Graphene/TiN-Ag composite material and preparing method thereof

A composite material, graphene technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problem of strong dependence on excitation light source, and achieve excellent SERS performance, controllable thickness, and simple method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

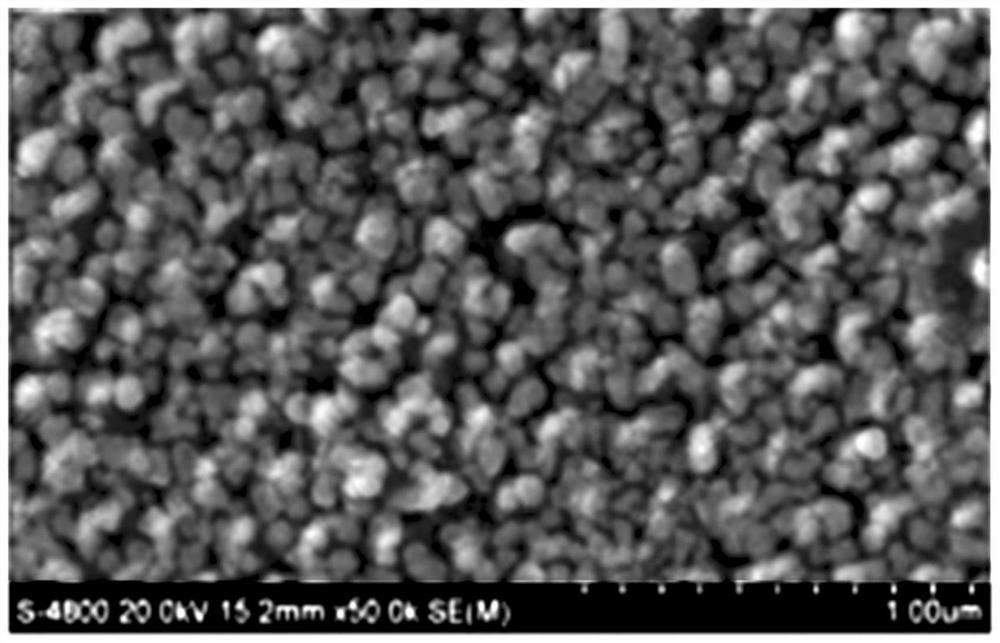

[0032] A graphene / TiN-Ag composite material, including a two-dimensional structure array template formed on a silicon wafer by the arrangement of polylactic acid microspheres, alternately deposited TiN-Ag layers and graphene layers on the template, TiN-Ag The deposited thicknesses of the layers and graphene layers were 50 nm and 2 nm, respectively.

[0033] Wherein, the molar ratio of TiN and Ag in the TiN-Ag layer is 10:1.

[0034] step one:

[0035] (1) Get the silicon wafer and soak it in 1% sodium lauryl sulfate solution for 12 hours to make it have hydrophilic properties;

[0036] (2) Prepare the ethanol solution of polylactic acid microspheres, according to the mass volume ratio of polylactic acid microspheres and ethanol solution, it is 1g:0.5mL after mixing and ultrasonically so that it is dispersed evenly;

[0037] (3) Drop the above-mentioned solution of polylactic acid ethanol on a hydrophilic silicon chip, spread the liquid evenly, insert it into the water obliqu...

Embodiment 2

[0042] A graphene / TiN-Ag composite material, including a two-dimensional structure array template formed on a silicon wafer by the arrangement of polylactic acid microspheres, alternately deposited TiN-Ag layers and graphene layers on the template, TiN-Ag The deposited thicknesses of the A layer and the graphene layer are 60 nm and 4 nm, respectively.

[0043] Wherein, the molar ratio of TiN and Ag in the TiN-Ag layer is 10:1.2.

[0044] step one:

[0045] (1) Get the silicon wafer and soak it in 2% sodium lauryl sulfate solution for 12 hours to make it have hydrophilic properties;

[0046] (2) prepare the ethanol solution of polylactic acid microspheres, according to the mass volume ratio of polylactic acid microspheres and ethanol solution is 1:0.5 after mixing ultrasonic, make it disperse evenly;

[0047](3) Drop the above-mentioned solution of polylactic acid ethanol on a hydrophilic silicon chip, spread the liquid evenly, insert it into the water obliquely, and spread t...

Embodiment 3

[0052] A graphene / TiN-Ag composite material, including a two-dimensional structure array template formed on a silicon wafer by the arrangement of polylactic acid microspheres, alternately deposited TiN-Ag layers and graphene layers on the template, TiN-Ag The deposited thicknesses of the A layer and the graphene layer are 70 nm and 8 nm, respectively.

[0053] Wherein, the molar ratio of TiN and Ag in the TiN-Ag layer is 10:1.7.

[0054] step one:

[0055] (1) Get the silicon chip and soak it in 3% sodium lauryl sulfate solution for 12 hours to make it have hydrophilic properties;

[0056] (2) prepare the ethanol solution of polylactic acid microspheres, according to the mass volume ratio of polylactic acid microspheres and ethanol solution is 1:0.5 after mixing ultrasonic, make it disperse evenly;

[0057] (3) Drop the above-mentioned solution of polylactic acid ethanol on a hydrophilic silicon chip, spread the liquid evenly, insert it into the water obliquely, and spread t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com