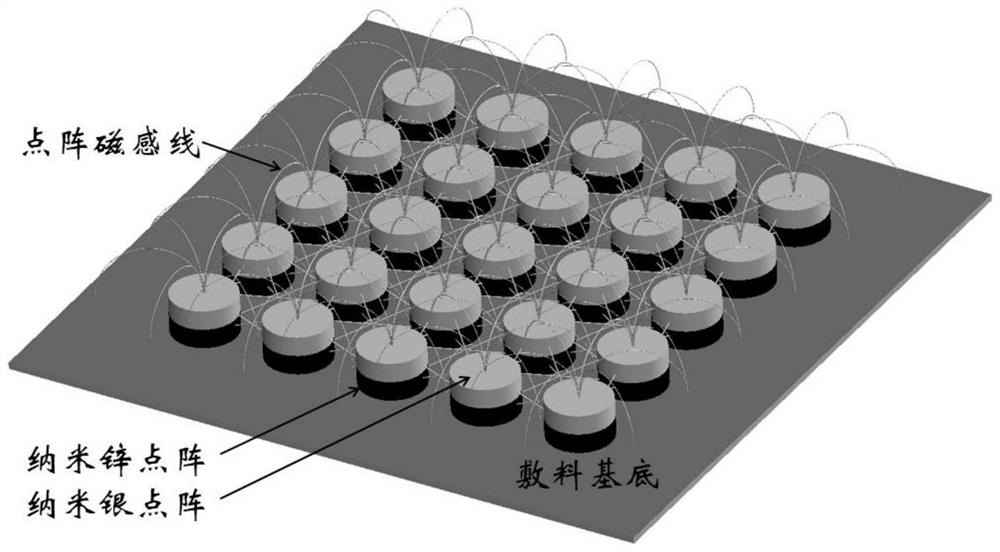

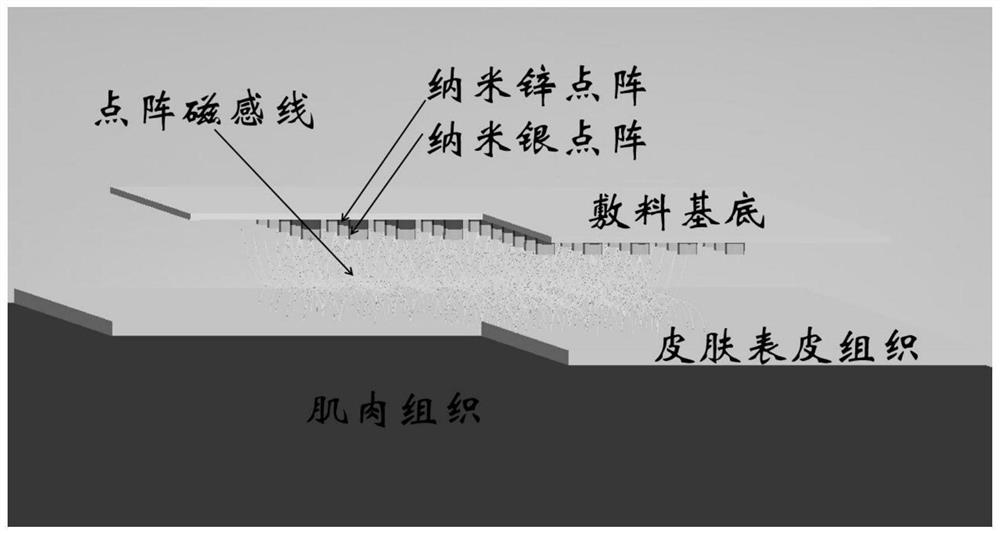

A kind of preparation method of nano ag-zn double-layer lattice coating

A lattice and coating technology, which is applied in the field of preparation of nano-Ag-Zn double-layer lattice coatings, can solve the problems of unrecorded coating materials for the recovery of damaged tissue cells, and achieve the goal of not being easy to adhere and grow, Promotes wound healing and avoids highly toxic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

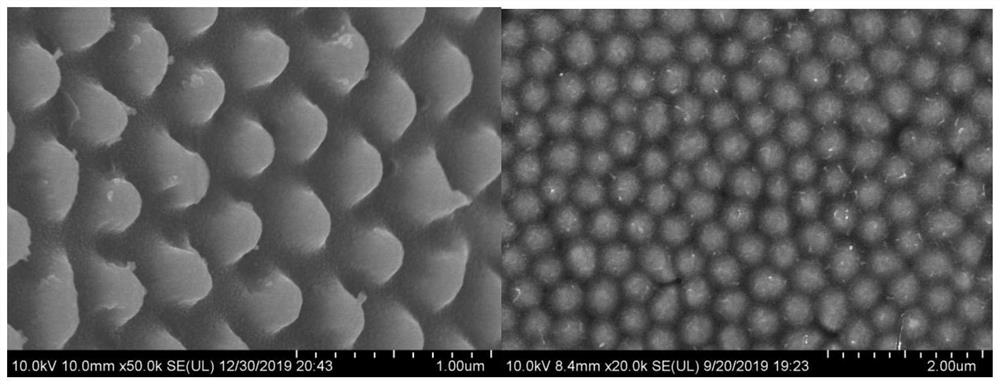

[0037]Embodiment 1: a kind of preparation method of nanometer Ag-Zn double-layer lattice coating, this method comprises the following steps:

[0038] (1) Surface treatment of monocrystalline silicon substrate. Select a single crystal silicon substrate with a size of 10mm*10mm, place the substrate in a concentrated sulfuric acid solution, and use an ultrasonic cleaner to clean it for 10 minutes. After taking out the substrate, rinse it with deionized water and then put it into deionized water for ultrasonic cleaning for 10 minutes. Take out the substrate again and dry it in nitrogen gas. Bake in the oven to remove moisture and static electricity on the surface of the substrate;

[0039] (2) Ultrathin AAO template transfer. After the single crystal silicon substrate is cleaned, a porous anodic aluminum oxide film (AAO) is prepared, with a size of 260nm in diameter, 450nm in spacing, and 200nm in thickness. Slowly spread the polymethacrylate supporting layer (PMMA) auxiliary ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com