Glutamate oxidase biosensor and its preparation method and application

A glutamate oxidase and biosensor technology, which is applied in the field of electrochemical biosensors, can solve the problem that sodium glutamate detection has not been reported in literature, achieve good selectivity and stability, improve detection performance, and has wide application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

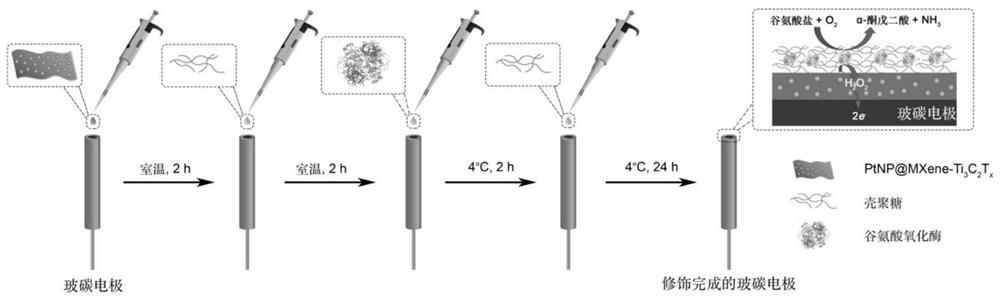

[0048] Prepare a glutamate oxidase biosensor, the specific steps are as follows:

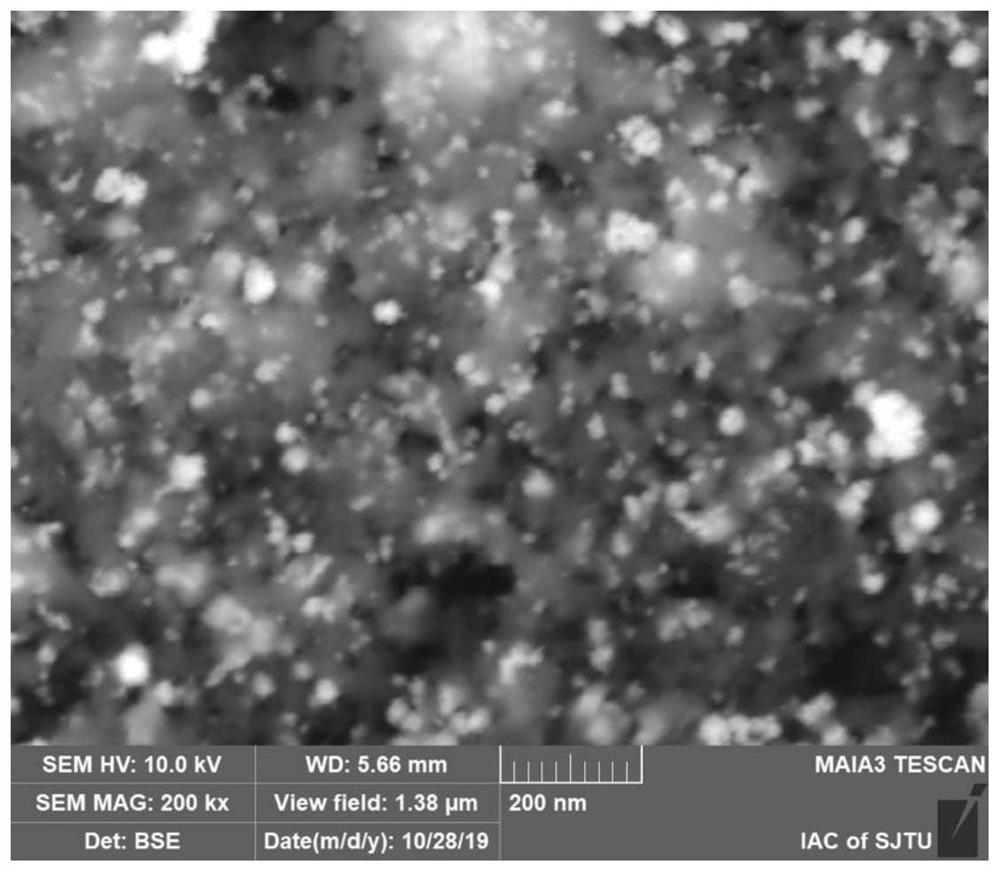

[0049] (1) First prepare PtNP@MXene-Ti 3 C 2 T x composite nanomaterials. Prepare 10mL of 1mg / mL MXene-Ti 3 C 2 T x The solution was sonicated for 10 minutes, 2.5 mL of 10 mg / mL chloroplatinic acid was added, and after 10 minutes of sonication, it was continuously reduced for 24 hours under the protection of nitrogen. The product was centrifuged at 9500 rpm for 10 min, washed with ethanol and lyophilized. The lyophilized product was formulated into a 0.5 mg / mL solution to obtain PtNP@MXene-Ti 3 C 2 T x nanocomposites. The scanning electron microscope image of the material is as figure 1 As shown, it can be clearly observed that the nano-platinum particles are attached to the sheet-like MXene-Ti 3 C 2 T x surface, indicating that PtNP@MXene-Ti 3 C 2 T x successful synthesis.

[0050] (2) Surface pretreatment of the working electrode. The glassy carbon electrode was polished to...

Embodiment 2

[0058] Prepare a glutamate oxidase biosensor, the specific steps are as follows:

[0059] (1) First prepare PtNP@MXene-Ti 3 C 2 T x composite nanomaterials. Prepare 10mL of 1mg / mL MXene-Ti 3 C 2 T x The solution was sonicated for 10 minutes, 2.5 mL of 10 mg / mL chloroplatinic acid was added, and after 10 minutes of sonication, it was continuously reduced for 24 hours under the protection of nitrogen. The product was centrifuged at 9500 rpm for 10 min, washed with ethanol and lyophilized. The lyophilized product was formulated into a 0.5 mg / mL solution to obtain PtNP@MXene-Ti 3 C 2 T x nanocomposites.

[0060] (2) Surface pretreatment of the working electrode. The glassy carbon electrode was polished to a mirror surface on a polishing cloth with 0.3 μm and 0.05 μm alumina powder in turn, rinsed with ultrapure water, and dried with nitrogen to obtain a pretreated glassy carbon electrode.

[0061] (3) The modification process of the working electrode is as follows: f...

Embodiment 3

[0069]Prepare a glutamate oxidase biosensor, the specific steps are as follows:

[0070] (1) First prepare PtNP@MXene-Ti 3 C 2 T x composite nanomaterials. Prepare 10mL of 1mg / mL MXene-Ti 3 C 2 T x The solution was sonicated for 10 minutes, 2.5 mL of 10 mg / mL chloroplatinic acid was added, and after 10 minutes of sonication, it was continuously reduced for 24 hours under the protection of nitrogen. The product was centrifuged at 9500 rpm for 10 min, washed with ethanol and lyophilized. The lyophilized product was formulated into a 0.5 mg / mL solution to obtain PtNP@MXene-Ti 3 C 2 T x nanocomposites.

[0071] (2) Surface pretreatment of the working electrode. The glassy carbon electrode was polished to a mirror surface on a polishing cloth with 0.3 μm and 0.05 μm alumina powder in turn, rinsed with ultrapure water, and dried with nitrogen to obtain a pretreated glassy carbon electrode.

[0072] (3) The modification process of the working electrode is as follows: fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com