Methane oxidative coupling catalyst, preparation method thereof and method for preparing C2 hydrocarbon by oxidative coupling of methane

An oxidative coupling and catalyst technology, applied in metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, physical/chemical process catalysts, etc., can solve the problem of insufficient catalytic activity and product selectivity, The preparation method is complex and other problems, to achieve high industrial application prospects, simple steps, and the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

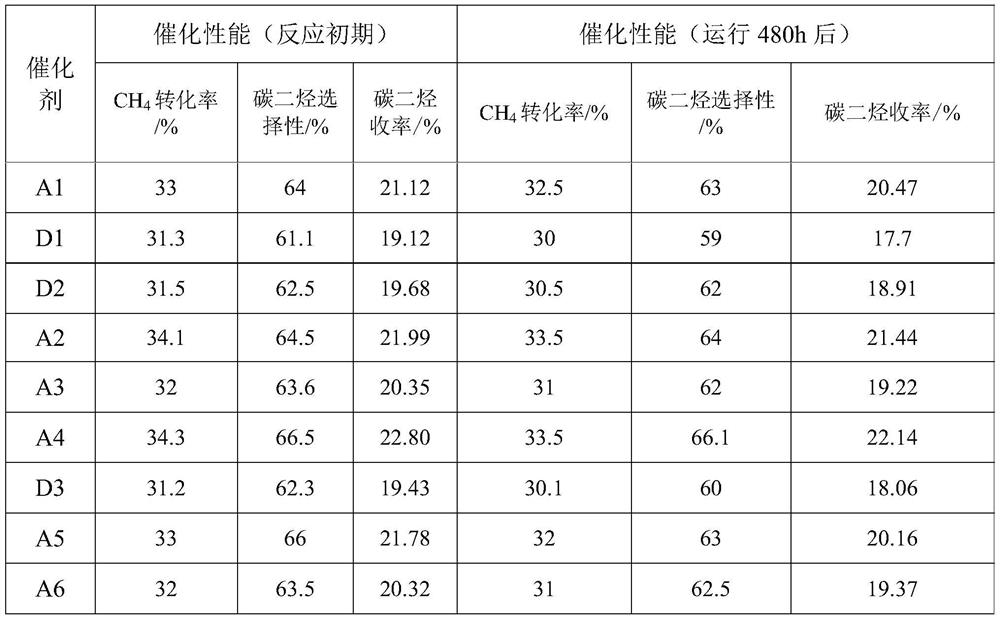

Examples

preparation example Construction

[0021] According to the second aspect of the present invention, the present invention provides a method for preparing a methane oxidative coupling catalyst, the preparation method comprising: in the presence of water, sodium tungstate, soluble salts of erbium, soluble salts of manganese and square The quartz is contacted, dried and calcined, so that the oxides of sodium tungstate, erbium oxide and manganese are supported on the cristobalite.

[0022] According to the preparation method of the present invention, the consumption of sodium tungstate, the soluble salt of erbium, the soluble salt of manganese and cristobalite make in the prepared catalyst, based on the weight of cristobalite, the content of sodium tungstate is 1-15% by weight, The content of erbium oxide is 0.01-10% by weight, and the content of manganese oxide is 0.1-6.5% by weight in terms of manganese.

[0023] According to the preparation method of the present invention, the consumption of sodium tungstate, the...

Embodiment approach

[0029] According to another specific embodiment, the preparation method of the catalyst comprises the following steps:

[0030] (1) In the presence of water, the aqueous solution of manganese-containing soluble salt and sodium tungstate is contacted with cristobalite, and then dried to obtain cristobalite impregnated with manganese and sodium tungstate;

[0031] (2) The cristobalite impregnated with manganese and sodium tungstate is brought into contact with the erbium soluble salt solution, followed by drying and firing.

[0032] In step (1), the cristobalite can be impregnated with an aqueous solution of a soluble salt of manganese and an aqueous solution of sodium tungstate, respectively, or can be impregnated with an aqueous solution of a soluble salt of manganese and sodium tungstate at the same time. The contacting is carried out under stirring, preferably at room temperature (20-45° C.) for 1-2 hours.

[0033] In step (2), the contacting is carried out under stirring, ...

Embodiment 1

[0050] (1) Preparation of aqueous solution for impregnation

[0051] 4.68 g of manganese nitrate solution was dissolved in 20 mL of water to obtain manganese nitrate aqueous solution. Dissolve 0.67 g of sodium tungstate dihydrate in 20 mL of water to obtain an aqueous solution of sodium tungstate. Dissolve 0.014 g of erbium nitrate pentahydrate in 20 mL of water to obtain an erbium nitrate solution.

[0052] (2) Preparation of catalyst

[0053] Add 12g of cristobalite carrier to manganese nitrate aqueous solution, stir at room temperature for 1h, and then dry at 120°C for 2h after rotary evaporation at 80°C for 3h to obtain manganese-impregnated carrier; then add sodium tungstate aqueous solution, stir at room temperature for 1h, After rotary evaporation for 2 hours, dry at 120°C for 2 hours to obtain a carrier impregnated with manganese and sodium tungstate; finally add erbium nitrate aqueous solution, stir at 50°C for 1 hour, rotate at 80°C for 3 hours, dry at 120°C for 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com