Material surface modification method, modified material and application thereof, and medical product

A surface modification and product technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, bone/connective tissue cells, etc., can solve the problems of long time, inability to simultaneously regulate physical and chemical properties, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

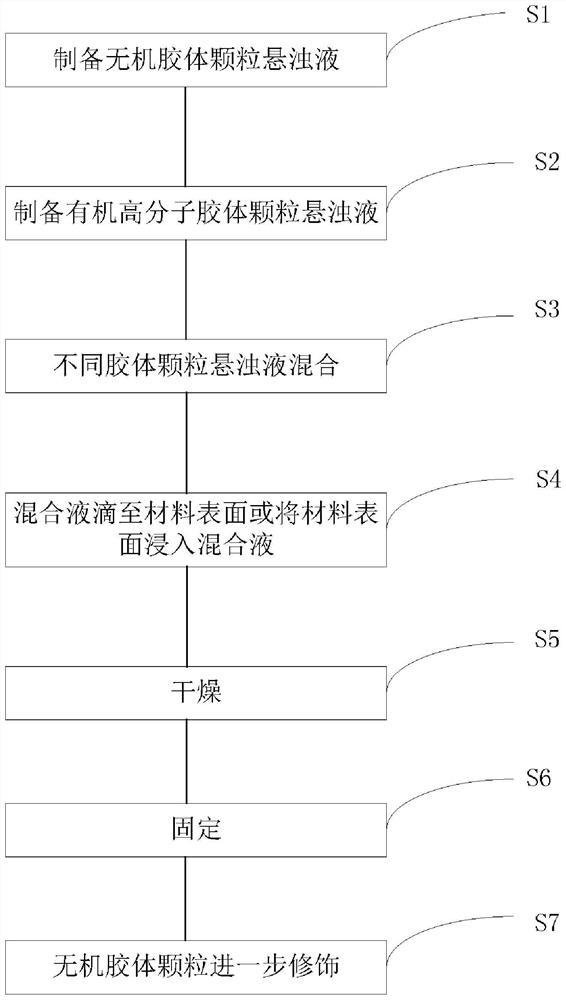

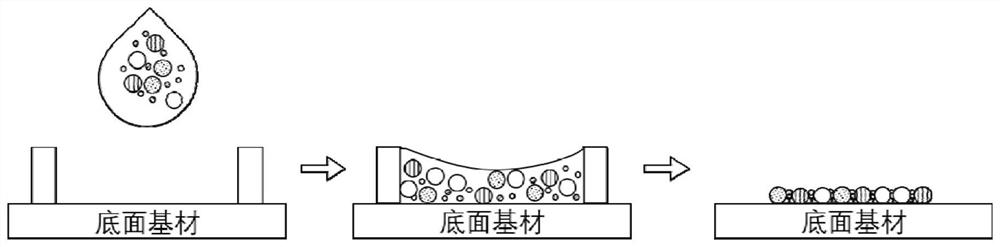

Method used

Image

Examples

Embodiment approach

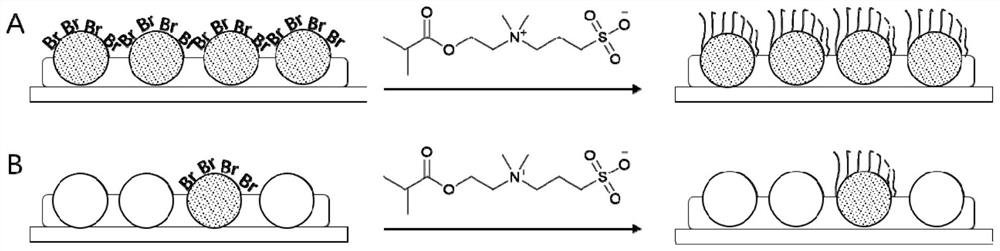

[0072] For example, in one embodiment, the inorganic colloidal particles are one kind (such as SiO 2 microspheres), then SiO 2 The same type of chemically modified SiO can be included in the microspheres 2 Microspheres (such as SiO 2 -X), can also contain many different kinds of chemically modified SiO 2 Microspheres (such as SiO 2 -X, SiO 2 -Y, SiO 2 Any combination of two or more of -Z, etc.), wherein X, Y, and Z represent different modifying groups.

[0073] For example, in another embodiment, the inorganic colloidal particles are several types (such as SiO 2 Microspheres and TiO 2 combination of microspheres), then SiO 2 Microspheres and TiO 2 Microspheres can contain the same type of chemically modified SiO 2 Microspheres (such as SiO 2 -X) and / or TiO 2 Microspheres (such as TiO 2 -X), can also contain many different kinds of chemically modified SiO 2 Microspheres and / or TiO 2 Microspheres (such as SiO 2 -X, SiO 2 -Y, SiO 2 -Z, TiO 2 -X 1 、TiO 2 -Y 2...

Embodiment 1

[0117] Example 1 Preparation of SiO with a particle size of 5 μm 2 -NH 2 , SiO 2 -Epoxy (silica microspheres with glycidyl groups on the surface), SiO 2 -RGD, SiO 2 -Br and SiO with a particle size of 5 μm 2 -SBMA

[0118] (1) 50 mg of SiO with a particle size of 5 μm 2Add spheres and 5mL anhydrous tetrahydrofuran (THF) into a round-bottomed flask, and disperse the microsphere particles to form a uniform suspension by repeated ultrasonication and vibration; add 200μL 3-aminopropyltrimethoxysilane under stable stirring of the suspension , and kept stirring for 24 hours; after the reaction, the mixture was transferred to a centrifuge tube to collect the microspheres by centrifugation, the microspheres were washed three times with THF and alcohol respectively, and then heated to 100 ° C for 3 hours to obtain SiO 2 -NH 2 ;

[0119] (2) 50 mg of SiO with a particle size of 5 μm 2 Add the balls and 5 mL of anhydrous THF into a round bottom flask, and disperse the microspher...

Embodiment 2

[0123] Example 2 Preparation of SiO with a particle size of 2 μm 2 -Br and SiO with a particle size of 2 μm 2 -SBMA

[0124] Step (1) uses SiO with a particle size of 2 μm 2 Ball, all the other steps are identical with embodiment 1.

[0125] The colloidal particles SiO synthesized by embodiment 1 and embodiment 2 2 -NH 2 , SiO 2 -Br and SiO 2 -SBMA were verified by XPS scanning, and the results are shown in Table 1.

[0126] Table 1 XPS element scanning results (atom%)

[0127]

[0128] The results in Table 1 show that, compared to SiO 2 , SiO 2 -NH 2 The appearance of nitrogen in the sample can prove the successful grafting of amino groups; SiO 2 -Epoxy samples compared to SiO 2 The increase in the ratio of sample carbon to oxygen proves the access of a small amount of epoxy groups (tested SiO 2 The ratio of carbon to oxygen is 0.16, SiO 2 -Epoxy is 0.47, and the ratio of the two elements in the epoxy monomer is 2.4, which proves that a small amount of epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com