Formula and preparation method of water-based self-extinction polyurethane leather finishing agent

A polyurethane leather and self-dulling technology, which is applied in the preparation of water-based self-dulling polyurethane leather finishing agents, and in the field of water-based self-dulling polyurethane leather finishing agents, can solve the problems of unstable matting properties of product batches, insufficient matting degree, and brightening of matting coatings, etc. problem, to achieve the effect of good reproducibility in workshop production, adjustable extinction degree, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

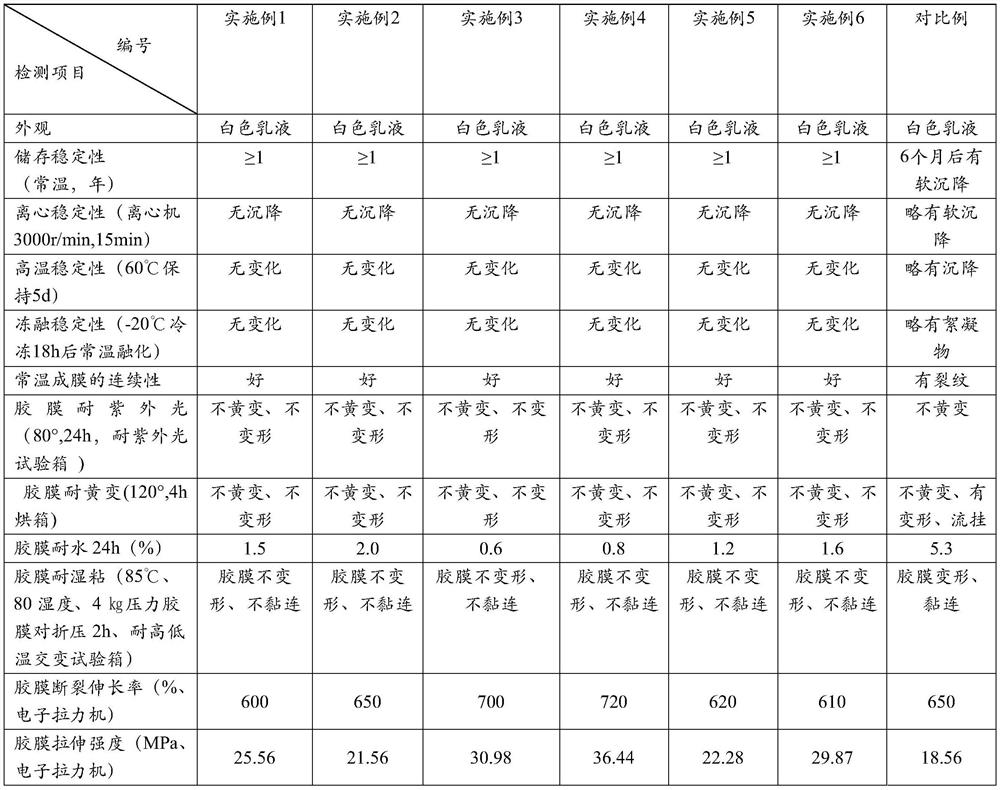

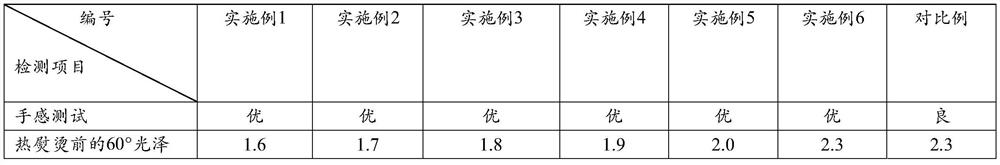

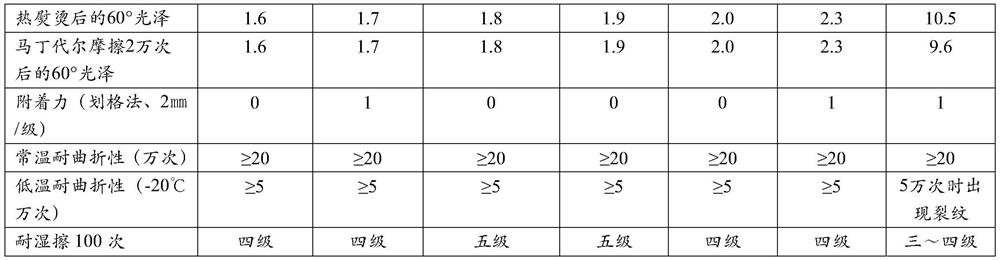

Examples

Embodiment 1

[0046] The formula of water-based self-dulling polyurethane leather finishing agent comprises the following components in parts by weight:

[0047] Polytetrahydrofuran ether diol (M=250): 14.0 parts, polytetrahydrofuran ether diol (M=3000): 175 parts, isophorone diisocyanate (IPDI): 46.6 parts, hexamethylene diisocyanate (HDI) : 10 parts, U.S. Ventellus organic bismuth catalyst 83AC-83: 0.06893 parts, dimethylolbutyric acid (DMBA): 4.4 parts, 1,6-hexanediol (1.6-HDO): 0 parts, dimethylaminoethanol (DMEA): 2.6 parts, German BASF anti Oxygen agent Irganox 1010: 1.0 parts, German BASF UV absorber TINUVIN 329: 2.0 parts, methyl acetate: 70 parts, Eastman cellulose acetate butyrate CAB-381-0.1: 2.0 parts, deionized water: 620 parts, German Lauritan special reaction type hydroxy alcohol alkoxylate compound FT-625: 3.0 parts, ethylenediamine: 6.0 parts, Guangzhou Zungan Synthetic Materials Co., Ltd. modified silicone ZH-505: 3.0 parts, Hemingster Dechem RHEOLATE 175 hydrophobicall...

Embodiment 2

[0059] The formula of water-based self-dulling polyurethane leather finishing agent comprises the following components in parts by weight:

[0060] Polyoxypropylene diol (M=400): 13.0 parts, Polyoxypropylene diol (M=4000): 178.1 parts, Isophorone diisocyanate (IPDI): 44.0 parts, Hexamethylene diisocyanate (HDI) : 8.3 parts, American Ventrus organic bismuth catalyst 83AC-83: 0.1379 parts, dimethylol butyric acid (DMBA): 4.6 parts, 1.6-hexanediol (1.6-HDO): 2.0 parts, dimethylaminoethanol (DMEA): 2.8 parts, German BASF antioxidant Irganox 1010: 1.2 parts, German BASF UV absorber TINUVIN 329: 1.8 parts, methyl acetate: 80 parts, Eastman cellulose acetate butyrate CAB-381-0.1: 2.1 parts, deionized water: 637 parts, German labor Ritan special reaction type hydroxy alcohol alkoxy compound FT-625: 3.2 parts, hexamethylenediamine: 12.0 parts, modified silicone ZH-505 of Guangzhou Zungan Synthetic Materials Co., Ltd.: 3.2 parts, RHEOLATE175 of Hemingster Deqian Hydrophobically modif...

Embodiment 3

[0072] The formula of water-based self-dulling polyurethane leather finishing agent comprises the following components in parts by weight:

[0073] Polytetrahydrofuran ether diol (M=250): 12.0 parts, Jiangsu Yixing Xingning Chemical Polypropylene Carbonate Diol PPC-3A-1 (M=3000): 177.1 parts, isophorone diisocyanate (IPDI): 40.0 parts, hexamethylene diisocyanate (HDI): 15.0 parts, Belgian Umicore UMICORE organic bismuth catalyst Bi1010: 0.1838 parts, dimethylol butyric acid (DMBA): 4.9 parts, 1.6-hexanediol (1.6-HDO ): 1.0 parts, dimethylaminopropanol (AMP-95): 2.9 parts, German BASF antioxidant Irganox 1010: 1.4 parts, German BASF ultraviolet absorber TINUVIN 329: 1.6 parts, methyl acetate: 85 parts, Yishi Cellulose acetate butyrate CAB-381-0.1: 2.2 parts, deionized water: 643 parts, German Lauritan special reaction type hydroxyl alcohol alkoxylate compound FT-625: 3.4 parts, isophorone diamine: 15.0 parts Parts, modified silicone ZH-505 of Guangzhou Zungan Synthetic Materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com