High-strength high-modulus fluororubber composition as well as preparation method and application thereof

A technology of fluororubber and high modulus, which is applied in the field of high-strength and high-modulus fluororubber composition and its preparation, and can solve problems such as poor sealing and pressure bearing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

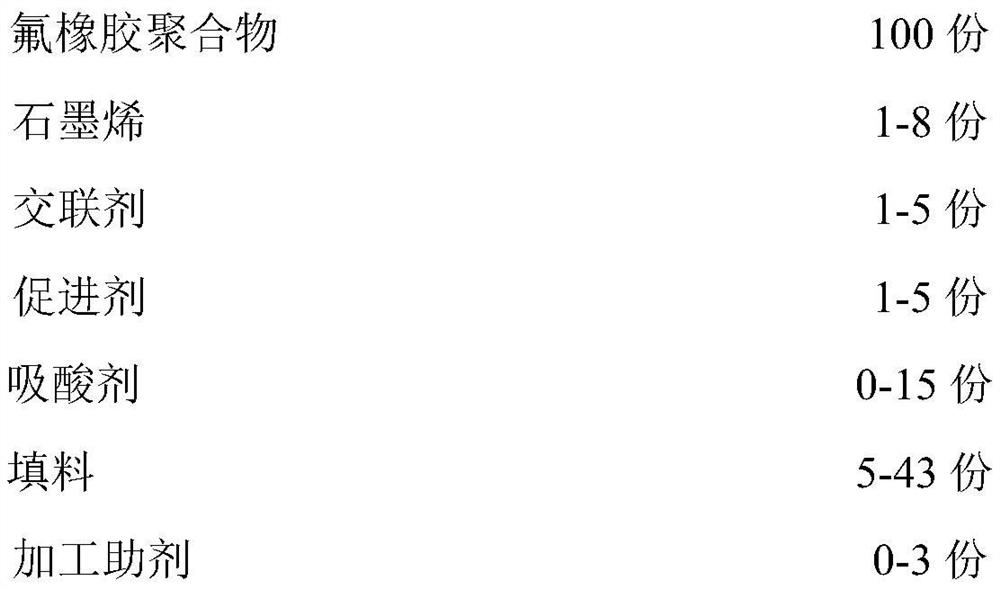

[0026] Embodiment 1, the formula of fluororubber composition

[0027] Table 1 shows the formulations of No. 1-8 fluororubber compositions. For detailed proportions, please refer to the weight ratio of each component in Table 1.

[0028] Table 1, the formula of No. 1-8 fluororubber composition

[0029] number 1 number 2 number 3 No 4 Number 5 number 6 Number 7 number 8 Fluorine rubber Viton AHV 100.00 100.00 100.00 100.00 100.00 100.00 100.00 100.00 Calcium Hydroxide NICC5000 6.00 6.00 6.00 6.00 6.00 6.00 6.00 6.00 Magnesium Oxide MA150 3.00 3.00 3.00 3.00 3.00 3.00 3.00 3.00 Crosslinking agent bisphenol AF50 3.20 3.20 3.20 3.20 3.20 3.20 3.20 3.20 Accelerator BP33 1.20 1.20 1.20 1.20 1.20 1.20 1.20 1.20 Graphene SE-A 2.00 5.00 10.00 Graphene SE-B 2.00 5.00 Graphene SE-C 2.00 5.00 Carbon black N990 20.00 20.00 20.00 20.00 20....

Embodiment 2

[0034] Embodiment 2, performance test of fluororubber composition

[0035] Weigh each component according to the weight and number ratio of each component of the No. 1-8 fluororubber composition formula in Table 1, wrap the fluororubber on a double-roll mill, and wrap graphene, crosslinking agent, accelerator Auxiliary materials such as agent, acid absorbing agent, carbon black and processing aids are added to the open mill and mixed with fluororubber, and the left and right sides of the rubber mixture are cut 5-10 times each, and the roller distance of the open mill is adjusted to the minimum. Or make a triangular bag 10 times, the whole mixing time is controlled between 15-20 minutes, and the roller temperature is lower than 80°C, and the mixture is uniformly mixed and the sheet is produced to obtain a fluorine rubber compound. The mixed rubber was molded and vulcanized into a standard rubber test piece at a temperature of 180°C for 10 minutes under the condition of one-stag...

Embodiment 3

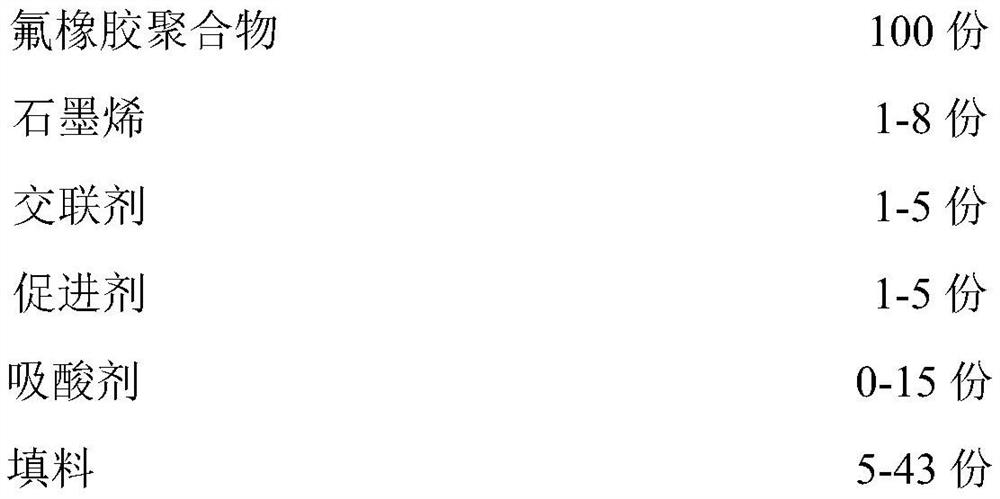

[0051] Embodiment 3, the prescription of fluororubber composition

[0052] Table 3 shows the formulations of No. 9 to No. 17 fluororubber compositions. For detailed proportions, refer to the weight ratio of each component in Table 3.

[0053] Formulation of No. 9-17 fluororubber composition of table 3.

[0054] Among them, in Table 3,

[0055] Graphene XF-A is graphene prepared by physical method-liquid phase exfoliation, black powder, thickness 1-5nm, sheet diameter 1-6um, carbon content > 99%, electrical conductivity 550-1100S / cm, bulk density 0.04 -0.07g / cm 3 , tap density 0.06-0.10g / cm 3 ;

[0056] Graphene SE-A, graphene SE-B are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com