Self-dispersion water-based electric heating slurry and preparation method thereof

A self-dispersing, water-based technology, applied in the direction of electric heating devices, conductive coatings, heating element materials, etc., can solve problems such as difficult to disperse, difficult to obtain high volume filling rate, and easy agglomeration of carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

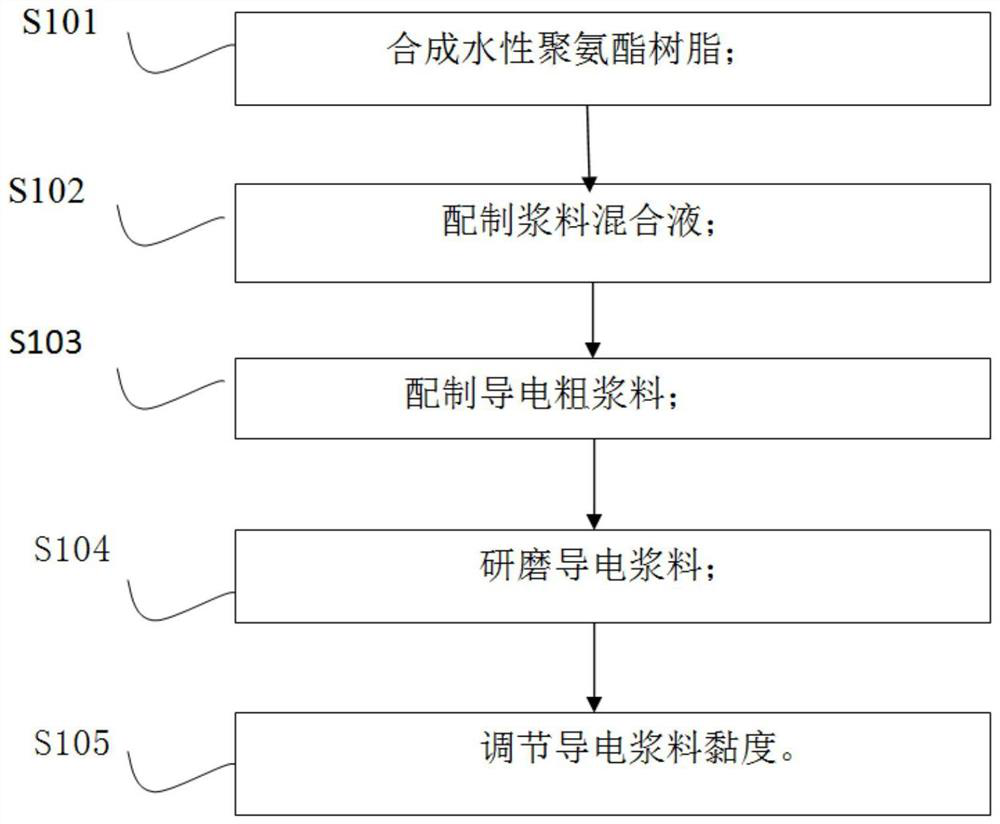

Method used

Image

Examples

Embodiment 1

[0039] This embodiment provides a self-dispersing water-based electric heating slurry, which includes the following components by weight: 35% water-based auxiliary dispersion resin, 5% conductive nano-carbon black, 20% conductive graphite, 6% graphene, 10% film-forming agent , 0.1% defoamer, 0.1% leveling agent, 23.8% deionized water.

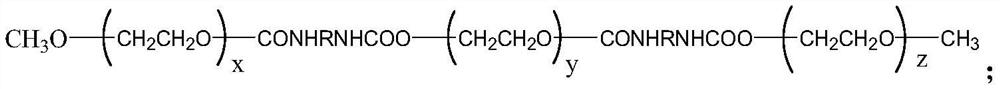

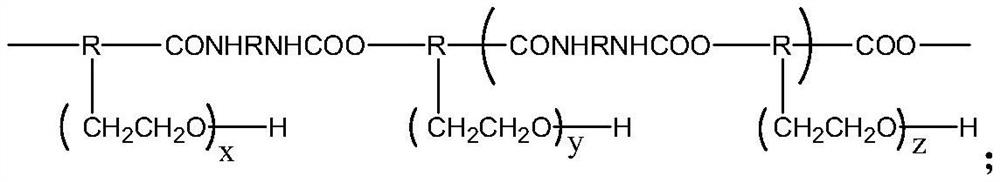

[0040] In a preferred embodiment, the water-based dispersing aid resin is one or more of non-ionic polyether-polyurethane resin, methacrylic-terminated polyether-polyurethane comb polymer, and polyether-polyurethane-terminated polymer The purpose is to introduce anchor groups and hydrophilic groups in the molecular chain, where the anchor groups are mainly hydrocarbon chains and aryl groups, and the hydrophilic groups are mainly hydroxyl groups and ether chains. In addition, in the present embodiment, It can effectively introduce hydroxyl groups and ether chains into the system. The introduction of hydroxyl groups enables resin molecules to for...

Embodiment 2

[0060] A self-dispersing water-based electric heating slurry, which includes the following components by weight percentage: 20% water-based auxiliary dispersion resin, 25% conductive nano-carbon black, 10% conductive graphite, 2% graphene, 5% film-forming agent, 0.2% disinfectant Foaming agent, 0.8% leveling agent, 47% deionized water.

[0061] In a preferred embodiment, the water-based dispersing aid resin is one or more of non-ionic polyether-polyurethane resin, methacrylic-terminated polyether-polyurethane comb polymer, and polyether-polyurethane-terminated polymer The purpose is to introduce anchor groups and hydrophilic groups in the molecular chain, where the anchor groups are mainly hydrocarbon chains and aryl groups, and the hydrophilic groups are mainly hydroxyl groups and ether chains. In addition, in the present embodiment, It can effectively introduce hydroxyl groups and ether chains into the system. The introduction of hydroxyl groups enables resin molecules to fo...

Embodiment 3

[0081] A self-dispersing water-based electric heating slurry, which includes the following components in weight percentage: 30% water-based auxiliary dispersion resin, 10% conductive nano-carbon black, 12% conductive graphite, 3% graphene, 5% film-forming agent, 1% disinfectant Foaming agent, 0.7% leveling agent, 38.3% deionized water.

[0082] In a preferred embodiment, the water-based dispersing aid resin is one or more of non-ionic polyether-polyurethane resin, methacrylic-terminated polyether-polyurethane comb polymer, and polyether-polyurethane-terminated polymer The purpose is to introduce anchor groups and hydrophilic groups in the molecular chain, where the anchor groups are mainly hydrocarbon chains and aryl groups, and the hydrophilic groups are mainly hydroxyl groups and ether chains. In addition, in the present embodiment, It can effectively introduce hydroxyl groups and ether chains into the system. The introduction of hydroxyl groups enables resin molecules to fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com