composite material comprises 7-series aluminum alloy powder, copper-basedshape memory alloy powder and erbium oxide powder. The preparation method comprises the following steps of packaging the 7-series aluminum alloy powder, the copper-based shape memory alloy powder andthe erbium oxide powder in powder mixing equipment to be uniformly mixed; and drying and screening the mixed powder to obtain the 7-series aluminum-based composite powder for laser 3D printing of a powder bed, wherein the mixed powder comprises the following powder in percent by mass: 0.1-1% of erbium oxide powder, 0.1-3% of copper-based shape memory alloy powder and the balance of 7-series aluminum alloy powder. By adding the copper-based shape memory alloy and the erbium oxide, cracks of the 7-series aluminum alloy prepared by an SLM method are eliminated and the mechanical properties of the7-series aluminum alloy are improved.

Owner:CENT SOUTH UNIV

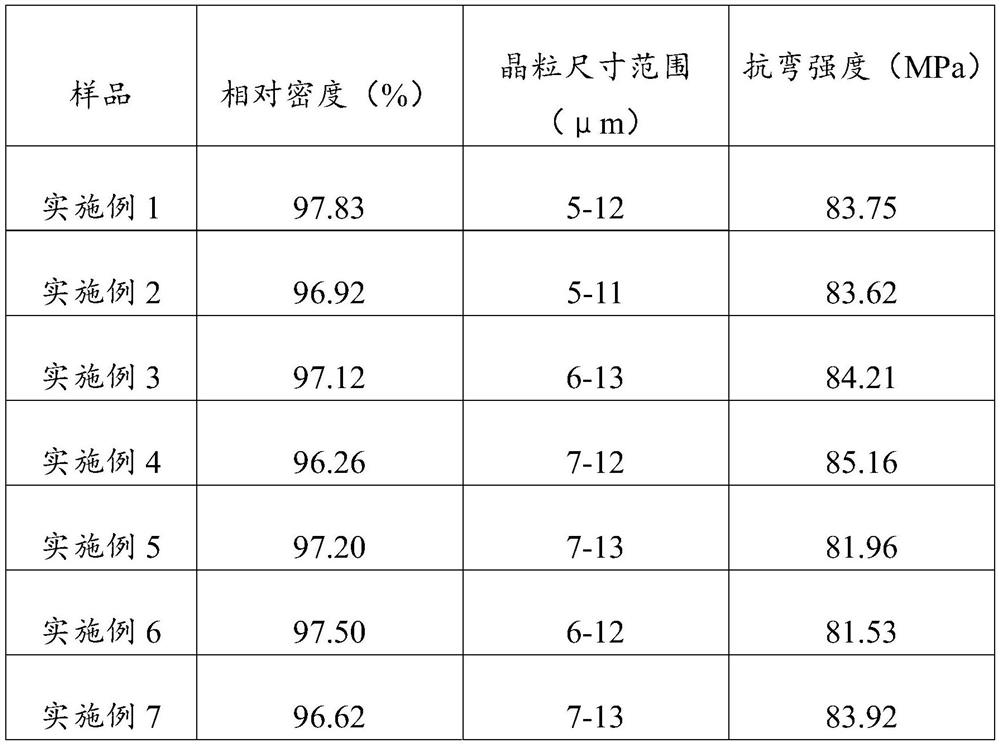

EITZO target material and preparation method thereof

PendingCN112266234ARefine the grain sizeImprove mobilityVacuum evaporation coatingSputtering coatingIndiumMaterials science

The invention provides an EITZO target material. The EITZO target material comprises a metal oxide composition, the EITZO target material comprises a metal oxide composition, and the metal oxide composition comprises indium oxide, tin oxide, erbium oxide and zinc oxide. The erbium oxide accounts for 5%-10% of the metal oxide composition. The preparation process of the EITZO target material comprises the following steps of pressing the metal oxide composition into a blank, molding and sintering. According to the EITZO target material, indium oxide, tin oxide, erbium oxide and zinc oxide are matched, and the EITZO target material is obtained through forming and sintering, so that the mobility of the EITZO target material after film coating is remarkably improved, the resolution ratio is improved, and the grain size of the EITZO target material is reduced. According to the EITZO target material disclosed by the invention, on the premise of controlling low cost, the mobility of the EITZO target material after film coating is improved, the resolution ratio is improved, the grain size of the EITZO target material is reduced, and the relative density of the EITZO target material is improved.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Ceramic material, method of production, layer and layer system

A ceramic material including at least erbium oxide (Er2O3)-stabilized zirconium oxide (ZrO2). The erbium oxide-stabilized zirconium oxide can be used as ceramic thermal barrier layer. Crack resistance of such ceramic materials is considerably increased by using erbium oxide-stabilized zirconium oxide.

Owner:SIEMENS AG

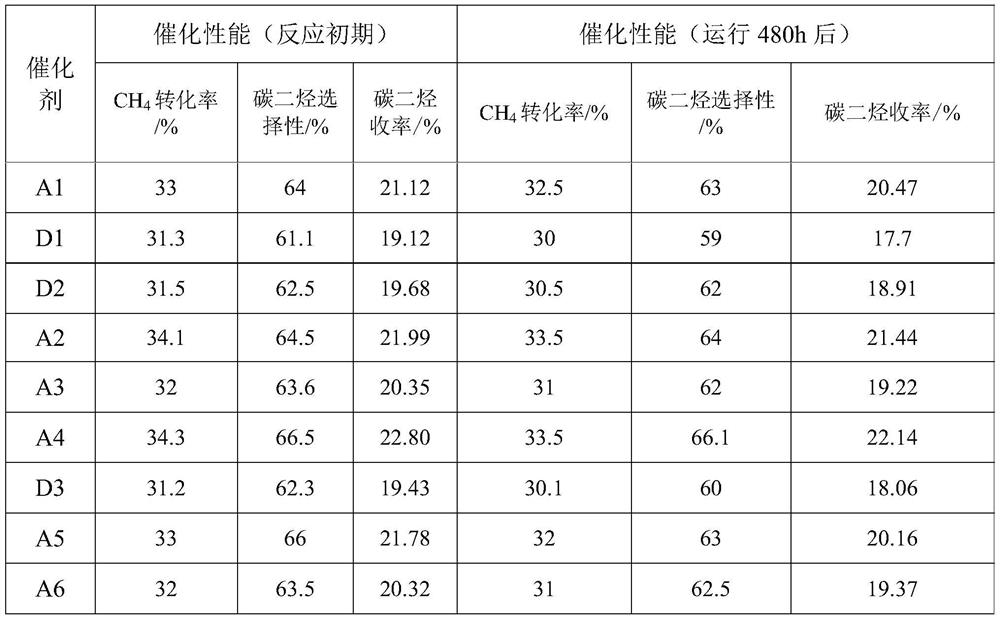

Methane oxidative coupling catalyst, preparation method thereof and method for preparing C2 hydrocarbon by oxidative coupling of methane

PendingCN112934216AThe preparation method is simple and easyImprove conversion rateHeterogenous catalyst chemical elementsHydrocarbon by hydrocarbon condensationPtru catalystPhysical chemistry

The invention relates to the field of comprehensive utilization of natural gas, and discloses a methane oxidative coupling catalyst, a preparation method thereof and a method for preparing C2 hydrocarbon by oxidative coupling of methane. The catalyst comprises cristobalite and an active component loaded on the cristobalite; the active component comprises sodium tungstate, erbium oxide and manganese oxide; and in the catalyst, based on the weight of cristobalite, the content of sodium tungstate is 1-15 wt%, the content of erbium oxide is 0.01-10 wt%, and the content of manganese oxide is 0.1-6.5 wt% in terms of manganese. The catalyst provided by the invention can promote the proceeding of methane coupling oxidation reaction, and improve the conversion rate of methane and the yields of ethylene and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of EIGZO target material

PendingCN112390622AImprove stabilityImprove photostabilityVacuum evaporation coatingSputtering coatingElectron orbitalIndium

The invention provides a preparation method of an EIGZO target material, and belongs to the field of target materials. According to the invention, indium oxide powder is used as a base material, and erbium oxide is added to regulate and control the carrier concentration in the semiconductor, so that the stability of the oxide semiconductor is improved, the doping amount of erbium ions is low, the5s electron orbit integrity of In can be ensured, and the advantage of high mobility is ensured, meanwhile, indium oxide, erbium oxide, gallium oxide and zinc oxide are compounded, so that the light stability of the oxide semiconductor is further improved, and besides, by adopting a mode of sintering without introducing oxygen and then introducing oxygen, the relative density of the obtained EIGZOtarget material is improved, and the oxide semiconductor is further ensured to have better mobility.

Owner:XIANDAO THIN FILM MATERIALS GUANGDONG CO LTD

Nanometer ceramic heat-insulating film and preparation method thereof

The invention relates to a nanometer ceramic heat-insulating film and a preparation method thereof, and belongs to the technical field of ceramic machining. The nanometer ceramic heat-insulating film comprises the following components in parts by weight: 5-8 parts of cerium oxide, 70-75 parts of silicon nitride, 6-10 parts of erbium oxide, 5-10 parts of alumina and 5-8 parts of titanium dioxide. The preparation method comprises the following steps: preparing a 20-25wt% emulsion by using the components in proportion, adding a certain amount of surface active agent, carrying out ultrasonic dispersion for 1-1.5 hours, and calcining for 2 to 3 hours at the temperature of 750-780 DEG C, thus obtaining no-hard aggregates, the particle size distribution of which is 15-20nm; then uniformly coating prepared nanometer ceramic powder on a base material, drying, and attaching a safety layer with impact resistance to the outer side of a thermal insulating layer, thus obtaining the nanometer ceramic heat-insulating film. The nanometer ceramic heat-insulating film has good chemical stability, scraping resistance, good heat resistance and the characteristics of simple preparation technology and relatively low cost, can be used for effectively prolonging the service life of a carrier and is suitable for popularization and application in industries.

Owner:GUANGZHOU VOCATIONAL COLLEGE OF SCI & TECH

Preparation method of magnesium-erbium-cerium fused fireproof profile

The invention discloses a preparation method of a magnesium-erbium-cerium fused fireproof profile, and relates to the technical field of fused fireproof profiles. The preparation method comprises following steps: weighing following raw materials: magnesia, erbium oxide, zirconia, and cerium oxide, wherein in the raw materials, magnesium accounts for 92.5 to 97 parts, erbium accounts for 1 to 3 parts, zirconium accounts for 0.5 to 1.5 parts, and cerium accounts for 1.5 to 3 parts; mixing and evenly stirring the raw materials in a mixing device; adding water, stirring to form a mixed material; drying the mixed material, adding the mixed material into an arc furnace at a time, fusing the mixed material, wherein during the fusion process, a microwave vibration mode is adopted, after the mixedmaterial is completely melted, taking out the electrodes, pouring the solution in the furnace into a profile grinding tool, and cooling. Cerium oxide and erbium oxide are added to improve the toughness and slag erosion resistant performance of the profile; one-time smelting and moulding is adopted, during the fusion process, a microwave vibration mode is adopted, the porosity of the profile is reduced, and the output and quality are both improved.

Owner:任有科

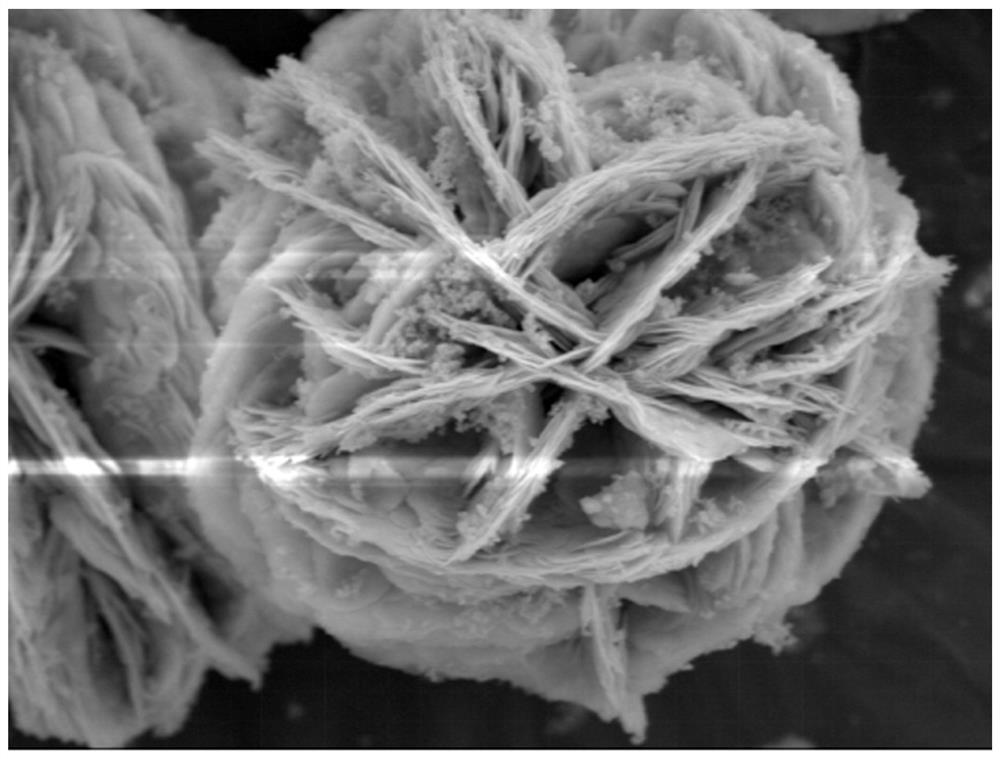

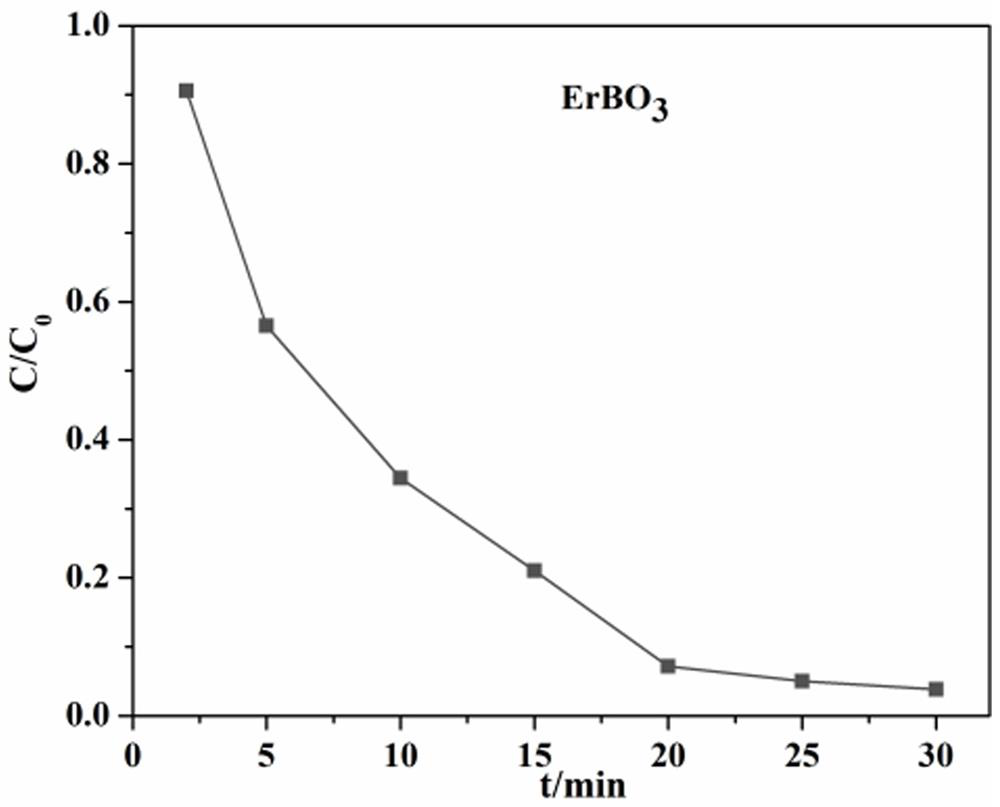

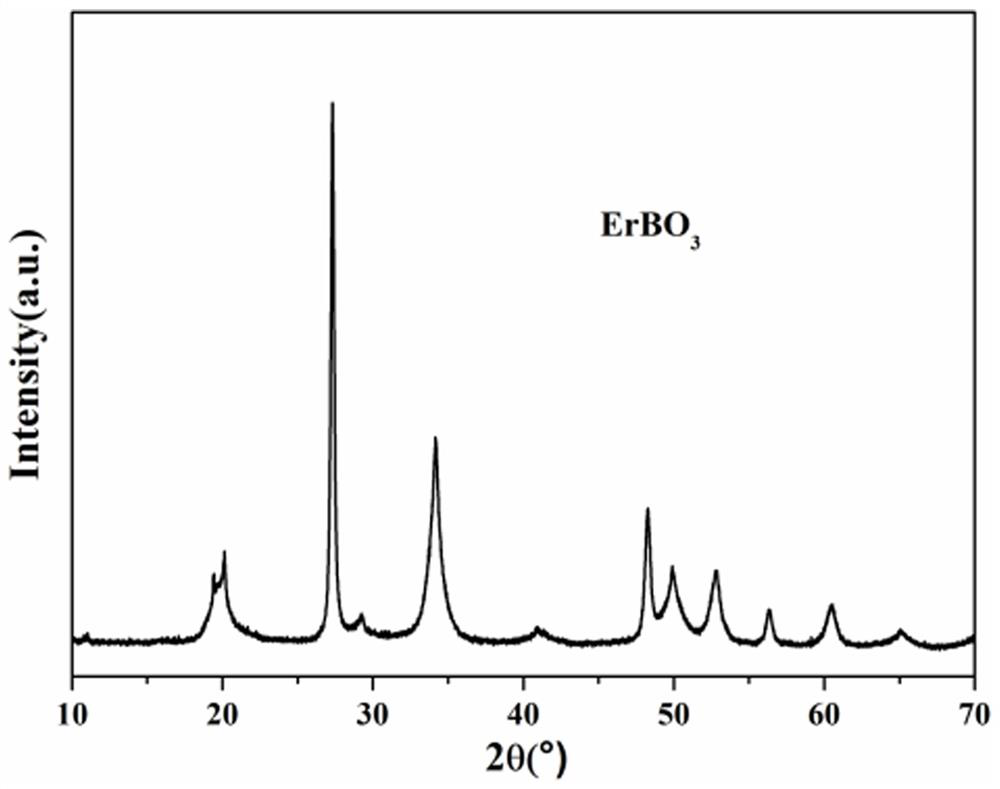

Preparation method of flower-ball-shaped ErBO3 photocatalyst composed of multiple lamellar petals

ActiveCN112473646AAdequate responseIntegrity guaranteedWater/sewage treatment by irradiationWater treatment compoundsPhysical chemistryPetal

Owner:TANGSHAN COLLEGE

A kind of dyeing agent and dyeing method for three-dimensional dyeing of zirconia ceramic crown

Owner:嘉兴饶稷科技有限公司

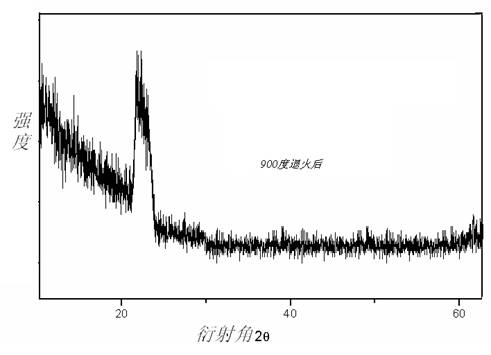

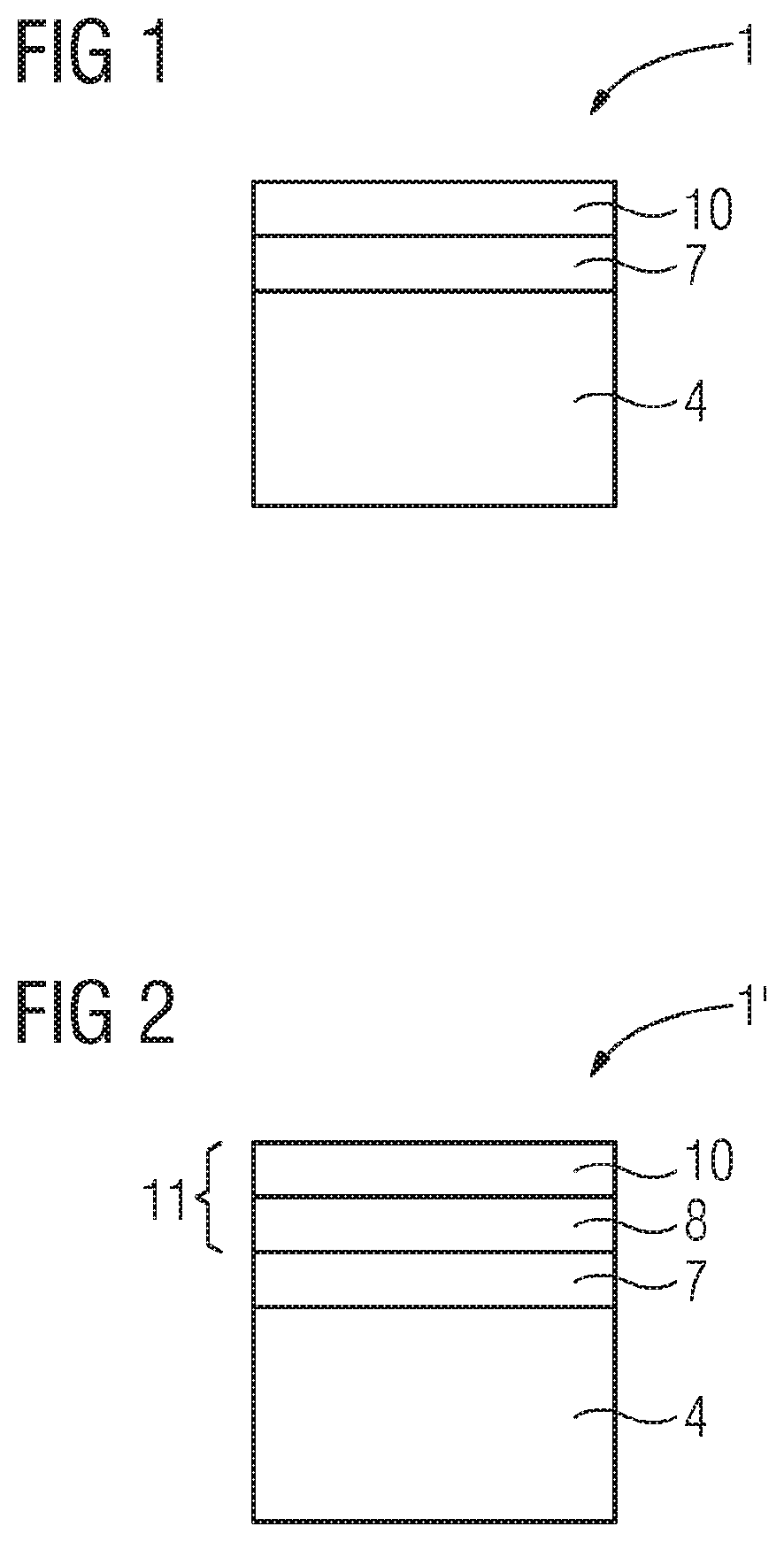

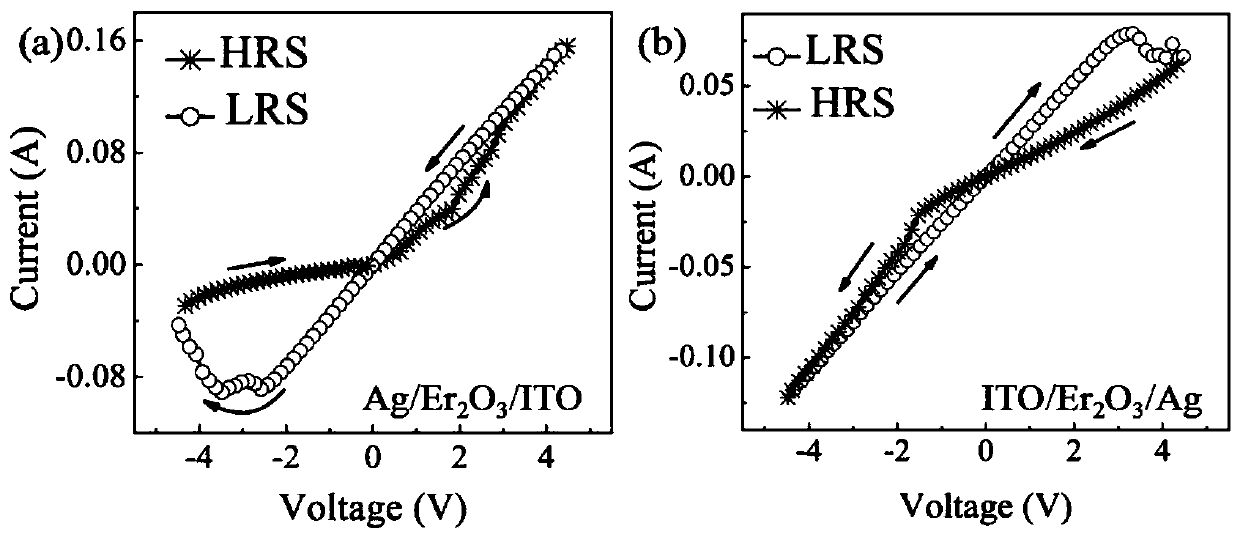

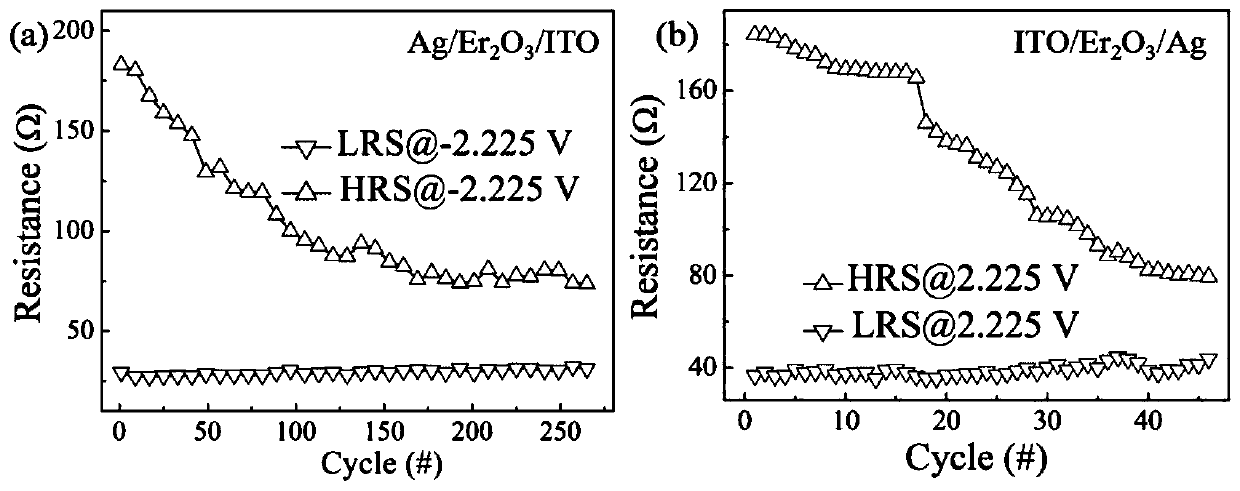

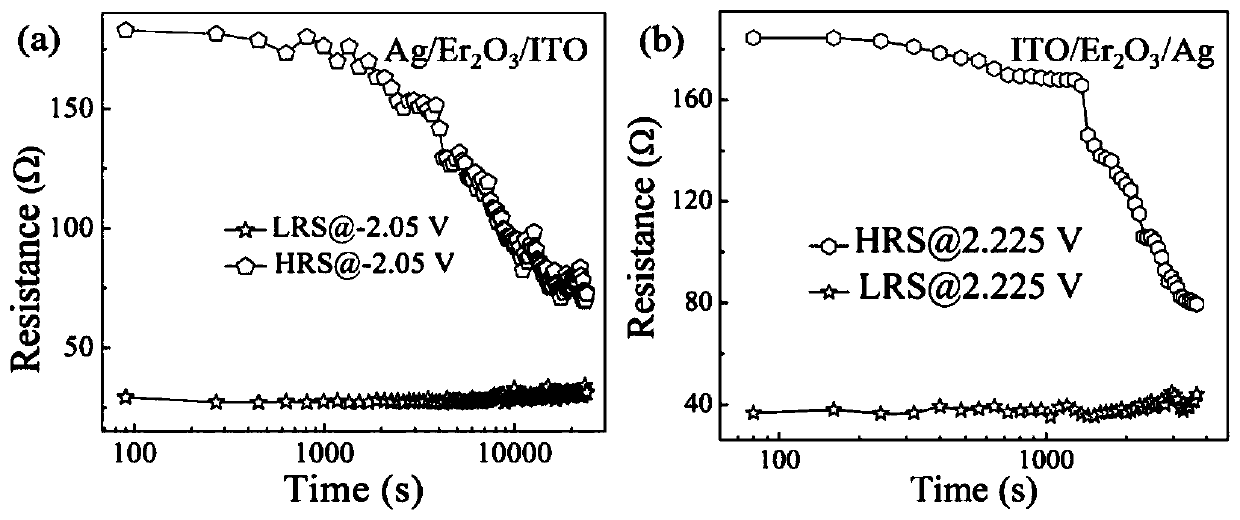

Memristor based on erbium oxide film and preparation method of memristor

ActiveCN109888090ASimple structureImprove performanceElectrical apparatusIndium tin oxideRadio frequency sputtering

The invention discloses a memristor based on an erbium oxide film and a preparation method of the memristor. The memristor comprises a top electrode, an erbium oxide film and a bottom electrode, wherein the erbium oxide film is located between the top electrode and the bottom electrode, wherein the top electrode and the bottom electrode are made of indium tin oxide or silver separately. The preparation method of the memristor based on the erbium oxide film comprises the following steps of S1, carrying out cleaning on a substrate; S2, adopting a magnetron sputtering method, taking indium tin oxide or a silver target is used as a sputtering source, and enabling the bottom electrode to be sputtered and deposited on the substrate; S3, adopting a radio frequency sputtering method, taking an erbium oxide target material as a sputtering source, and enabling a functional layer Er2O3 film to be deposited on the bottom electrode; and S4, adopting a direct current sputtering method, taking indiumtin oxide or silver target as a sputtering source, and enabling the upper electrode to be deposited on the surface of the erbium oxide film. The device is simple in structure, excellent in performance, stable, high in repeatability, simple in preparation method steps, and high in application prospect in the fields of novel memories, oscillators and other electronic devices.

Owner:SOUTHWEST JIAOTONG UNIV

Preparation method for erbium and neodymium doped nanometer silicon nitride composite ceramic

InactiveCN102775153AImprove compactnessImprove mechanical propertiesComposite ceramicPressureless sintering

The invention relates to the technical field of ceramic materials and specifically to a method for preparing a high performance silicon nitride (Si3N4) ceramic through pressureless sintering by using erbium oxide and neodymium oxide as additives. The ceramic comprises the following components expressed in mass percent: 3 to 7% of erbium oxide, 5 to 8% of neodymium oxide and 85 to 92% of silicon nitride. The objective of the invention is to provide the method for preparing the high performance silicon nitride ceramic through pressureless sintering by using erbium oxide and neodymium oxide as the additives to overcome disadvantages in the prior art, and the prepared ceramic can be extensively used for preparation of components and parts used in fields like the chemistry industry, machinery, metallurgy and the aerospace industry.

Owner:KUNSHAN ZHIJI MATERIAL TECH

Pressureless production process for erbium and lanthanum doped silicon nitride

The invention relates to the technical field of ceramic materials and specifically to a method for preparing a high performance silicon nitride (Si3N4) ceramic through pressureless sintering by using erbium oxide and lanthanum oxide as additives. The ceramic comprises the following components expressed in mass percent: 3 to 7% of erbium oxide, 5 to 8% of lanthanum oxide and 85 to 92% of silicon nitride. The objective of the invention is to provide the method for preparing the high performance silicon nitride ceramic through pressureless sintering by using erbium oxide and lanthanum oxide as the additives to overcome disadvantages in the prior art, and the prepared ceramic can be extensively used for preparation of components and parts used in fields like the chemistry industry, machinery, metallurgy and the aerospace industry.

Owner:KUNSHAN ZHIJI MATERIAL TECH

A kind of high temperature resistant and high entropy wave absorbing ceramic and its preparation method and application

The invention relates to a high-temperature-resistant high-entropy wave-absorbing ceramic and a preparation method and application thereof. The high-entropy ceramic is prepared from the following raw materials in molar ratio: 0.98-1.02 parts of cerium oxide, 0.98-1.02 parts of yttrium oxide, and 0.98 parts of samarium oxide -1.02 parts, erbium oxide 0.98-1.02 parts, ytterbium oxide 0.98-1.02 parts, boron carbide 15 parts. The high-entropy ceramic has the advantages of low density, high purity, strong absorption performance and wide absorption frequency band, the maximum absorption loss is 28-34dB, and the maximum absorption frequency bandwidth is 3.5-3.9GHz. The present invention utilizes high-entropy technology to simultaneously introduce no less than 5 kinds of rare earth metal elements into hexaborides, and obtains a high-temperature-resistant and high-entropy wave-absorbing ceramic through a high-temperature electric furnace under vacuum conditions. Due to the influence of the high-entropy effect, the reaction product The high temperature stability is better, so the required reaction conditions are lower, the process is simple, fast, and practical, suitable for industrial production, and has a good application prospect in the field of wave absorbing materials.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH

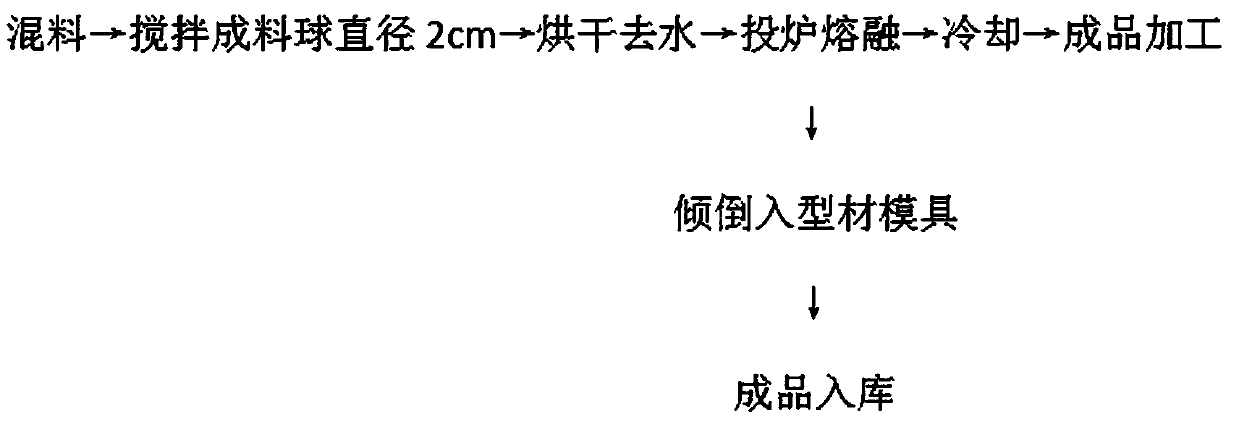

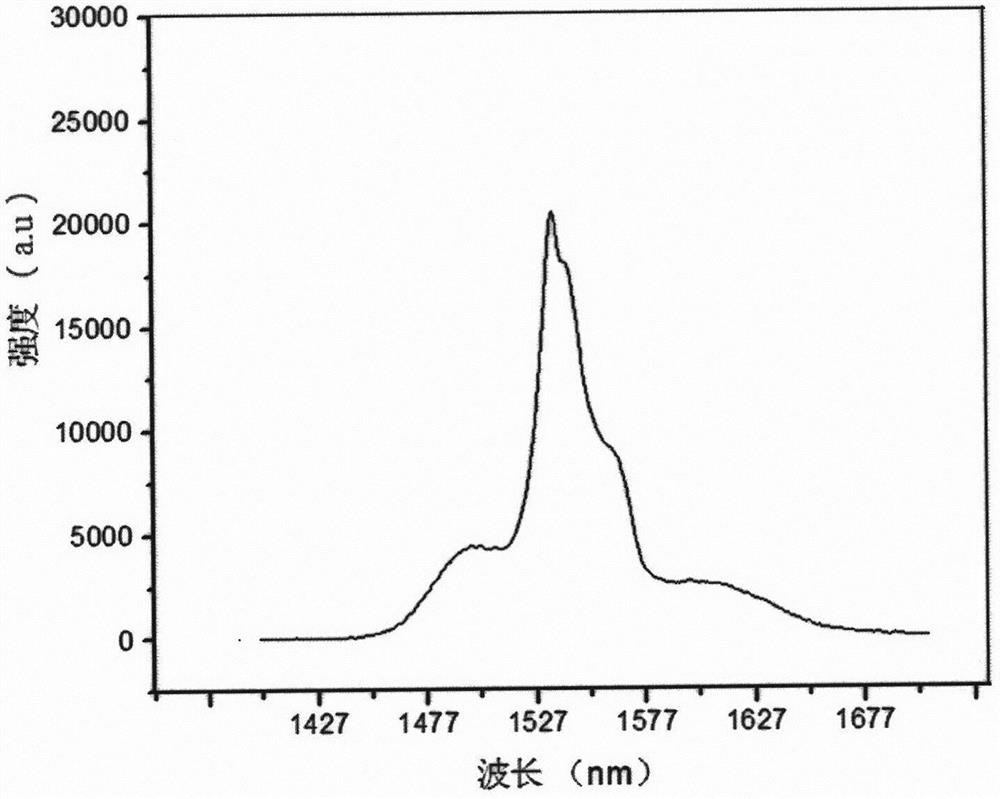

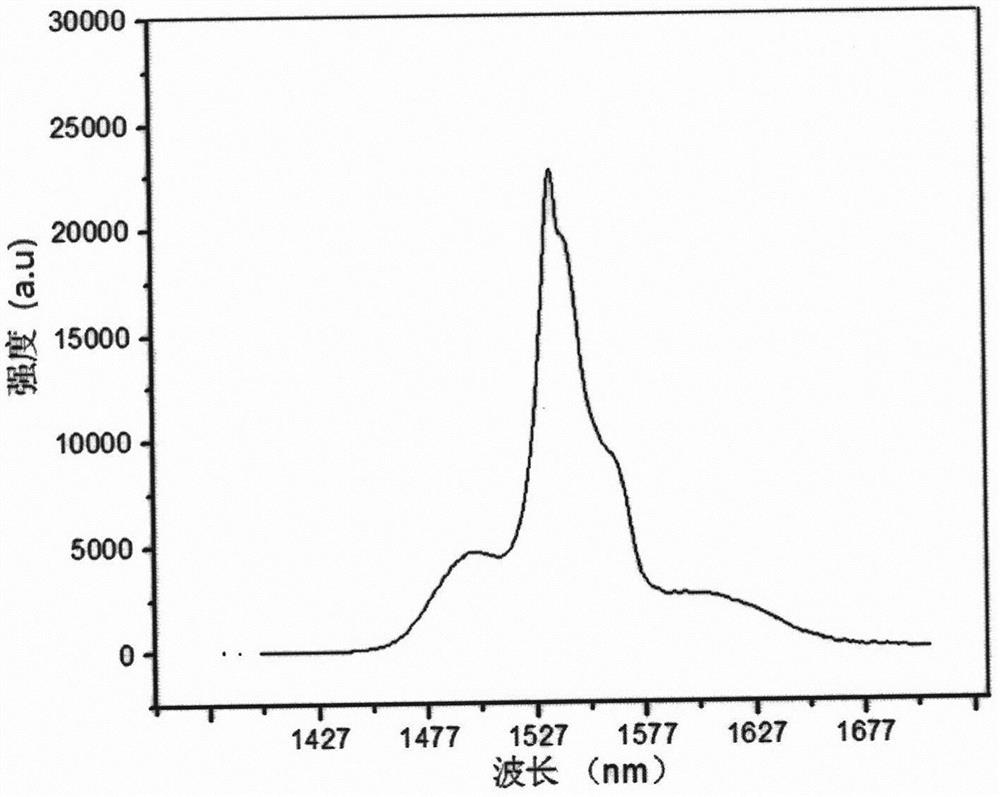

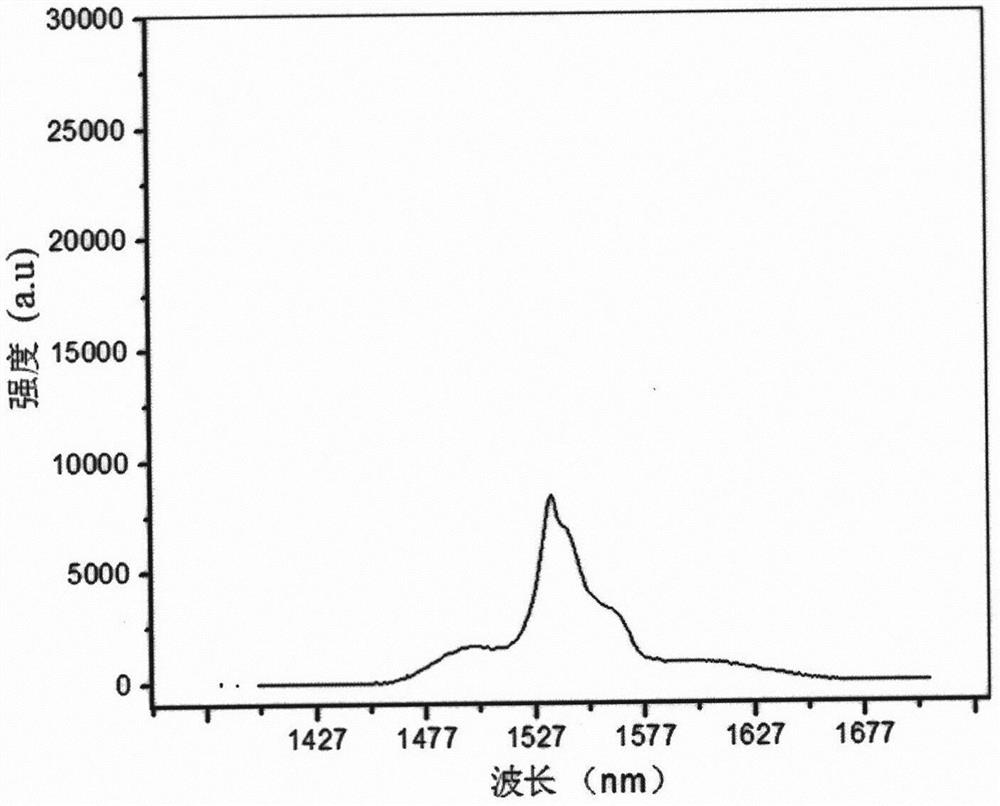

A kind of ytterbium-erbium co-doped phosphate glass and its preparation method and application

InactiveCN109354402BHigh glass forming abilityGood optical performanceActive medium materialActive medium shape and constructionP phosphatePhosphate glass

The invention belongs to the technical field of optical glass, and in particular relates to ytterbium-erbium co-doped phosphate glass and its preparation method and application. A kind of ytterbium-erbium co-doped phosphate glass, its composition ratio includes: 27-37 parts of phosphorus pentoxide; 17-29 parts of bismuth trioxide; 5-15 parts of antimony trioxide; 7-14 parts of calcium; 3-11 parts of aluminum oxide; 4-11 parts of diboron trioxide; 2-9 parts of tellurium dioxide; 0.1-1 part of erbium oxide. A method for preparing ytterbium-erbium co-doped phosphate glass, comprising: (1) batching; (2) mixing; (3) melting; (4) cooling and forming; (5) annealing; (6) processing. The ytterbium-erbium co-doped phosphate glass prepared by the above method is used to prepare fiber lasers and fiber amplifiers. The phosphate glass of the present invention has the advantages of good glass forming ability, excellent optical performance, small transmission loss and the like.

Owner:南京豪祺新材料有限公司

Preparation method of rare earth erbium-iron alloy and rare earth erbium-iron alloy

PendingCN114277406AEasy to separateReduce inclusionsElectrolysis componentsElectrolysisMass fraction

The invention relates to a preparation method of a rare earth erbium-iron alloy and the rare earth erbium-iron alloy. According to the method, a graphite crucible is used as an electrolytic bath; a graphite flake is an anode; a pure iron rod is used as a cathode; the iron crucible is a metal receiver; erbium oxide is used as a raw material; the method comprises the following steps of: electrolyzing at the temperature of between 1,090 and 1,110 DEG C with the current of between 4,000 and 4,500 A and the voltage of between 12 and 15 V by taking sodium hydroxide as a cathode, barium fluoride and sodium fluoride as a binary system electrolyte, and drying an electrolytic bath; adding a binary system electrolyte, melting to a certain degree, placing an iron crucible in the center of the furnace bottom, placing a pure iron rod above the iron crucible, and starting electrolysis; adding erbium oxide, and adjusting the purity of the iron rod in time; and after electrolyzing for a period of time, taking out the iron crucible, pouring into an ingot, cooling and demolding to obtain the erbium-iron alloy. In the prepared rare earth erbium-iron alloy, the mass fraction of iron is 15.1%-18.2%, and the mass fraction of erbium is 81.3%-84.4%; the method is low in energy consumption, high in productivity, small in deviation and convenient for large-scale production.

Owner:赣州市天成稀土新材料工贸有限公司

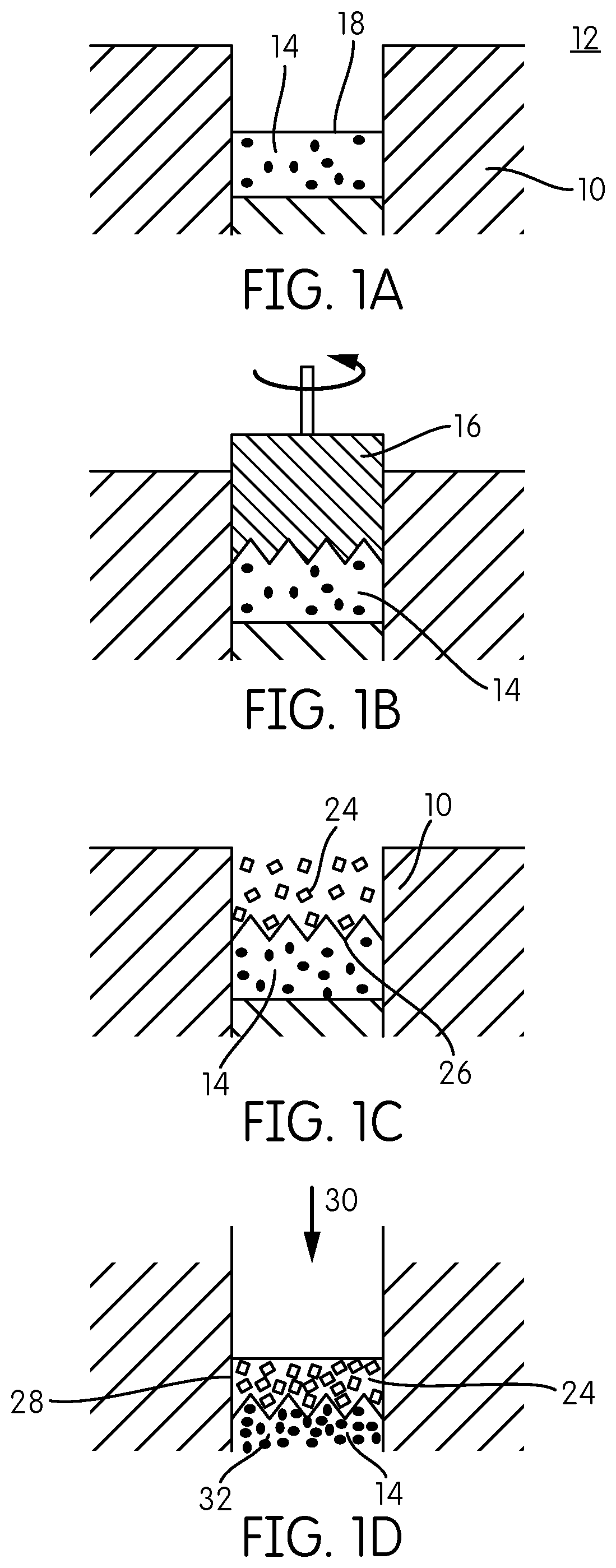

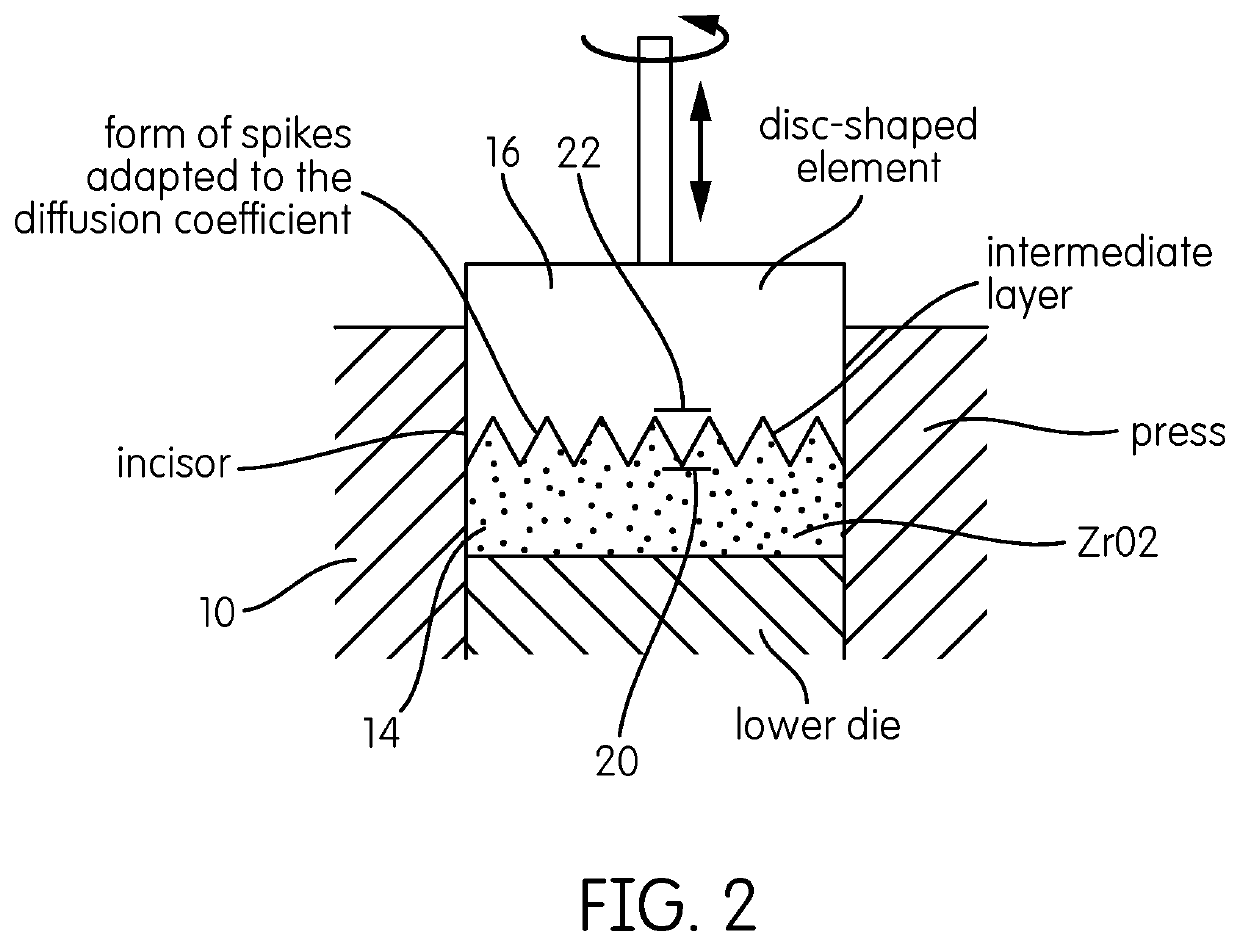

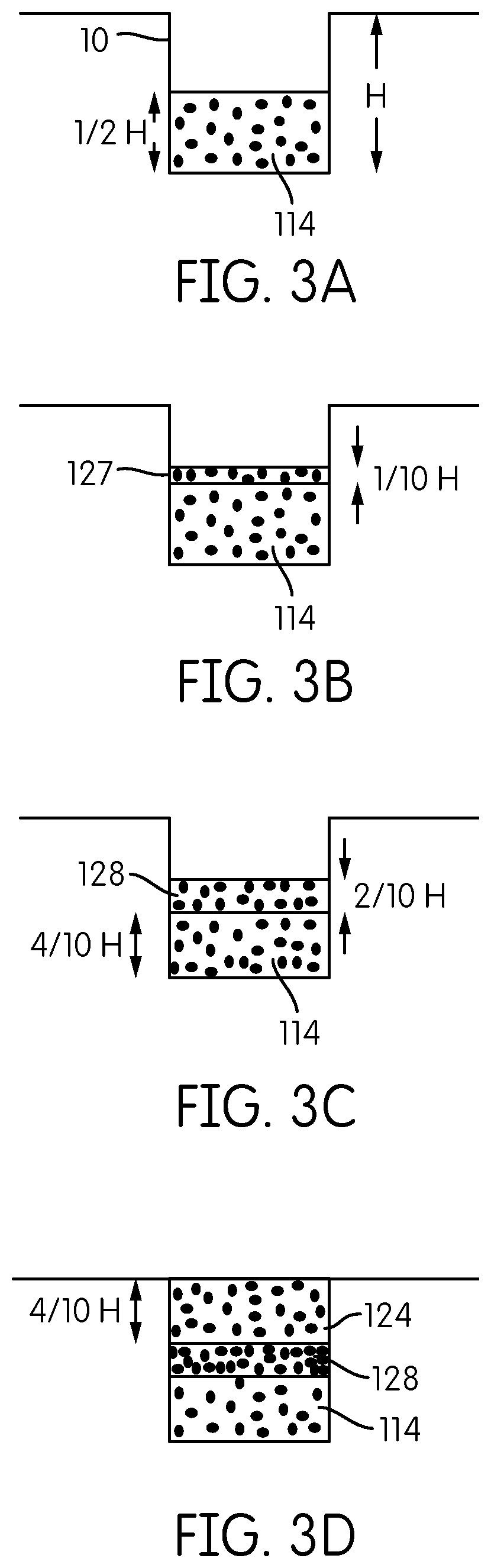

Method for producing a ceramic multilayer blank

The present invention is related to a method for producing a ceramic multilayer blank comprising at least a first layer of a first ceramic material and at least a second layer of a second ceramic material, wherein the first layer and the second layer are made of ceramic materials of different compositions, which are filled in pourable condition layer-by-layer into a mold and thereafter they are pressed and then sintered, wherein the first layer is a pink colored layer, wherein the first ceramic material comprises 2 to 25 wt % erbium oxide.

Owner:DENTSPLY SIRONA INC

Glass micro-beads for weather-resistant and wear-resistant reflective film and preparation method for glass micro-beads

The invention discloses glass micro-beads for a weather-resistant and wear-resistant reflective film and a preparation method for the glass micro-beads. The glass micro-beads are prepared from the following raw materials in parts by weight: 47 to 63 parts of quartz powder, 26 to 44 parts of apatite, 24 to 37 parts of gneiss, 18 to 34 parts of attapulgite, 12 to 26 parts of alunite, 8 to 14 parts of tungsten sulfide, 9 to 16 parts of titanium diboride, 5 to 10 parts of silicon nitride, 14 to 26 parts of light burning powder, 5 to 10 parts of erbium oxide, 5 to 10 parts of aluminum nitrate, 6 to 12 parts of sodium carbonate and 8 to 12 parts of an additive. According to the micro-beads, the advantages of the raw materials such as tungsten sulfide, titanium diboride and silicon nitride are combined, so that the comprehensive performance of conventional glass micro-beads is improved, and the glass micro-beads are endowed with high mechanical performance, weather and aging resistance, wear resistance and long service life, and can be applied to outdoor reflective films with higher requirements on weather resistance and wear resistance.

Owner:HEFEI DINGLIANG OPTICAL TECH

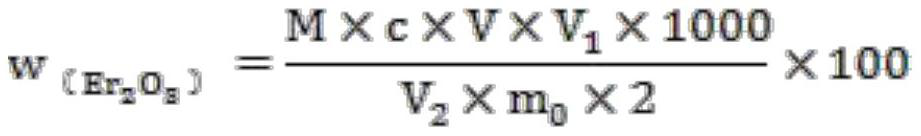

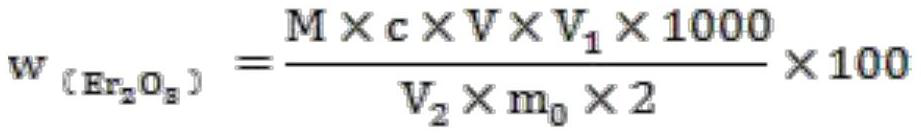

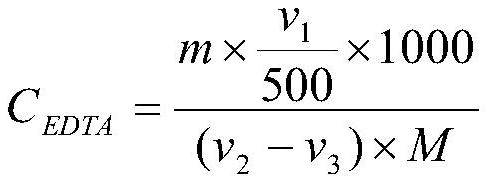

Erbium oxide purity detection method

InactiveCN112147271AImprove detection accuracyThe detection method is simpleChemical analysis using titrationMeth-Hexamethylenetetramine

The invention discloses an erbium oxide purity detection method. The erbium oxide purity detection method comprises the following steps of S1, taking erbium oxide to be detected, recording the mass ofthe erbium oxide to be detected as m0, adding a hydrochloric acid solution to the erbium oxide to be detected, heating to dissolve the erbium oxide to obtain a test solution, and recording the volumeof the test solution as V1; S2, taking a proper amount of the test solution to obtain a taken test solution, recording the volume of the taken test solution as V2, and adding ascorbic acid and a sulfosalicylic acid solution into the taken test solution; S3, taking methyl orange as an indicator, adjusting the solution to be yellow by using ammonia water and hydrochloric acid, and then adding a hexamethylenetetramine buffer solution; S4, taking xylenol orange as an indicator, taking an EDTA standard titration solution, recording the concentration of the EDTA standard titration solution as c, then carrying out complexometric titration until the solution turns yellow from red, and recording the volume of the consumed EDTA standard titration solution as V; and S5, calculating the mass percentage content of the erbium oxide. The method has the advantages that the detection accuracy of the high-purity (99.5% or above) erbium oxide is high, and the detection method is simple and convenient.

Owner:宜宾锂宝新材料有限公司

Preparation method for nano-silicon nitride ceramic material compounded by erbium oxide and praseodymium oxide

The invention relates to the technical field of ceramic material, in particular to a method for producing high-performance silicon nitride (Si3N4) ceramic via pressureless sintering by using erbium oxide and praseodymium oxide as additives. The silicon nitride ceramic comprises the following components in percentage by mass: 3-7% of erbium oxide, 5-8% of praseodymium oxide, and 85-92% of silicon nitride. The invention is aimed at overcoming the shortages in the prior art, and providing a method for producing high-performance silicon nitride ceramic via pressureless sintering by using erbium oxide and praseodymium oxide as additives, and the method can be widely used for preparing components and parts in the fields of chemical industry, machinery, metallurgy, aerospace, etc.

Owner:苏州中锆新材料科技有限公司

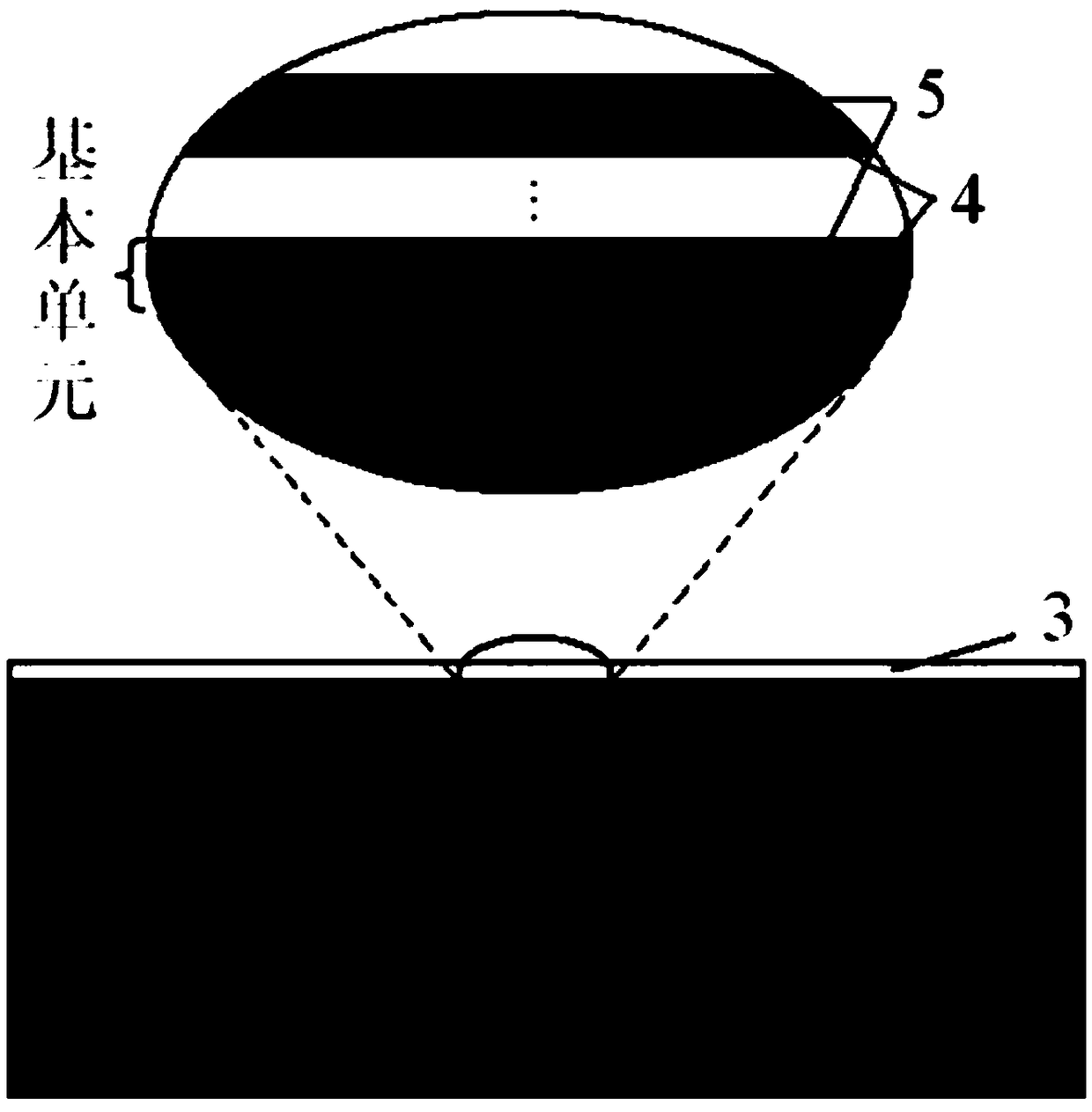

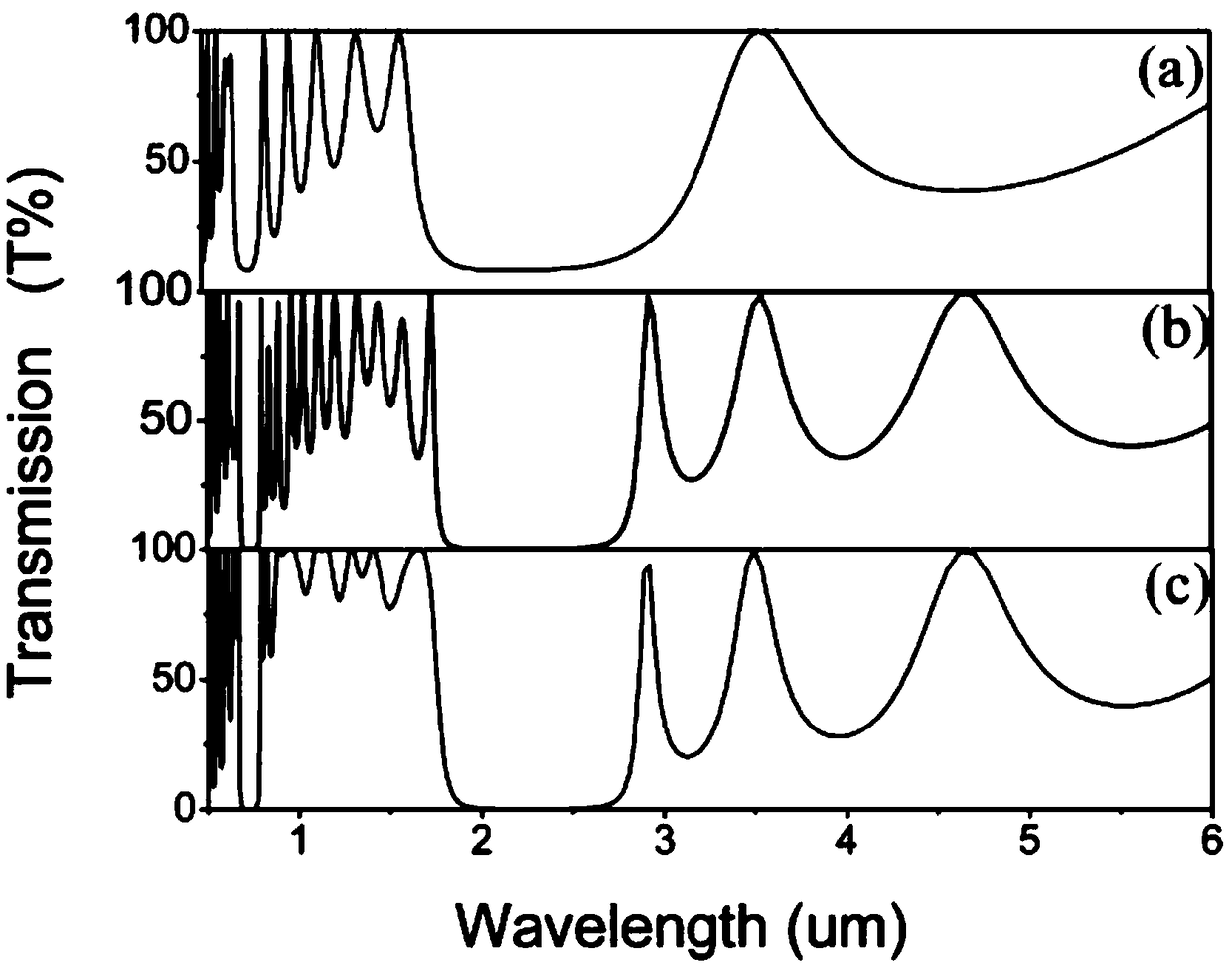

A selective infrared radiator

ActiveCN107104162BImprove photoelectric conversion efficiencyPhotovoltaic energy generationSemiconductor devicesPhotonic crystalThin membrane

Owner:SHAOXING UNIVERSITY

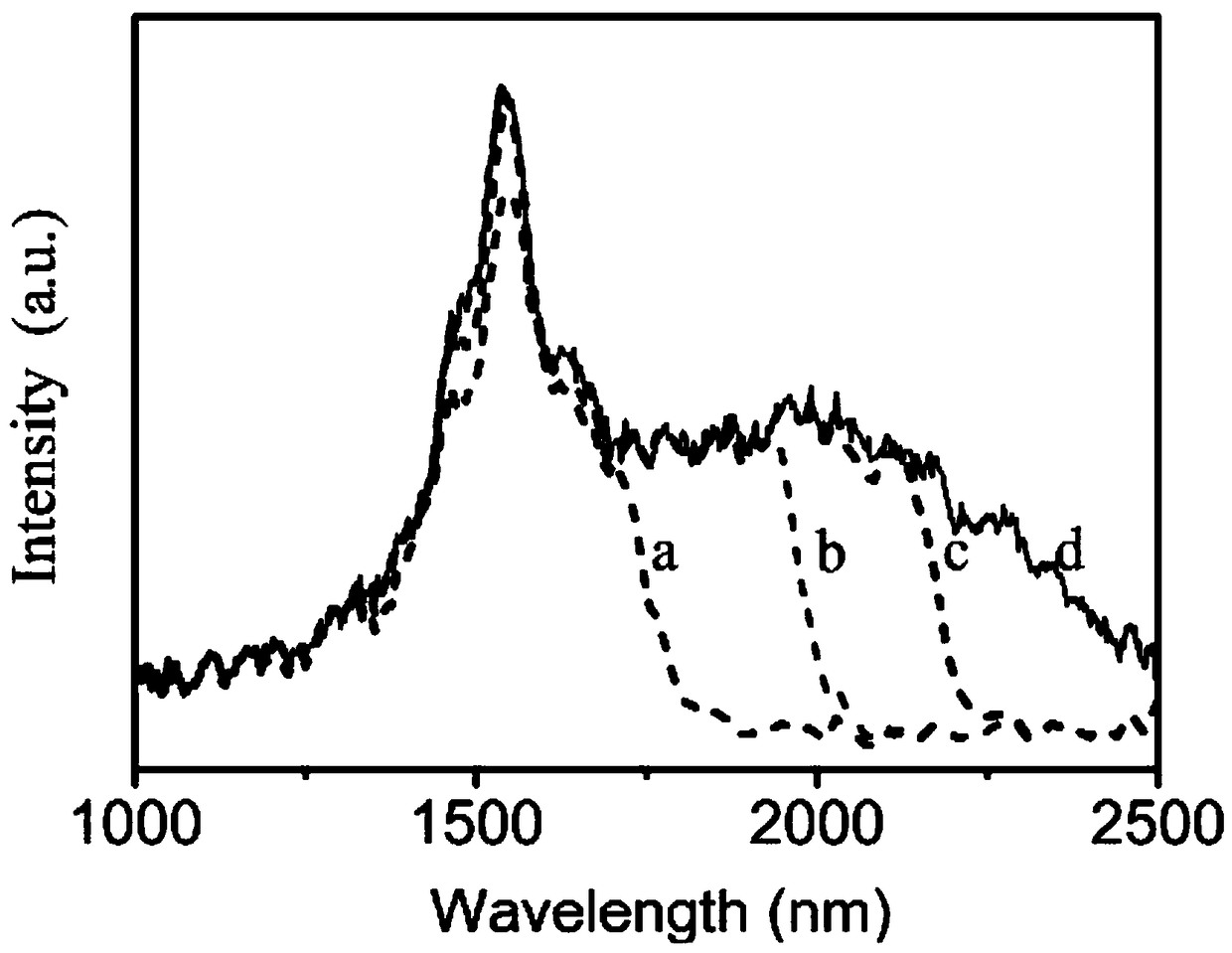

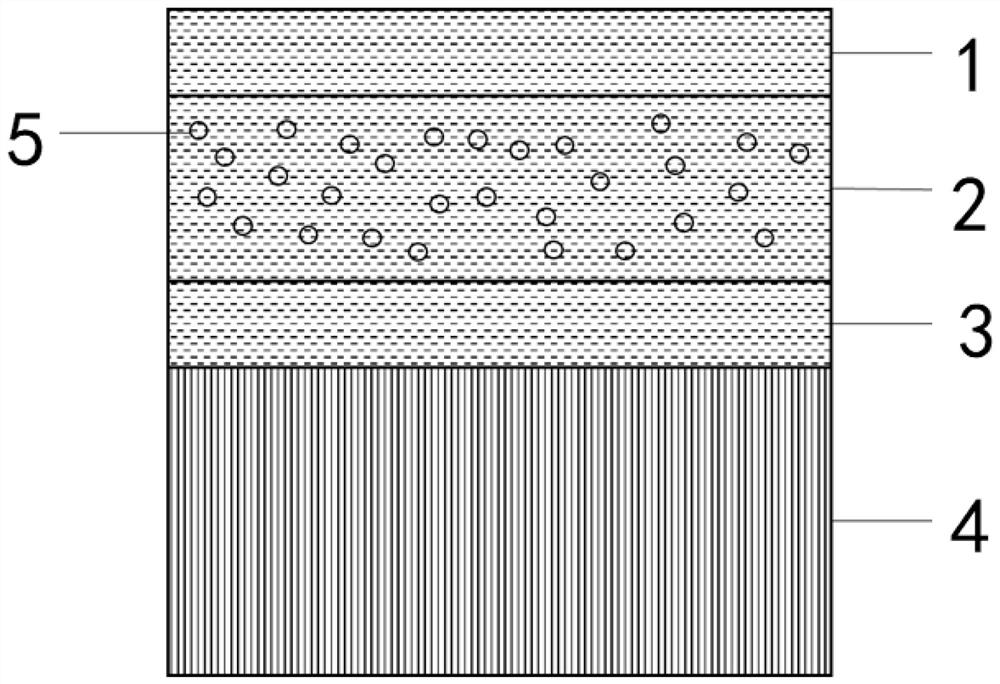

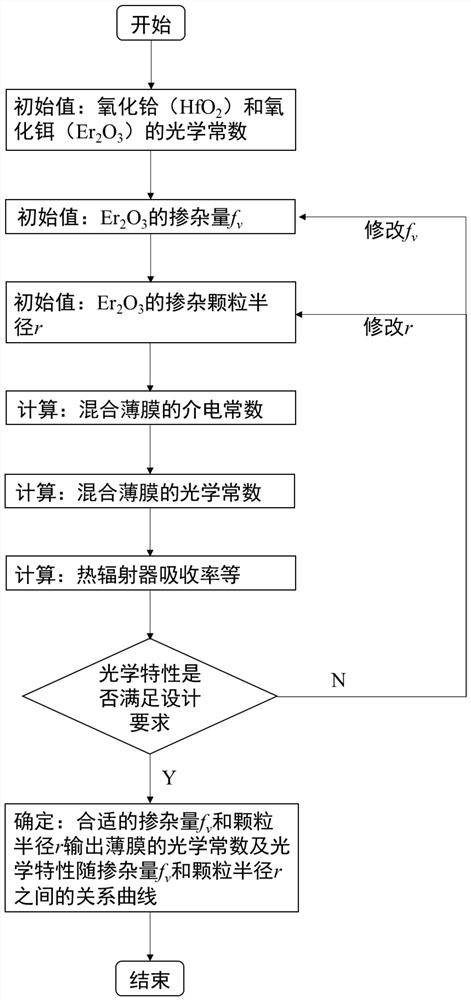

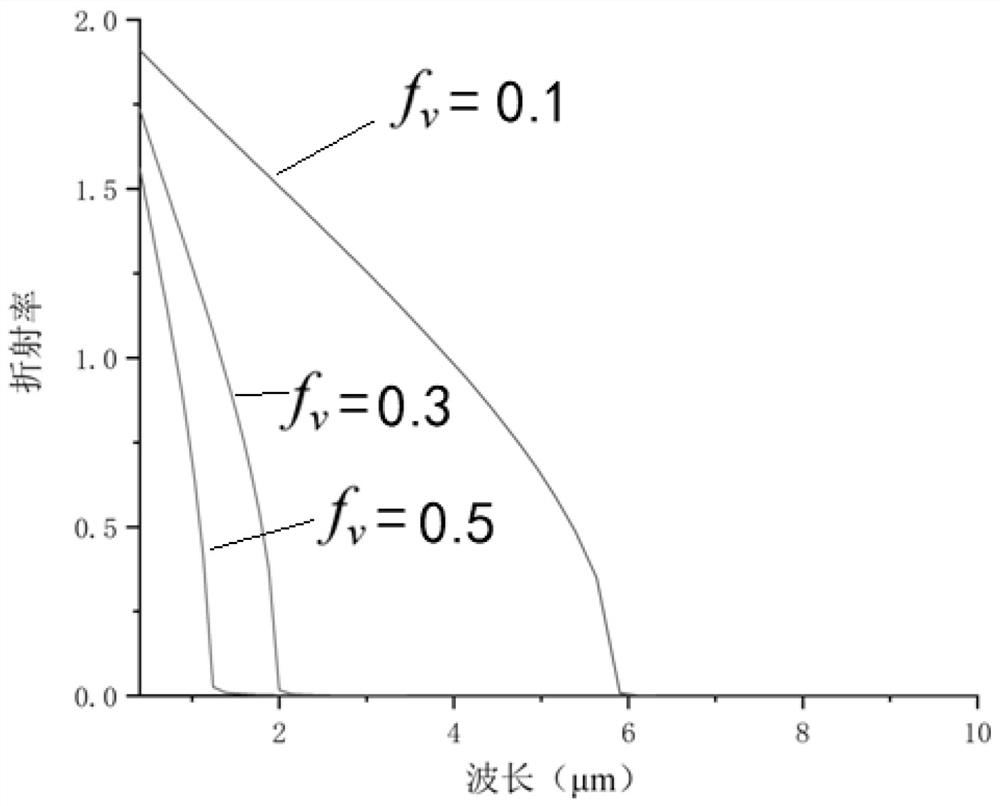

Spectrum Selective Thermal Radiator and Its Design Method

ActiveCN112687788BImprove thermal stabilityNot prone to chemical reaction changesDesign optimisation/simulationSpecial data processing applicationsSpectral emissionHeat stability

The invention relates to a spectrally selective thermal radiator and a design method thereof. The spectrally selective thermal radiator of the present invention is a one-dimensional layered structure, which includes a first layer, a second layer and a third layer arranged in sequence. The first layer and the third layer are hafnium oxide layers, and the second layer is a hafnium oxide layer distributed with a plurality of erbium oxide nanoparticles. The heat radiator designed in the present invention is a material-type spectrally selective heat radiator with selective emissivity. Compared with traditional structural heat radiators, material heat radiators have very high thermal stability and no oxidation, which can fundamentally eliminate the problem of high temperature decay in structural heat radiators. The invention has the characteristics of accuracy and high efficiency, and can comprehensively reveal the change law of the spectral emission characteristics of the material-type hafnium oxide-doped erbium oxide particle selective thermal radiator with the amount of erbium oxide doping and the size of the erbium oxide doping particles, and It lays the foundation for the practical application of high temperature selective radiators.

Owner:SUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com