Preparation method of rare earth upconversion nanoparticle/bismuth vanadate nano composite material with antitumor effect

A nanocomposite material, rare earth upconversion technology, applied in the field of synthesis of anti-tumor nanomaterials, can solve problems such as large size and limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

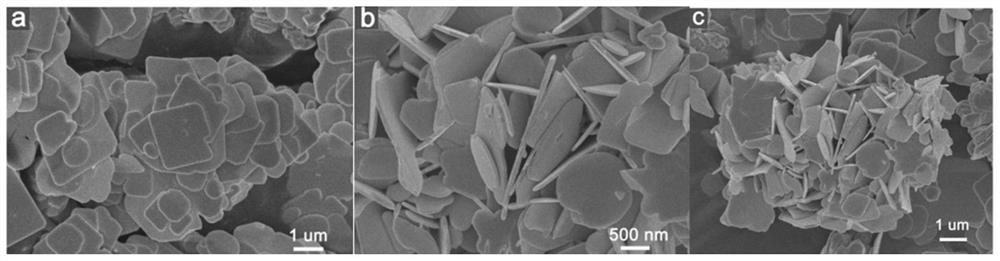

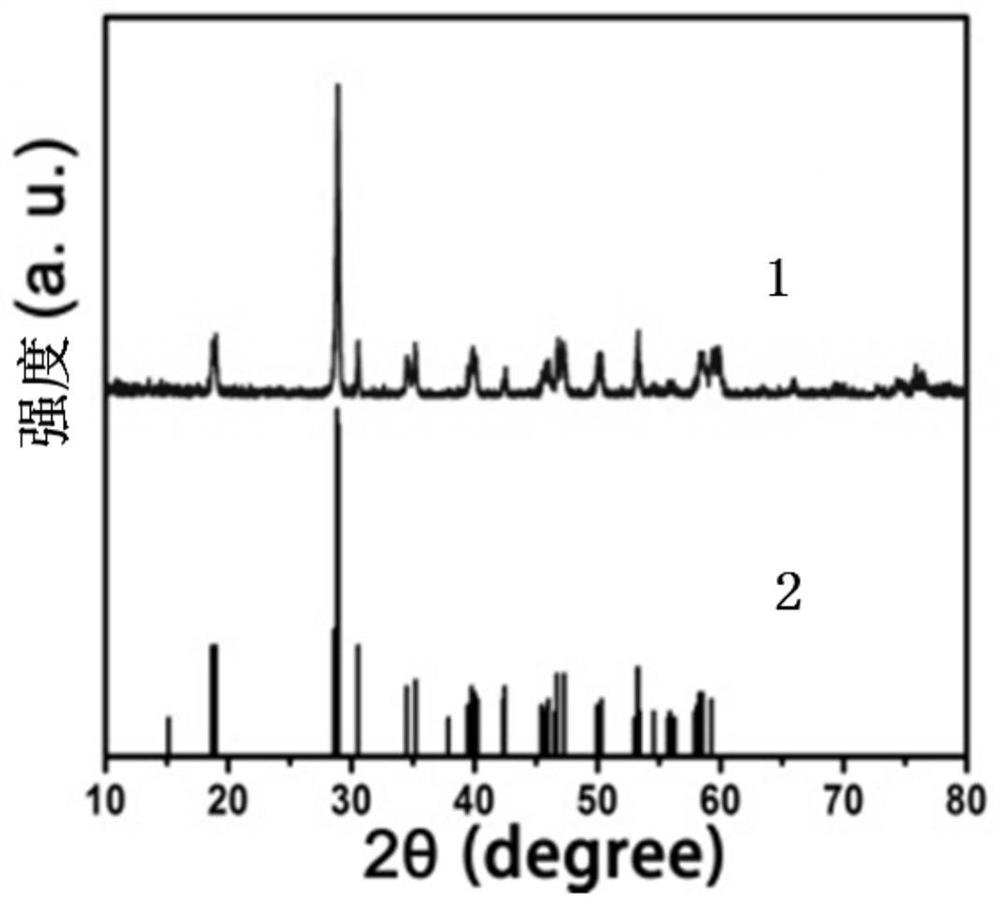

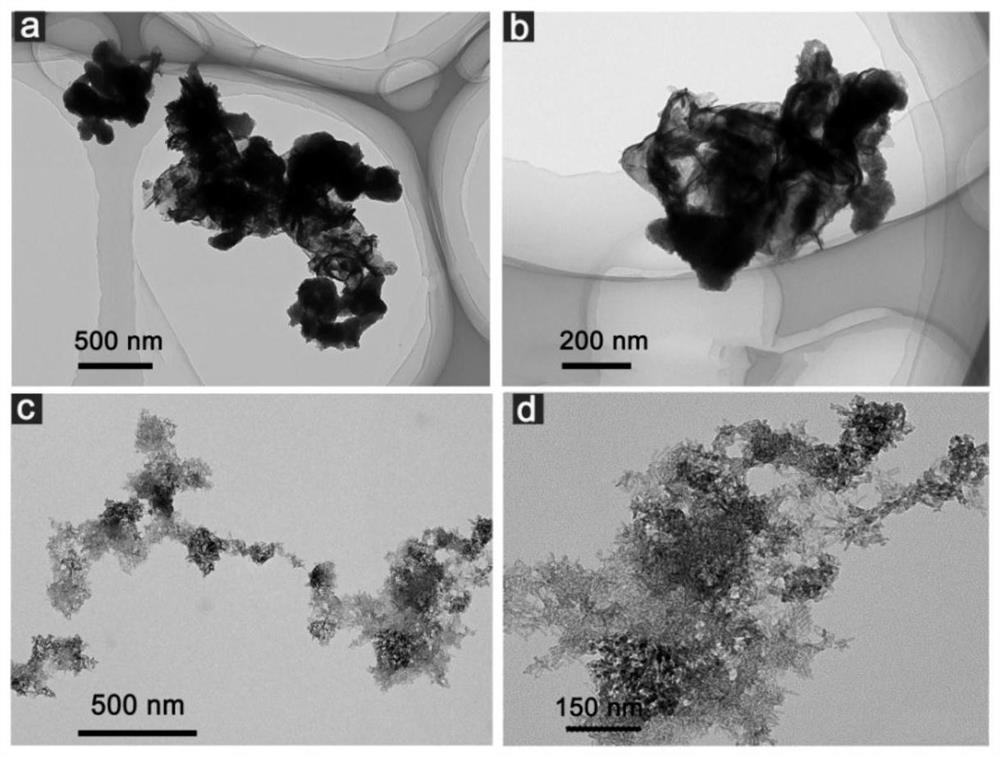

[0096] Specific embodiment one: present embodiment a kind of preparation method of rare earth up-conversion nanoparticles / bismuth vanadate nanocomposite material with anti-tumor effect, it is carried out according to the following steps:

[0097] 1. Preparation of synthetic core-structured nanoparticles:

[0098] ①. Add yttrium source, ytterbium source and thulium source into water respectively to obtain yttrium source aqueous solution, ytterbium source aqueous solution and thulium source aqueous solution respectively, and then mix the yttrium source aqueous solution, ytterbium source aqueous solution and thulium source aqueous solution to obtain yttrium source, ytterbium source aqueous solution and thulium source aqueous solution. A mixed solution of thulium source and thulium source;

[0099] The concentration of the yttrium source in the mixed solution of the yttrium source, the ytterbium source and the thulium source is 0.13g / mL~0.15g / mL; the concentration of the ytterbium...

specific Embodiment approach 2

[0160] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the yttrium source described in step one 1. is yttrium chloride; the ytterbium source described in step one 1. is ytterbium chloride; The thulium source described is thulium chloride; the inorganic fluoride described in step 1.3 is NH 4 F; The sodium source described in step 1.3. is NaOH. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0161] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the centrifugal washing described in step 14 is specifically under the condition that the centrifugal rate is 4000 rpm to 10000 rpm, first Centrifuge with ethanol to get the precipitate, then centrifuge with cyclohexane to get the supernatant, then centrifuge with ethanol to get the precipitate. Others are the same as in the first or second embodiment.

[0162] In this embodiment, the product is successively extracted with ethanol and cyclohexane and centrifuged to remove impurities to purify and separate the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com