Anticorrosive synthetic aviation lubricating oil and production method thereof

A technology for aviation lubricating oil and benzotriazole derivatives, which is applied in the field of lubricating oil to achieve the effects of good anti-oxidative stability, good product stability, and improved anti-corrosion and anti-rust performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

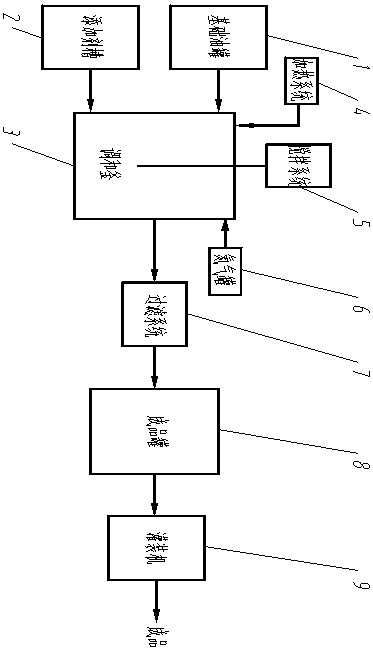

Method used

Image

Examples

Embodiment Construction

[0017] An anti-corrosion synthetic aviation lubricating oil, composed of 90-95% polyol ester, 2%-5% arylamine ester, 1%-4% phenyl phosphate, 0.01%-0.5% benzotriazole derivative, imidazoline derivative 0.01% to 0.5% of acrylate copolymer and 0.0005% to 0.0100% by weight of acrylate copolymer.

[0018] The polyol ester is a product of pentaerythritol ester reacted with saturated fatty acid as the ester base oil.

[0019] The arylamine ester is an amine antioxidant prepared by oxidative coupling reaction of aniline and naphthylamine compounds.

[0020] The phenyl phosphate is an extreme pressure antiwear agent.

[0021] The benzotriazole derivatives are chelated complexes formed by the benzotriazole derivatives as antirust agents.

[0022] The imidazoline derivatives are corrosion inhibitors synthesized by using C10-C18 saturated or unsaturated fatty acids and amine compounds as raw materials.

[0023] The acrylate copolymer is an antifoaming agent synthesized by dropwise addi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap