Energy-saving efficient semi-gasification warm air furnace

A heater and semi-gasification technology, applied in the field of energy-saving and high-efficiency semi-gasification heaters, can solve the problems of high energy efficiency waste, small heat dissipation area, insufficient combustion, etc. The effect of speeding up the heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The warm air stove is a stove used for indoor heating, kang heating and cooking. It is an outer cover with a steel plate fixed on the ordinary cast iron furnace, forming a space layer with the furnace body, that is, the hot air chamber. The hot air chamber is connected to the external cold air inlet, and the upper part has a warm air outlet. The furnace body radiates heat while increasing the directional warm air heating.

[0030] Traditional heaters have problems such as insufficient combustion, serious black smoke pollution, and low thermal efficiency; and the use of single heat radiation for heat dissipation, small heat dissipation area, slow heat dissipation speed, and high energy efficiency waste.

[0031] In view of the above problems, the present invention provides an energy-saving and high-efficiency semi-gasification heater.

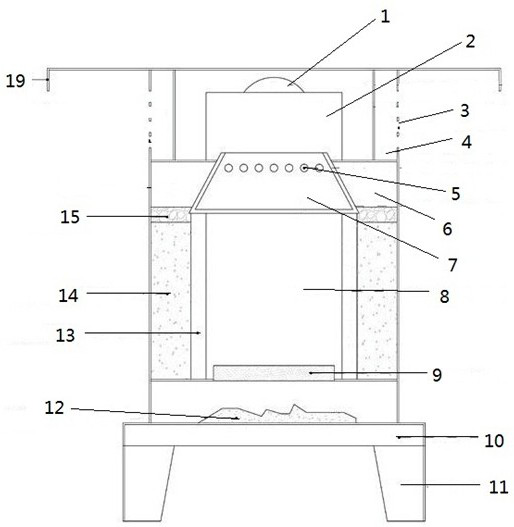

[0032] Specific as Figure 1~4 As shown, an energy-saving and high-efficiency semi-gasification heater includes a furnace 8 installed ...

Embodiment 2

[0040] The embodiment of the present invention is further limited on the basis of embodiment 1.

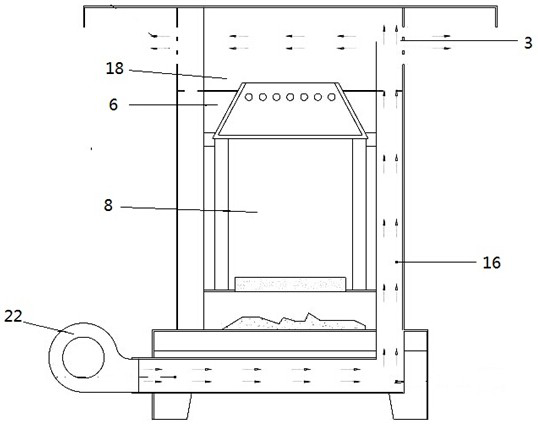

[0041] Such as Figure 1~3 As shown, a thermal insulation layer 14 is provided between the outside of the furnace 8 and the shell of the furnace body, and the thermal insulation layer 14 is a perlite thermal insulation layer, and the top of the thermal insulation layer 14 is provided with a pouring layer 15, and the pouring layer 15 is the pouring layer of refractory material.

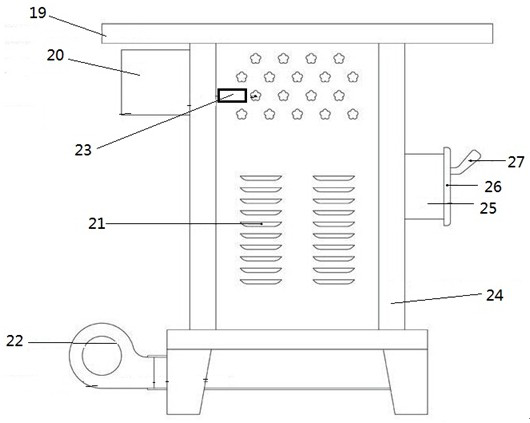

[0042] The furnace 8 is equipped with a casting grate 9 at the bottom, and the lower side of the casting grate 9 is furnace ash 12, and a chimney 20 is arranged on the top of the furnace 8, and the chimney 20 communicates with the furnace 8 through the chimney mouth 1, and at the chimney mouth 1 The side is provided with windshield 2.

[0043] The furnace 8 is provided with a charging port 25, and the charging port 25 is provided with a furnace door 26, and a switch handle 27 is installed on the furnace ...

Embodiment 3

[0046] The embodiment of the present invention is further limited on the basis of embodiment 1 and embodiment 2.

[0047] Such as figure 1 As shown, a furnace surface 19 is installed on the top of the furnace body shell, and a base 10 is installed at the bottom of the furnace body shell, and a furnace leg 11 is installed at the bottom of the base 10 .

[0048] The working principle of the present invention is: the energy-saving and high-efficiency semi-gasified air heater of the present invention, during the working process of the fan I 22, 23, accelerates the air circulation and air convection speed, and realizes gas convection heating; combined with the heat radiation and heat dissipation of the furnace body itself, two kinds of heating The combination of methods greatly increases the heating area and accelerates the heating speed; the furnace 8 adopts the louver air inlet hole 21 or the furnace body air inlet channel 24 for secondary oxygen distribution, so that the combust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com