Preparation method of Ni/Co-CNT/NHPC lithium-sulfur battery positive electrode material

A lithium-sulfur battery and cathode material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve problems such as low specific capacity, achieve strong chemical adsorption and physical adsorption, high specific surface area, and good conductivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

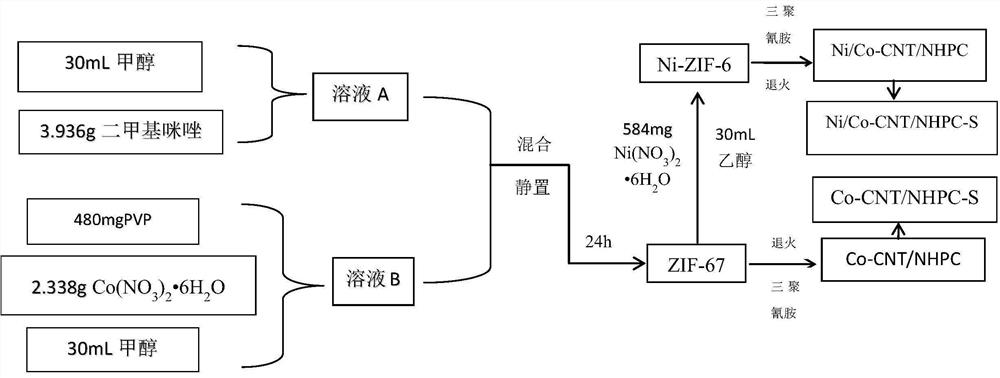

[0042] Step 1. Prepare the precursor solution: disperse 480mg PVP in 30mL methanol solution, sonicate for 1h, then add 0.1mmol Co(NO 3 ) 2 ·6H 2 O, stirred magnetically at room temperature for 1 h to obtain solution A, dispersed 0.1 mmol dimethylimidazole in 30 mL of methanol solution, and stirred magnetically at room temperature for 1 h to obtain solution B. Then quickly pour solution A into solution B, stir magnetically at room temperature for 20 minutes to prepare the precursor solution;

[0043] Step 2. Preparation of ZIF-67: Seal the above-mentioned precursor solution with a parafilm and let it stand at room temperature for 24 hours, then centrifuge at 10,000 r / min for 10 minutes, and then wash with ethanol and deionized water to obtain ZIF-67 The product was dried under vacuum at 75°C for 12 hours;

[0044] Step 3, preparation of Ni-ZIF67: disperse 200mg ZIF-67 powder in ethanol, stir for 30min, add 0.1mmol of Ni(NO 3)2 ·6H 2 O, continue stirring for 40 min, then ce...

Embodiment 2

[0048] Step 1, preparation of precursor solution: same as Step 1 in Example 1;

[0049] Step 2. Preparation of ZIF-67: same as Step 2 in Example 1;

[0050] Step 3, preparation of Ni-ZIF67: same as Step 3 in Example 1;

[0051] Step 4, annealing: mechanically mix 200mg of Ni-ZIF-67 with 1g of melamine powder, fully grind, and place the final products in a tube furnace respectively, 2 / Under Ar atmosphere, heat at 2°C / min to 250°C for 1h, 800°C for 2h, then cool to room temperature;

[0052] Step 5, pickling: same as Step 5 in Example 1.

Embodiment 3

[0054] Step 1, preparation of precursor solution: same as Step 1 in Example 1;

[0055] Step 2. Preparation of ZIF-67: same as Step 2 in Example 1;

[0056] Step 3, preparation of Ni / Zn-ZIF67: same as Step 3 in Example 1;

[0057] Step 4, annealing: mechanically mix 200mg of Ni-ZIF-67 and 1.2g of melamine powder, fully grind, and place the final products in a tube furnace respectively, 2 / Under Ar atmosphere, heat at 2°C / min to 250°C for 1 hour, 800°C for 2h, then cool to room temperature;

[0058] Step 5, pickling: same as Step 5 in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com