Process application method of low-grade phosphorite in hot-process phosphorus chemical industry

A process application, low-grade technology, applied in the chemical industry, phosphate material processing, sustainable manufacturing/processing, etc., can solve the problem that low-grade phosphate rock cannot be used, and achieve good flotation effect, high content, and improved mineral processing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

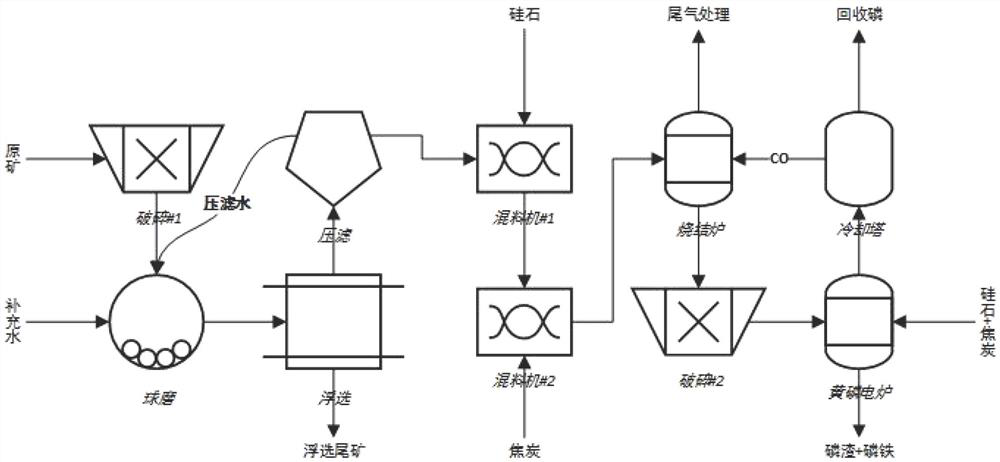

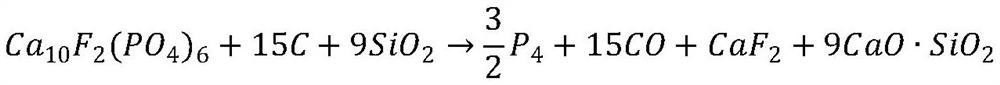

Method used

Image

Examples

Embodiment 1

[0048] Raw materials: 100kg of phosphate rock, of which P 2 o 5 content of 19.88%, MgO content of 1.25%, SiO 2 content of 36.87%, CaO content of 28.98%, Fe 2 o 3 The content is 1.75%, Al 2 o 3 The content is 2.32%, CO 2 The content is 3.88%, and the lump ore is ground to a particle size of less than 0.074mm by crushing and wet grinding, accounting for 80%.

[0049] Step 1: Add flotation agents in the flotation machine (pH regulator sodium carbonate 300g, collector TG 150g, inhibitor sodium silicate 400g, desiliconization main synergist LR 80g, desilication auxiliary synergist MR 30g ) for positive flotation to obtain flotation concentrate, where P 2 o 5 The content is 24.11%, SiO 2 content of 25.53%, CaO content of 38.26%, CO 2 The content is 4.25%, and the concentrate yield of positive flotation is about 71% (that is, 100kg raw ore gets 71kg concentrate);

[0050] Step 2: The flotation concentrate is obtained by pressure filtration with a water content of 8% and a ...

Embodiment 2

[0058] Raw materials: 100kg of phosphate rock, of which P 2 o 5 content of 19.88%, MgO content of 1.25%, SiO 2 content of 36.87%, CaO content of 28.98%, Fe 2 o 3 The content is 1.75%, Al 2 o 3 The content is 2.32%, CO 2 The content is 3.88%, and the lump ore is ground to a particle size of less than 0.074mm by crushing and wet grinding, accounting for 90%.

[0059] Step 1: add flotation agents (pH regulator 550g, collector 220g, inhibitor 495g, desiliconization main synergist 121g, desilication auxiliary synergist 33g) in the flotation machine to carry out positive flotation to obtain flotation Concentrate, where P 2 o 5 The content is 24.89%, SiO 2 content of 22.46%, CaO content of 39.87%, CO 2 The content is 4.12%, and the concentrate yield of positive flotation is about 67% (that is, 100kg raw ore gets 67kg concentrate);

[0060] Step 2: The flotation concentrate is obtained by pressure filtration with a water content of 8% and a quality of about 73kg;

[0061] ...

Embodiment 3

[0068] Raw materials: 100kg of phosphate rock, of which P 2 o 5 content of 19.88%, MgO content of 1.25%, SiO 2 content of 36.87%, CaO content of 28.98%, Fe 2 o 3 The content is 1.75%, Al 2 o 3 The content is 2.32%, CO 2 The content is 3.88%, and the lump ore is ground to a particle size of less than 0.074mm by crushing and wet grinding, accounting for 80%.

[0069] Step 1: add flotation agents (pH regulator 550g, collector 220g, inhibitor 495g, desiliconization main synergist 121g, desilication auxiliary synergist 33g) in the flotation machine to carry out positive flotation to obtain flotation Concentrate, where P 2 o 5 The content is 24.53%, SiO 2 content of 24.20%, CaO content of 38.93%, CO 2 The content is 4.32%, and the concentrate yield of positive flotation is about 69% (that is, 100kg raw ore gets 69kg concentrate);

[0070] Step 2: The flotation concentrate is obtained by pressure filtration with a water content of 8% and a quality of about 75kg;

[0071] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Ability to withstand stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com