CsPbI3 mixed-phase perovskite thin film and controllable preparation method thereof

A perovskite and thin film technology, which is applied in the field of CsPbI3 mixed-phase perovskite thin film and its controllable preparation, can solve difficult problems and achieve the effect of easy implementation, simple method and novel materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

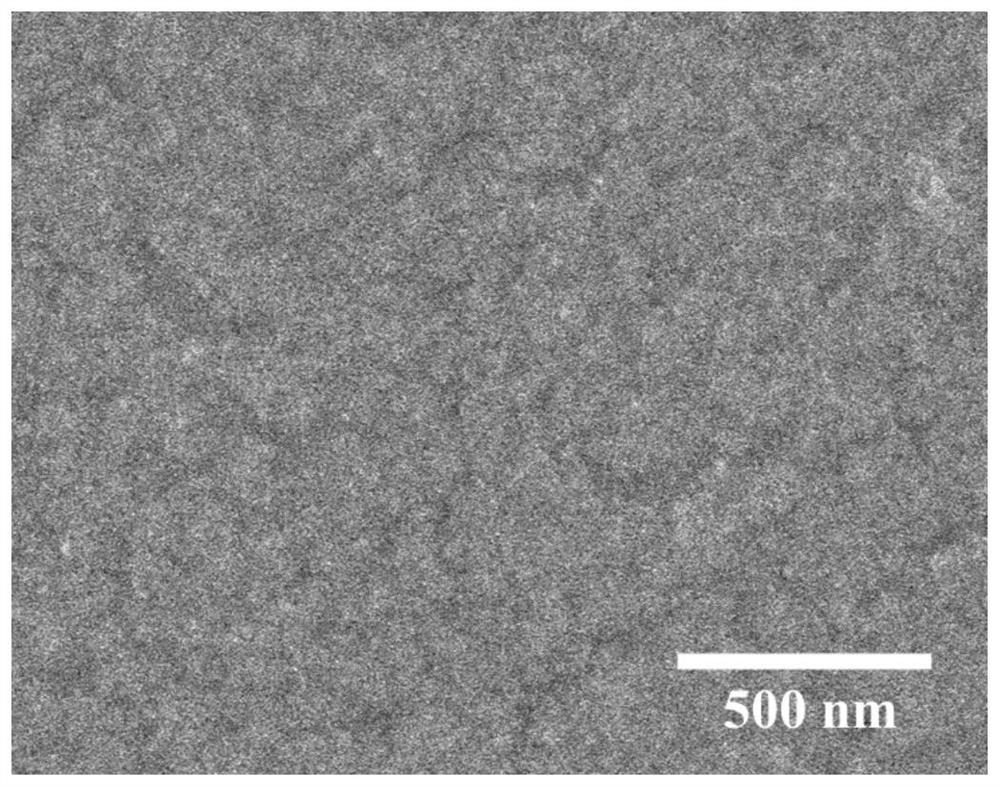

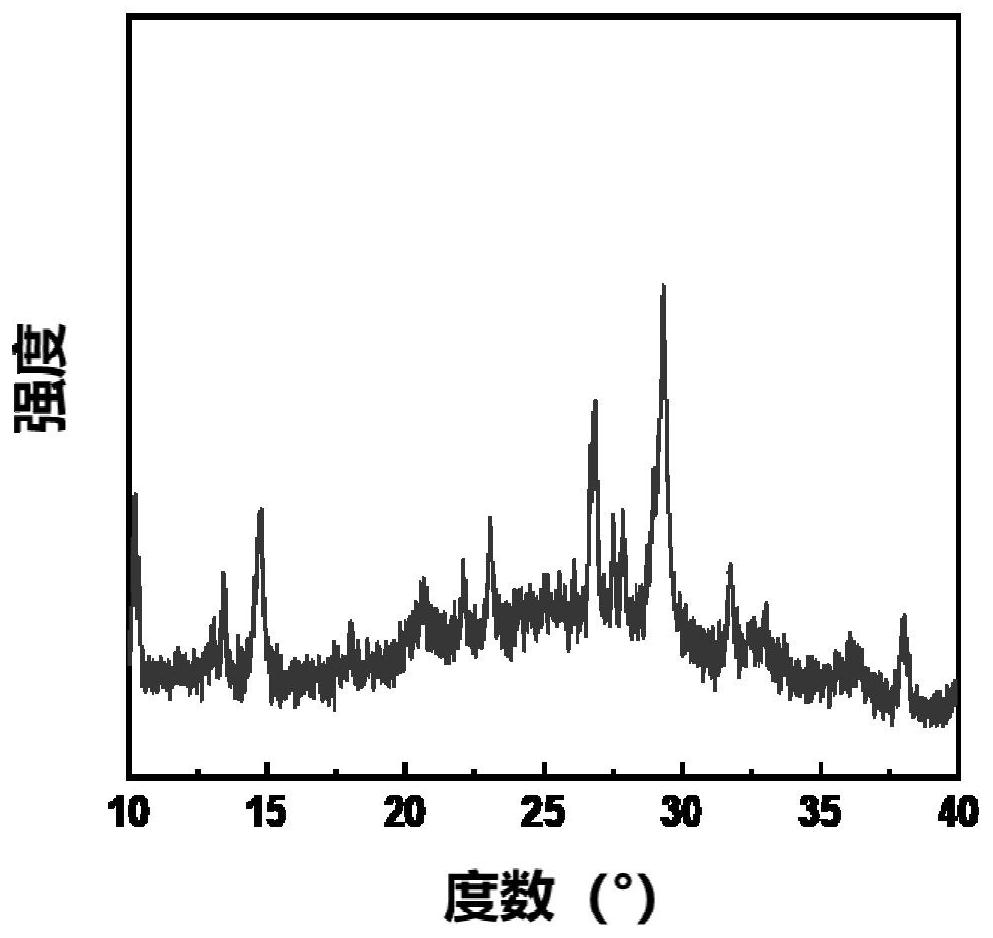

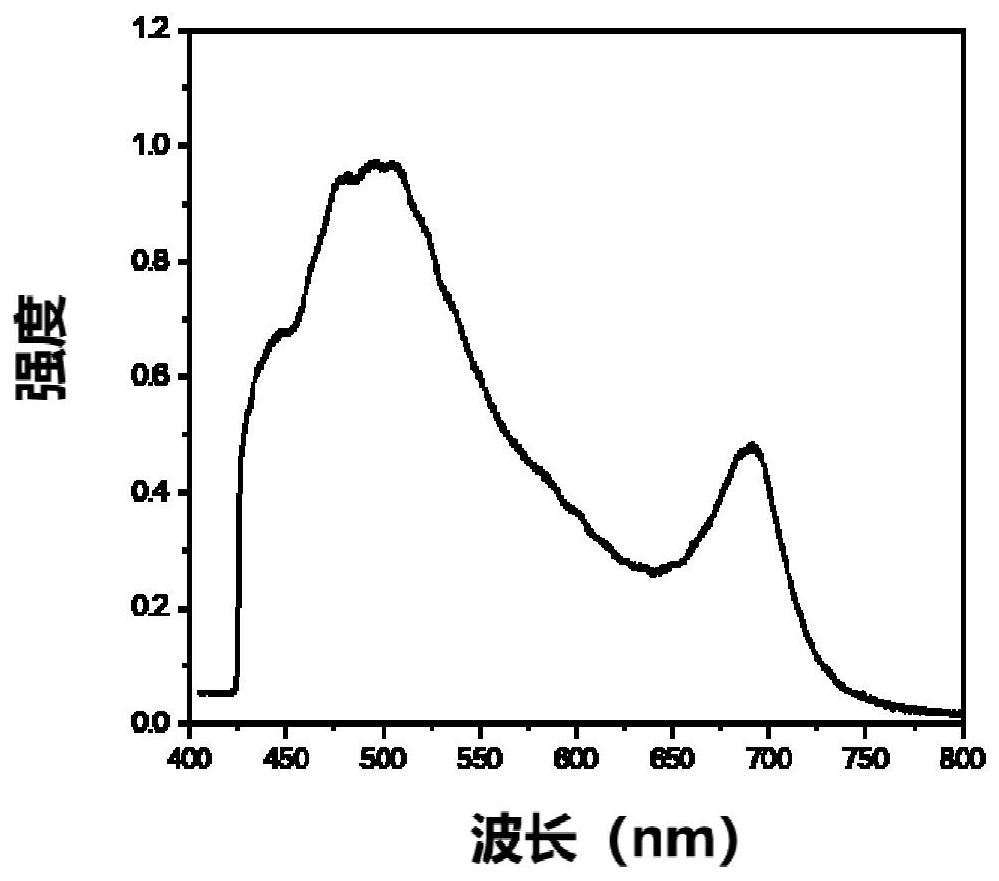

Image

Examples

Embodiment 1

[0030] A kind of controllable preparation CsPbI described in this embodiment 3 The method for the mixed-phase perovskite thin film specifically comprises the following steps:

[0031] 1) Add 15 mL of octadecene, 2 ml of oleylamine, 1 ml of oleic acid and 0.5 mmol of lead iodide into a three-necked flask, and place it in a heating mantle at 180°C, vacuumize the device and maintain an argon atmosphere to keep the temperature stable After 180° C., turn on the magnetic stirring at a stirring speed of 800 r / min.

[0032] 2) Cesium stearate and oleic acid were completely dissolved in octadecene at a molar ratio of 1:1.1 to form a precursor solution.

[0033] 3) Rapidly inject the prepared precursor mixture into the heating and stirring reaction solvent at a volume ratio of 1:15, react for 5-10 seconds, and quickly cool to room temperature with water.

[0034] 4) Wash the reaction product obtained above by adding a mixed solution of isopropanol and ethyl acetate, and centrifuge it,...

Embodiment 2

[0039] Similar to Example 1, the difference is that the mixed solution of Virahol and ethyl acetate in step 4 of Example 1 is changed to the mixed solution of Virahol and butyl acetate, and other conditions remain the same, and the CsPbI based 3 Materials for mixed-phase perovskite thin films.

Embodiment 3

[0041] Similar to Example 1, the difference is that the n-octane in step 4) of Example 1 is changed to n-hexane, and other conditions remain the same, and the CsPbI-based 3 Materials for mixed-phase perovskite thin films.

PUM

| Property | Measurement | Unit |

|---|---|---|

| external quantum efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com