Zein-based uniaxial electrostatic spinning oriented fiber membrane and preparation method thereof

A zein, electrospinning technology, applied in cellulose/protein conjugated rayon, fiber processing, filament/thread forming, etc., can solve problems such as poor mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A method for preparing a zein-based uniaxial electrospinning oriented fiber film, comprising the following steps:

[0036] step 1:

[0037] Configuration volume concentration is 80% ethanol aqueous solution;

[0038] Dissolve polyethylene oxide and zein powder in ethanol aqueous solution, keep stirring at room temperature until the solution is fully mixed to obtain a mixed spinning solution; wherein, according to the mass ratio, polyethylene oxide:zein=1 : 10, the mass percentage concentration of polyethylene oxide and zein sum is 19%;

[0039] Step 2:

[0040] Put the mixed spinning solution in the electrospinning syringe, set the inner diameter of the needle of the syringe to 0.51mm, set the feed rate of the speed-controllable propeller to 2mL / h, connect the needle to the positive pole of the high DC power supply, and adjust the voltage to 15kV, the distance between the tip of the needle of the syringe and the surface of the grounded collector is 15cm, the controll...

Embodiment 2

[0042] With embodiment 1, difference is:

[0043] In this example, the addition amount of zein is 3:10.

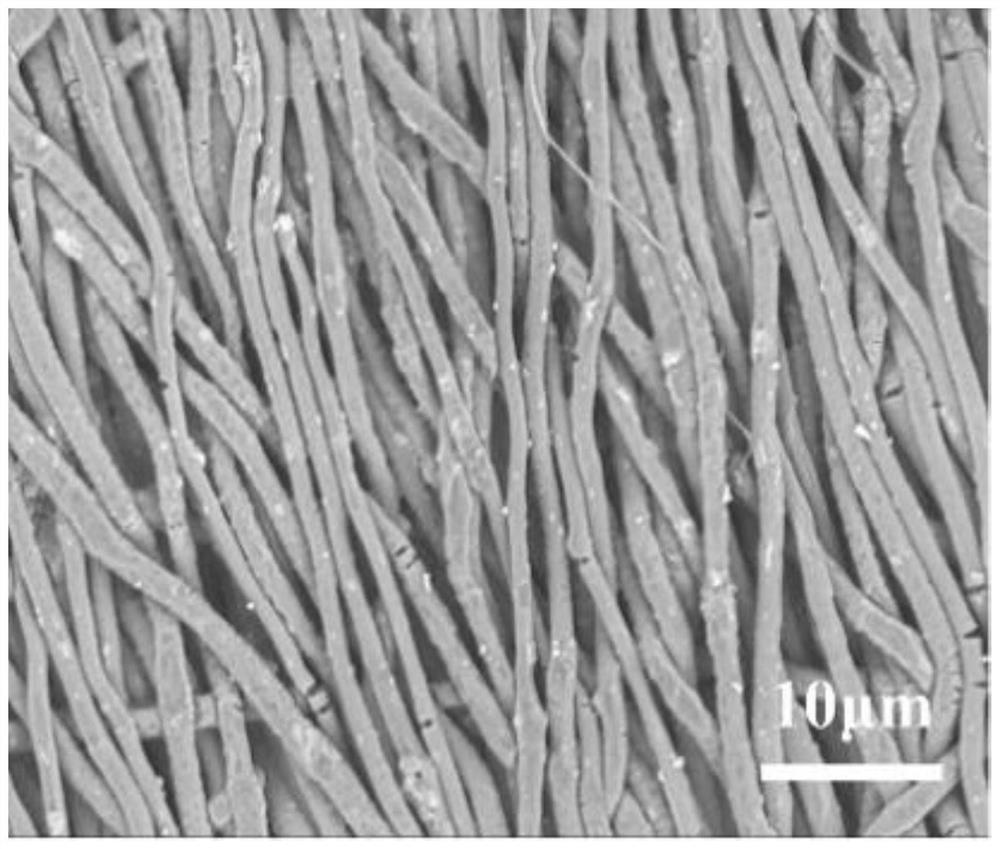

[0044] The SEM morphology of the fiber membrane prepared by electrospinning the prepared polyethylene oxide and zein mixture solution is shown in figure 2 ,From figure 2 It can be seen that the prepared fiber membranes have consistent orientation.

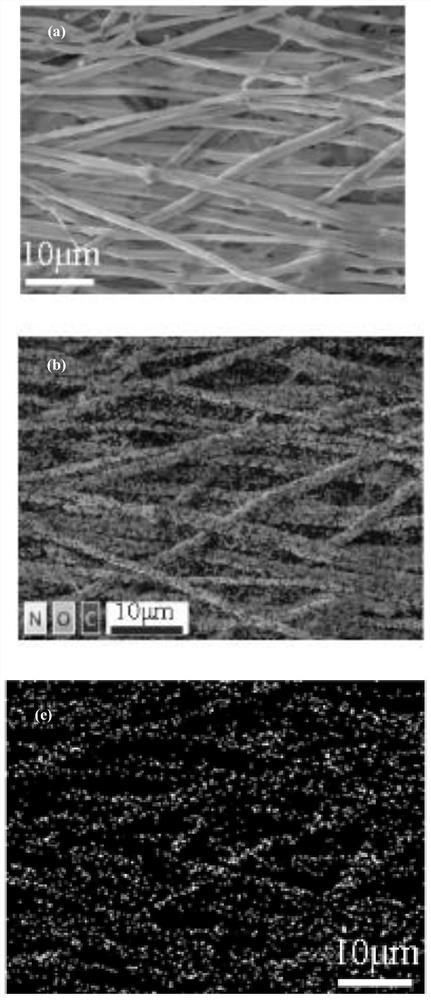

[0045] The elemental distribution diagram of the fiber membrane prepared by electrospinning the prepared polyethylene oxide and zein mixture solution is shown in image 3 , which is measured by ESD, there is no obvious difference in the smooth fiber surface, and there is no phase separation between zein and polyethylene oxide during the electrospinning process and there is good biocompatibility.

[0046] Orientation analysis diagram of the fiber membrane prepared by electrospinning the mixed solution of polyethylene oxide and zein is shown in Figure 4 , from the digitized fibrous microstructure, structural features with ...

Embodiment 3

[0054] With embodiment 1, difference is:

[0055] In this example, the addition amount of zein is 5:10.

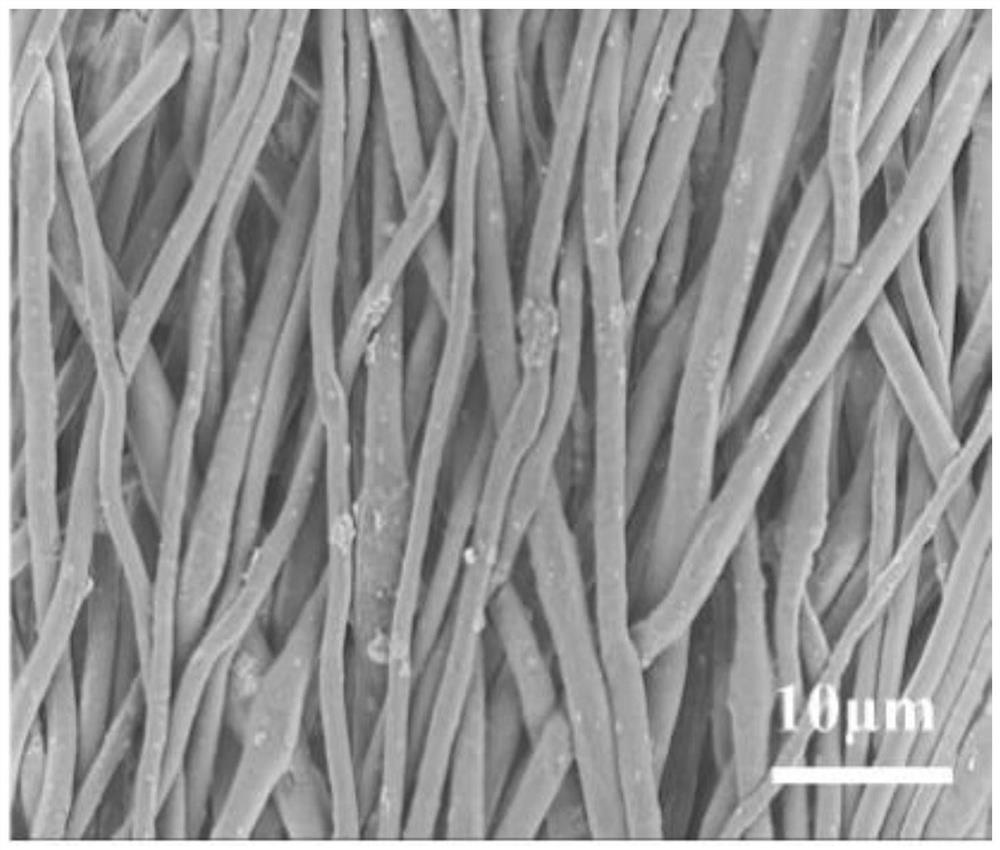

[0056] The SEM morphology of the fiber membrane prepared by electrospinning the prepared polyethylene oxide and zein mixture solution is shown in Figure 6 , and its degree of orientation is 0.87.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

| Tensile stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com