A kind of high temperature resistant and high entropy wave absorbing ceramic and its preparation method and application

A high-temperature, high-entropy technology, applied in chemical instruments and methods, boron/boride, inorganic chemistry, etc., can solve the problem of large adjustability of lattice accommodated metal atom size, low density and high temperature stability, and attenuation of wave absorption performance. and other problems, to achieve the effect of being suitable for large-scale production and application, good high temperature stability, and strong wave absorbing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The preparation method of high temperature resistant high entropy wave absorbing ceramics of the present invention comprises the following steps:

[0044] (1) mixing the raw material powder with absolute ethanol in a ball mill to obtain a well-mixed slurry;

[0045] (2) the obtained slurry is dried and sieved to obtain a mixed powder, and the powder is put into a high-temperature electric furnace for calcination to obtain a ceramic powder;

[0046] In step (2), the calcination temperature is 1900°C-2000°C, the calcination time is 1-2h, and the calcination vacuum degree is controlled to be 8-15Pa. The sintering temperature and time mainly affect the purity of the ceramic material. If the sintering temperature is too low and lower than the minimum value of the above range, the raw material powder cannot be fully reacted to obtain pure high-entropy hexaboron ceramics. The time is too short and shorter than the minimum value of the above range. When the sintering temperatu...

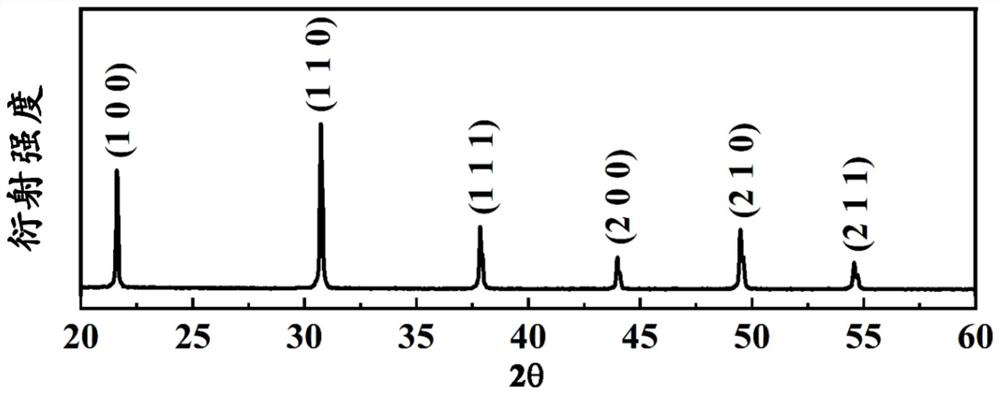

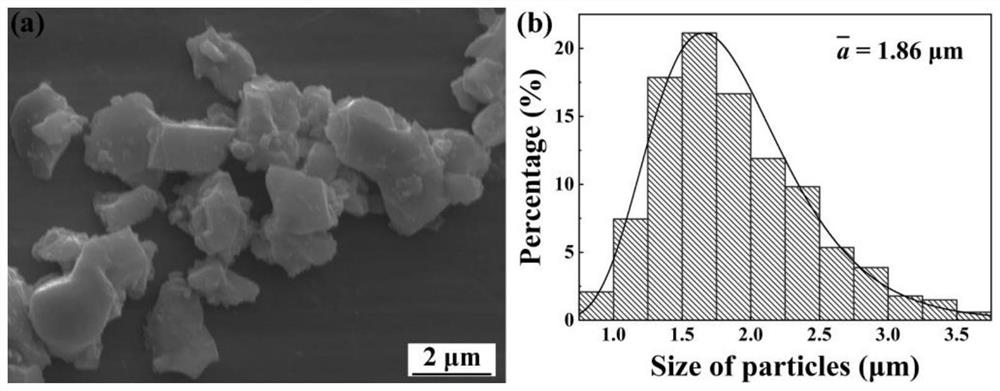

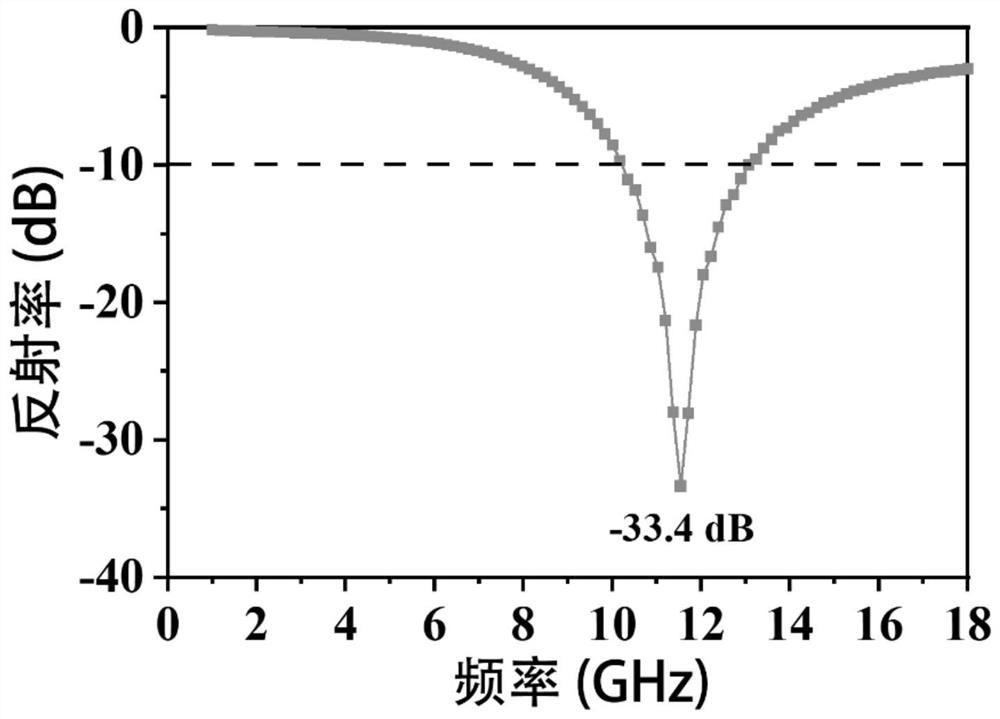

Embodiment 1

[0049] put Y 2 O 3 , Sm 2 O 3 , Eu 2 O3, Yb 2 O 3 , Er 2 O 3 and B 4 CPress Y 2 O 3 :Sm 2 O 3 :Eu 2 O 3 :Yb 2 O 3 :Er 2 O 3 :B 4The molar ratio of C=1:1:1:1:1:15 was weighed, mixed in a ball mill, the mixing time was 6 hours, the mixing medium was absolute ethanol, and a slurry was obtained; the obtained slurry was filtered and Carry out drying treatment and pass through a 120-mesh sieve to obtain the mixture powder, put the dried powder into a high-temperature furnace for calcination, the calcination temperature is 1900 ° C, the calcination time is 2 hours, and the vacuum degree is 8Pa, to obtain high-entropy hexaboride ceramics (Y 1 / 5 Sm 1 / 5 Eu 1 / 5 Yb 1 / 5 Er 1 / 5 )B 6 Powder, the ceramic purity is 100wt%, the average particle size is 1.86 microns, the maximum absorption loss at 2-18GHz frequency measured by Agilent N5244A vector network analyzer is 33.4dB, and the maximum absorption frequency bandwidth when the reflectivity is below -10dB 3.9GHz. Th...

Embodiment 2

[0051] put Y 2 O 3 , Sm 2 O 3 , Eu 2 O3, Yb 2 O 3 , Er 2 O 3 and B 4 CPress Y 2 O 3 :Sm 2 O 3 :Eu 2 O 3 :Yb 2 O 3 :Er 2 O 3 :B 4 The molar ratio of C=1:1:1:1:1:15 was weighed, mixed in a ball mill, the mixing time was 6 hours, and the mixing medium was anhydrous ethyl alcohol to obtain a slurry; the obtained slurry was Filter and dry and pass through a 120-mesh sieve to obtain the mixture powder, put the dried powder into a high-temperature furnace for calcination, the calcination temperature is 2000 ° C, the calcination time is 1 hour, and the vacuum degree is 15 Pa, to obtain high-entropy hexaboron chemical ceramics (Y 1 / 5 Sm 1 / 5 Eu 1 / 5 Yb 1 / 5 Er 1 / 5 )B 6 Powder, the ceramic purity is 100wt%, the average particle size is 2.1 microns, the maximum absorption loss at 2-18GHz frequency measured by Agilent N5244A vector network analyzer is 30dB, and the maximum absorption frequency bandwidth when the reflectivity is below -10dB is 3.6GHz.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com