Passivator used for powder zincizing metal workpiece and preparing method and application of passivator

A technology for metal workpieces and powder zinc infiltration, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., can solve the problems of poor passivation effect, non-environmental protection and corrosion resistance of passivating agents, and achieve passivation Fast speed, good passivation effect, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

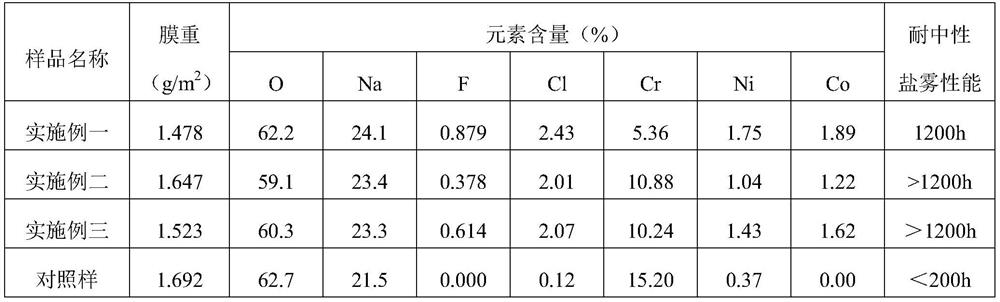

Examples

preparation example Construction

[0027] A preparation method of a passivating agent for powder sherardizing metal workpieces of the present invention comprises the following steps:

[0028] 1) taking water, heating the temperature of the water to 35-45 ° C, taking chromium trichloride, adding it to the water, stirring to obtain a chromium trichloride solution;

[0029] 2) get sodium nitrite, join it in the chromium trichloride solution of step 1) gained, stir, make it dissolve completely, obtain the first solution;

[0030] 3) get cobalt chloride and nickel chloride, join successively in the first solution of step 2) gained, stir, make it dissolve completely, obtain the second solution;

[0031] 4) take ammonium bifluoride, add it to the second solution obtained in step 3), stir to dissolve it completely, and obtain the third solution;

[0032] 5) get hydrogen peroxide, join in the third solution obtained in step 4), stir, make it dissolve completely, obtain the third solution;

[0033] 6) The third solutio...

Embodiment 1

[0041] A preparation method of a passivating agent for powder sherardizing metal workpieces of the present invention comprises the following steps:

[0042] 1) take by weighing raw materials according to the following parts by weight: chromium trichloride 5g, sodium nitrite 10g, nickel chloride 2g, cobalt chloride 5g, ammonium bifluoride 2g, mass concentration is 30% hydrogen peroxide 15mL, water 700mL;

[0043] 2) taking water, heating the temperature of the water to 35°C, taking chromium trichloride, adding it to the water, stirring to obtain a chromium trichloride solution;

[0044] 3) get sodium nitrite, join in the chromium trichloride solution of step 2) gained, stir, make it dissolve completely, obtain the first solution;

[0045] 4) get cobalt chloride and nickel chloride, join successively in the first solution of step 3) gained, stir, make it dissolve completely, obtain the second solution;

[0046] 5) take ammonium bifluoride, add it to the second solution obtained...

Embodiment 2

[0050] A preparation method of a passivating agent for powder sherardizing metal workpieces of the present invention comprises the following steps:

[0051] 1) take by weighing raw materials according to the following parts by weight: chromium trichloride 26g, sodium nitrite 20g, nickel chloride 4g, cobalt chloride 8g, ammonium bifluoride 6g, mass concentration is 30% hydrogen peroxide 25mL, water 700mL;

[0052] 2) taking water, heating the temperature of the water to 45°C, taking chromium trichloride, adding it to the water, stirring to obtain a chromium trichloride solution;

[0053] 3) get sodium nitrite, join in the chromium trichloride solution of step 2) gained, stir, make it dissolve completely, obtain the first solution;

[0054] 4) get cobalt chloride and nickel chloride, join successively in the first solution of step 3) gained, stir, make it dissolve completely, obtain the second solution;

[0055] 5) take ammonium bifluoride, add it to the second solution obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com