A method for removing iron and cyanide by mixing copper-containing wastewater and cyanide-containing wastewater

A technology for removing iron, cyanide and cyanide wastewater, applied in the fields of environmental protection and metallurgy, can solve problems such as failure to meet discharge standards, and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

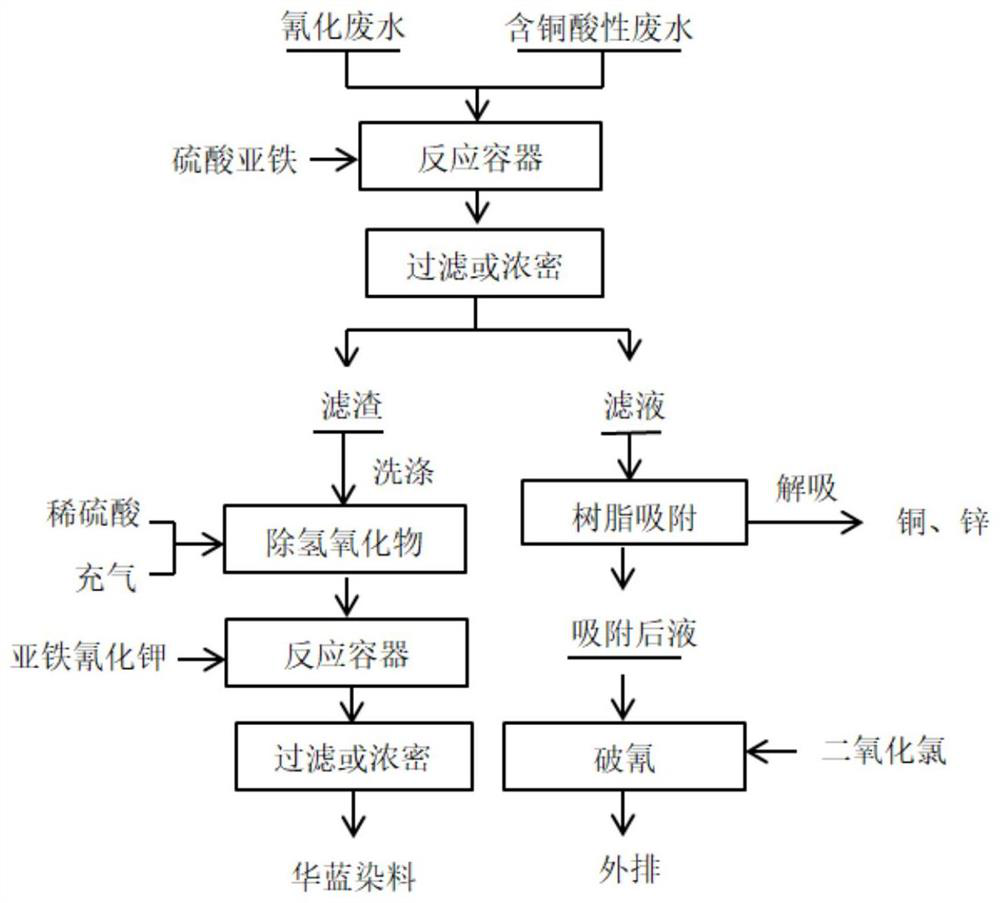

[0027] The present embodiment provides a method for removing iron and cyanide by mixing copper-containing wastewater and cyanide-containing wastewater, which specifically includes the following steps:

[0028] S1. In a closed reaction tank, sulfuric acid, Cu 2+ Ion, Fe 3+ Ions and Zn 2+ ionic copper-containing acidic wastewater with sodium hydroxide and CN - The ionized cyanide-containing wastewater is mixed for neutralization, CN - with Fe 3+ The mass ratio is not greater than 2.1, and ferrous sulfate is added, CN - with Fe 2+ The mass ratio is not greater than 2.8, and the pH is controlled between 3.0-5.5; the reaction is carried out for 1h;

[0029] Specifically, pH can be monitored by an online pH detector;

[0030] In addition, hydrogen cyanide can be monitored online with an online hydrogen cyanide monitor.

[0031] S2, press 2g / m to the post-reaction liquid obtained in step S1 3 The proportion of polyacrylamide with a mass concentration of 1‰ was added to carry...

Embodiment 2

[0036] In a gold mine in Fujian, the copper-containing acid wastewater contains about 10g / L of sulfuric acid, 80-100mg / L of copper ions, and 0.25-0.35g / L of zinc ions. The total iron content (mainly ferric ions) varies with seasons. Fluctuates between 8-12g / L, and iron is mainly composed of Fe in copper-containing acidic wastewater 2 (SO 4 ) 3 form exists. The cyanide content in the cyanide-containing wastewater is about 200mg / L, and the sodium hydroxide content is about 2g / L.

[0037] (1) Analysis of the existing process

[0038] The existing treatment process of copper-containing acid wastewater is two-stage neutralization, and the daily water treatment volume is 4000m3 3 In terms of / d, the cost of water treatment per ton is 20-25 yuan. Cyanide-containing wastewater according to the treatment volume of 20000m 3 / d calculation, the processing cost is 20-25 yuan / ton.

[0039] Specifically, the existing two-stage neutralization treatment process reaction principle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com