Crystallizer copper pipe drawing oil containing sulfurization modified illegal cooking oil

A crystallizer copper tube and gutter oil technology, which is applied in the petroleum industry, process efficiency improvement, fatty substance recovery, etc., can solve the problem of high cost of use, achieve the effect of reducing consumption, reducing cost of use, and relieving environmental pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

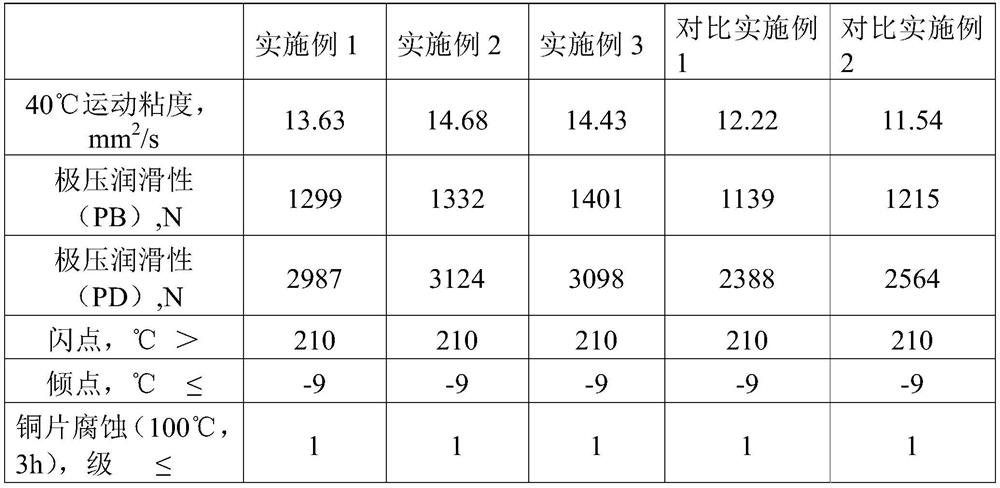

Examples

Embodiment 1

[0015] A kind of crystallizer copper pipe drawing oil containing vulcanized modified waste oil, comprising the following components by weight: 30 parts of vulcanized modified waste oil, 40 parts of base oil, 0.1 part of metal deactivator, 0.5 part of antioxidant, 1 part of adhesive; the base oil is a homogeneous mixture of isoparaffin solvent oil and polyisobutylene with a molecular weight of 500-1000, and the mass ratio of the two is 1:2.

[0016] Sulfurized modified waste oil is prepared by the following steps:

[0017] Step 1, the waste oil (acid value 2.99mg / gKOH, saponification value 191.02mg / gKOH, peroxygen value 29.3mmol / kg, iodine value 93gI / 100g) collected from Beijing will be collected after dewatering and impurity removal, at 150 Heat and stir at ~170°C for 1 hour, then lower the temperature to 100°C, add activated clay to it, heat and stir for 0.5 hour, and then centrifuge to obtain refined waste oil;

[0018] Step 2: Stir and heat the refined sewer and ethylenedi...

Embodiment 2

[0022] A kind of crystallizer copper pipe drawing oil containing vulcanized modified waste oil, comprising the following components by weight: 60 parts of vulcanized modified waste oil, 25 parts of base oil, 0.3 part of metal deactivator, 0.3 part of antioxidant, 5 parts of viscose; The base oil is isoparaffin solvent oil.

[0023] Sulfurized modified waste oil is prepared by the following steps:

[0024] Step 1, after the waste oil (acid value 15.01mg / gKOH, saponification value 188.33mg / gKOH, peroxide value 27.4mmol / kg, iodine value 98.67gI / 100g) collected from Qingdao is removed from water and impurities, in Heat and stir at 170-200°C for 1 hour, then cool down to 100°C, add activated clay to it, heat and stir for 2 hours, and then centrifuge to obtain refined waste oil;

[0025] Step 2: Stir and heat the refined sewer and ethylenediamine prepared in Step 2 under a nitrogen atmosphere until they are evenly mixed, then add elemental sulfur in batches, continue to heat up to ...

Embodiment 3

[0029] A kind of crystallizer copper pipe drawing oil containing vulcanized modified waste oil, comprising the following components by weight: 45 parts of vulcanized modified waste oil, 38 parts of base oil, 0.3 part of metal deactivator, 0.3 part of antioxidant, 5 parts of viscose; The base oil is isoparaffin solvent oil.

[0030] Sulfurized modified waste oil is prepared by the following steps:

[0031] Step 1, the waste oil (acid value 33.21mg / gKOH, saponification value 188.96mg / gKOH, peroxygen value 22.5mmol / kg, iodine value 77gI / 100g) collected from Inner Mongolia will be collected after dewatering and impurity removal, at 170 Heat and stir at ~200°C for 1 hour, then lower the temperature to 100°C, add activated clay to it, heat and stir for 2 hours, and then centrifuge to obtain refined waste oil;

[0032] Step 2: Stir and heat the refined sewer and ethylenediamine prepared in Step 2 under a nitrogen atmosphere until they are evenly mixed, then add elemental sulfur in b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com