PZT-based high-Curie-temperature piezoelectric ceramic and preparation method thereof

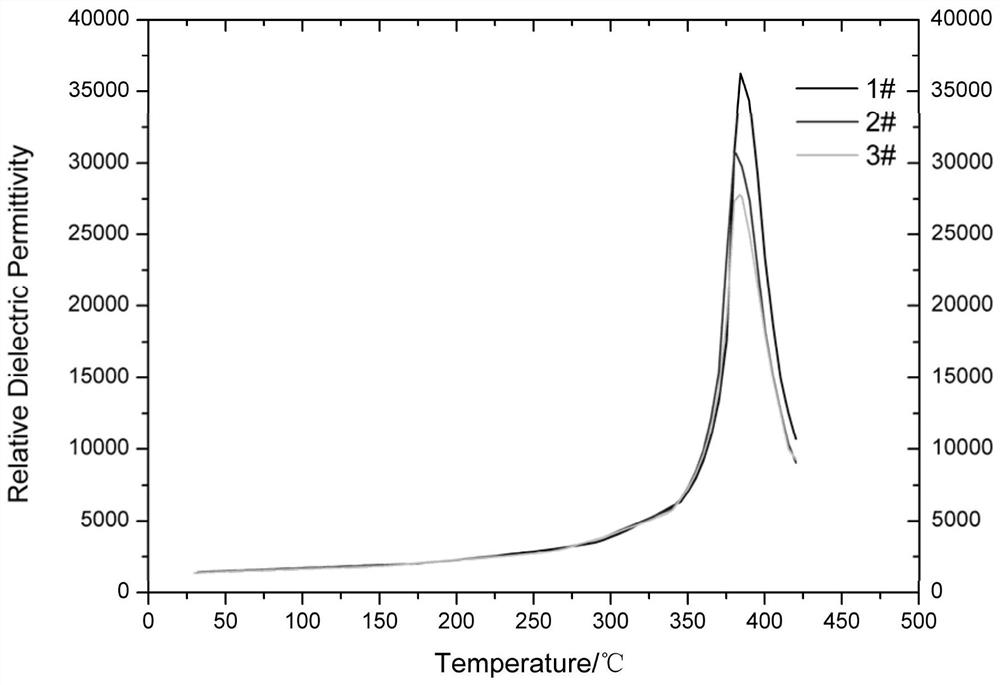

A piezoelectric ceramic, lead tetroxide technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problems of loss of piezoelectric performance, reduction of gasoline consumption rate, degradation of piezoelectric ceramic performance, etc. The comprehensive electrical performance is good, the Curie temperature is increased, and the Curie temperature is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The invention discloses a preparation method of a PZT-based high Curie temperature piezoelectric ceramic, which comprises the following preparation steps:

[0027] 1) LiNb0 3 Synthesis: Baking lithium carbonate and niobium pentoxide at a temperature of 120-130°C for 12 hours, then dry mixing and ball milling, and keeping the uniformly mixed materials at a temperature of 1000-1100°C for 4 hours to synthesize LiNb0 3 ;

[0028] 2) Mixing: the synthesized LiNb0 3 , three lead tetroxide, zirconium dioxide and titanium dioxide were added to the drum mill for wet mixing for 18 hours, and the slurry was produced after fully mixing;

[0029] 3) Pre-firing: Dry the mixed slurry, put it in an alumina crucible after briquetting, and then carry out pre-firing synthesis in a tunnel-type pusher kiln.

[0030] 4) Granulation: crush the pre-burned material, and then place it in a stirring mill for fine grinding. When stirring, the weight ratio of raw materials: zirconium balls: pure...

Embodiment 1

[0037] 1) LiNb0 3 Synthesis: Baking 0.10 parts by weight of lithium carbonate and 2.11 parts by weight of niobium pentoxide at a temperature of 120-130°C for 12 hours, then dry mixing and ball milling, and keeping the uniformly mixed materials at a temperature of 1000-1100°C for 4 hours. Synthesis of LiNb0 3 ;

[0038] 2) Mixing: the synthesized LiNb0 3 , 100 parts by weight of PbO4, 27.54 parts by weight of zirconium dioxide, and 16.26 parts by weight of titanium dioxide were added to the drum mill for wet mixing for 18 hours, fully mixed and then discharged;

[0039] 3) Pre-firing: Dry the mixed slurry, put it in an alumina crucible after briquetting, and then carry out pre-firing synthesis in a tunnel-type pusher kiln.

[0040] 4) Granulation: Pulverize the pre-burned material block, then place it in a stirring mill for fine grinding, and mix according to the weight ratio of raw materials:

[0041] Zirconium balls: pure water = 1:2:0.7 ratio, after stirring for 3 hours,...

Embodiment 2

[0051] 1) LiNb0 3 Synthesis: Baking 0.12 parts by weight of lithium carbonate and 2.33 parts by weight of niobium pentoxide at a temperature of 120-130°C for 12 hours, then dry mixing and ball milling, and keeping the uniformly mixed materials at a temperature of 1000-1100°C for 4 hours. Synthesis of LiNb0 3 ;

[0052] 2) Mixing: the synthesized LiNb0 3 100 parts by weight of trilead tetraoxide, 27.27 parts by weight of zirconium dioxide, 16.26 parts by weight of titanium dioxide, and 0.01 parts by weight of antimony trioxide were added to the drum mill for wet mixing for 18 hours, and the pulp was discharged after fully mixing;

[0053] Steps 3)-9) are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com