A kind of preparation method of superhydrophobic filter net of growing boron nitride nano-coral on the surface

A technology of surface growth and boron nitride, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve problems such as difficult cleaning, high operating costs, membrane pollution, etc., and achieve reduced mesh size, good adsorption performance, The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment includes the following steps:

[0042] Step 1. After mixing boron oxide and iron powder according to the molar ratio of 1:1, use a planetary ball mill in a nitrogen protective atmosphere to carry out ball milling treatment for 4 hours in the forward and reverse alternate operation mode to obtain ball milling powder; the ball milling powder The particle size is 2μm~10μm;

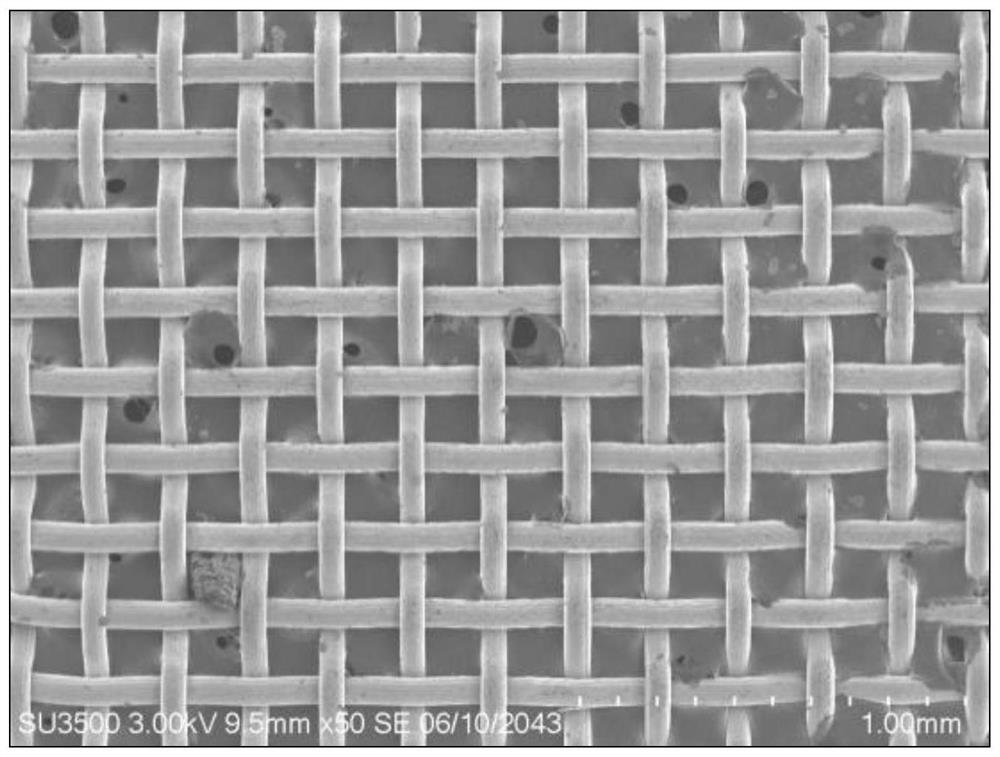

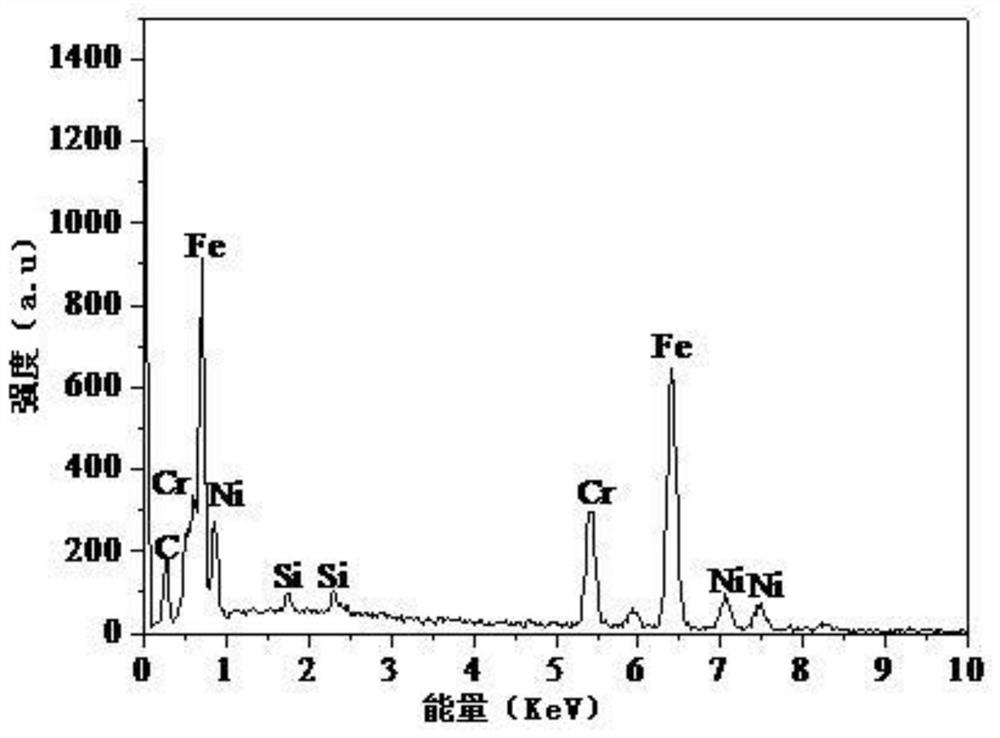

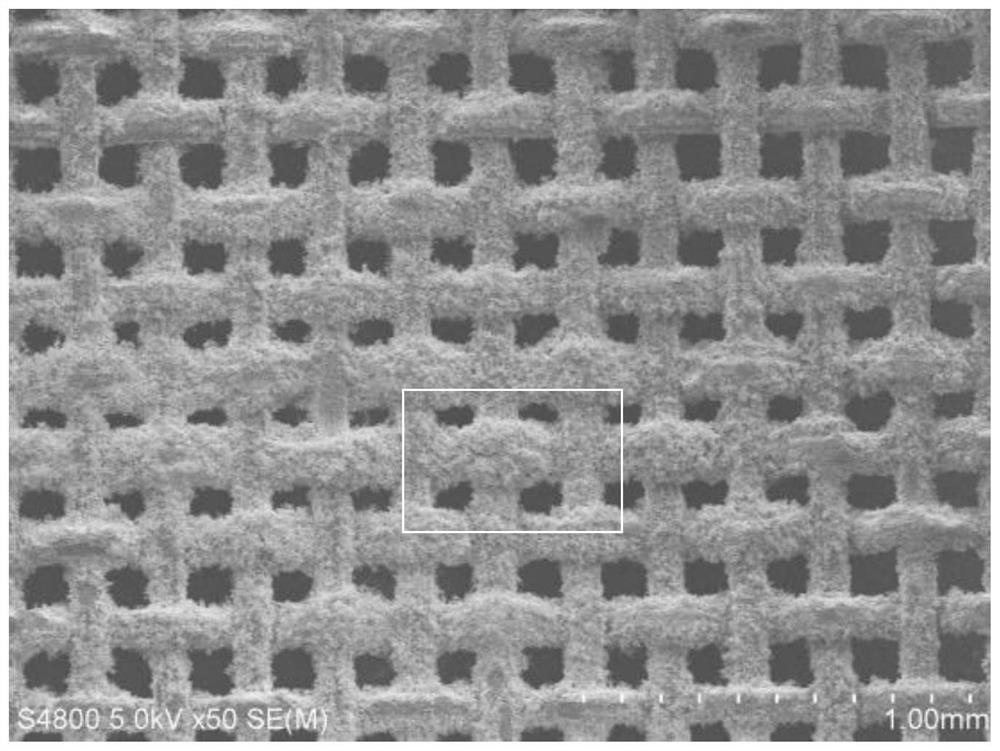

[0043] Step 2, place the ball mill powder obtained in step 1 in a square porcelain boat, then place a 30mm×30mm (length×width) stainless steel wire mesh on the upper center of the square porcelain boat for annealing treatment, and deposit nitrogen on the stainless steel wire mesh boron nitride nano-coral, obtain the superhydrophobic filter net of boron nitride nano-coral growing on the surface; the area of the stainless steel wire mesh is less than the area of the square porcelain boat; the process of the annealing treatment is: first pass into Argon protective atmosphere, in the a...

Embodiment 2

[0066] The difference between this embodiment and embodiment 1 is: the time of heat preservation in step 2 is 2h.

[0067] After testing, a large number of dense boron nitride nano-corals grew on the surface of the super-hydrophobic filter prepared in this example, and the contact angle between the super-hydrophobic filter and water droplets was as high as 166°.

Embodiment 3

[0069] The difference between this embodiment and embodiment 1 is: the time of heat preservation in step 2 is 6h.

[0070] After testing, a large number of dense boron nitride nano-corals grew on the surface of the super-hydrophobic filter prepared in this example, and the contact angle between the super-hydrophobic filter and water droplets was as high as 170°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com