Anti-freezing viscous flame-retardant conductive polymer gel as well as preparation method and application thereof

A conductive polymer and gel technology, which is applied in conductive materials, conductive materials, circuits, etc., can solve the problems of molecular chain movement, intermolecular interaction obstacles, gel self-repair difficulties, etc., to improve mechanical properties and easily self-repair , Good self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] A preparation method of antifreeze viscous flame-retardant conductive polymer gel, comprising the following steps:

[0040] (1) dissolving acrylamide monomer and imidazole monomer in a solvent, then adding an initiator, and reacting at 50-80°C for 20-30 minutes to obtain a viscous solution;

[0041] (2) adding conductive polymer monomer or salt thereof to the viscous solution of step (1);

[0042] (3) Then add the iron salt into the solution of (2), stir vigorously for 3-5 minutes to obtain a pre-gel, and leave the pre-gel for more than 3 hours to obtain the final conductive polymer gel.

Embodiment 1

[0045] A kind of antifreeze viscous flame-retardant conductive polymer gel, prepared from the following raw materials in mass percentage: water 50%, acrylamide monomer 10%, 1-allyl-3-methyl imidazole chloride 5%, aniline 15% % and ferric chloride 19.5% and ammonium persulfate 0.5%.

[0046] A preparation method of antifreeze viscous flame-retardant conductive polymer gel, comprising the following steps:

[0047] (1) dissolving acrylamide monomer and imidazole monomer in a solvent, then adding ammonium persulfate, and reacting at 60° C. for 20 minutes to obtain a viscous solution;

[0048] (2) adding aniline to the viscous solution of step (1);

[0049] (3) Then add ferric chloride into the solution of (2), stir vigorously for 3 minutes to obtain a pre-gel, and leave the pre-gel for more than 3 hours to obtain the final conductive polymer gel.

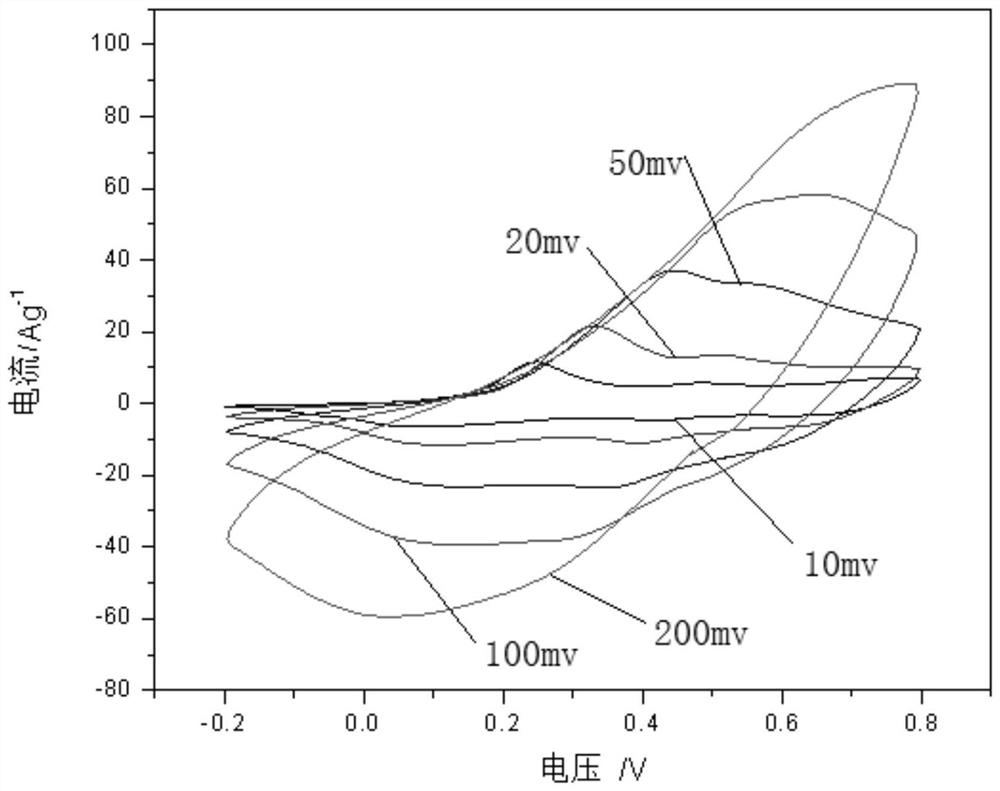

[0050] The conductive polymer gel prepared in Example 1 is tested by cyclic voltammetry, and the CV curve of the conductive polymer ...

Embodiment 2

[0056] A kind of antifreeze viscous flame-retardant conductive polymer gel, prepared from the following raw materials in mass percentage: solvent 45%, acrylamide monomer 15%, 1-allyl imidazole 5%, pyrrole 14.9%, iron sulfate 20% and Potassium persulfate 0.1%, the solvent is a mixed solution of water and ethylene glycol, the volume ratio of water and ethylene glycol is 1:1.

[0057] The preparation method of the antifreeze viscous flame-retardant conductive polymer gel comprises the following steps:

[0058] (1) dissolving acrylamide monomer and imidazole monomer in a solvent, then adding potassium persulfate, and reacting at 50°C for 30 minutes to obtain a viscous solution;

[0059] (2) pyrrole is added in the viscous solution of step (1);

[0060] (3) Then add ferric sulfate into the solution of (2), stir vigorously for 5 minutes to obtain a pre-gel, and leave the pre-gel for more than 3 hours to obtain the final conductive polymer gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com