EITZO target material and preparation method thereof

A target and metal oxide technology, applied in the target field, can solve the problems of low mobility and high cost, and achieve the effects of improving mobility, reducing grain size, and improving resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

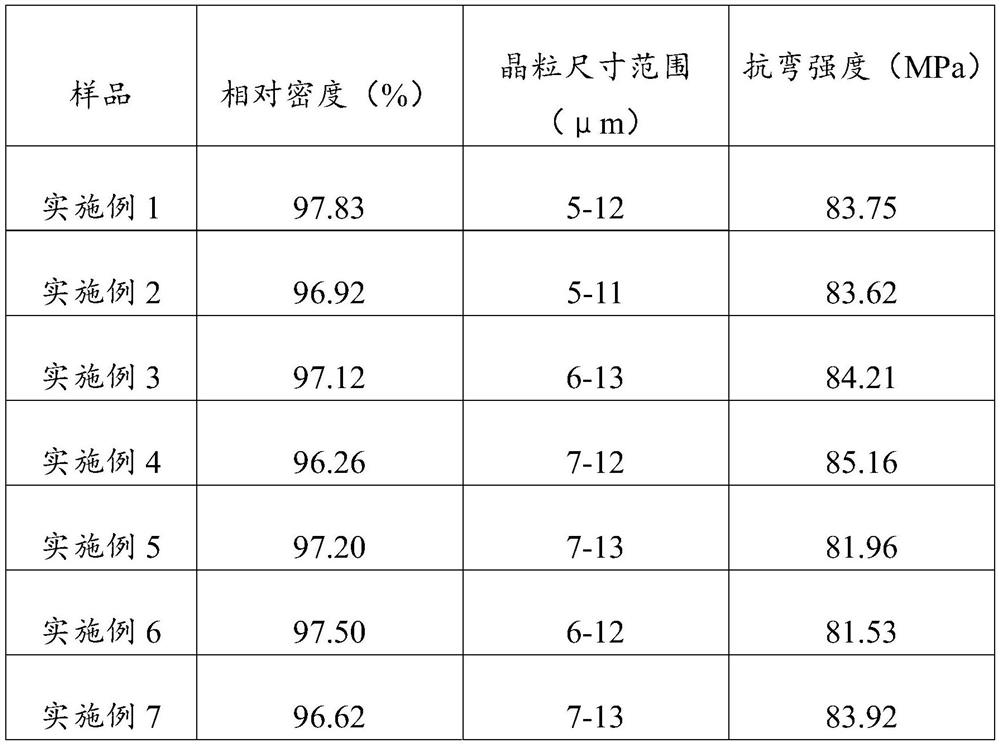

Examples

Embodiment 1

[0030] As an EITZO target in this embodiment, the EITZO target includes a metal oxide composition, and the metal oxide composition includes the following components by weight: 52% indium oxide, 26% tin oxide, 6% erbium oxide and 16% zinc oxide;

[0031] The preparation process of the EITZO target includes: pressing the metal oxide composition into a billet and then sintering.

[0032] The preparation method of the EITZO target material of the present embodiment comprises the following steps:

[0033] (1) Indium oxide, tin oxide, erbium oxide, zinc oxide are used according to the weight ratio, and ammonium polyacrylate is used as a dispersant, and pure water is ball milled for 4 hours to obtain a mixed powder. The D50 of the mixed powder is less than 0.5 μm. The half peak width of the powder is less than 0.5;

[0034] (2) mixing, stirring and dispersing the mixed powder, binder and deionized water for 2 hours to obtain a mixed slurry, the solid content (weight) of the mixed s...

Embodiment 2

[0039] As an EITZO target in the embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the metal oxide composition includes the following components by weight: 50% indium oxide, 25% tin oxide, 8% Erbium oxide and 17% zinc oxide.

Embodiment 3

[0041] As an EITZO target in the embodiment of the present invention, the only difference between this embodiment and Embodiment 1 is that the metal oxide composition includes the following components by weight: 50% indium oxide, 26% tin oxide, 7% Erbium oxide and 17% zinc oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com