Preparation and application of positive electrode-interlayer integrated membrane electrode material for lithium-sulfur battery

A lithium-sulfur battery and membrane material technology, which is applied in the manufacture of battery electrodes, lithium batteries, and electrolyte batteries, can solve the problems of increasing operational difficulty, accelerating the growth of negative lithium dendrites, and shortening cycle life, so as to improve cycle stability , excellent electrochemical performance, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

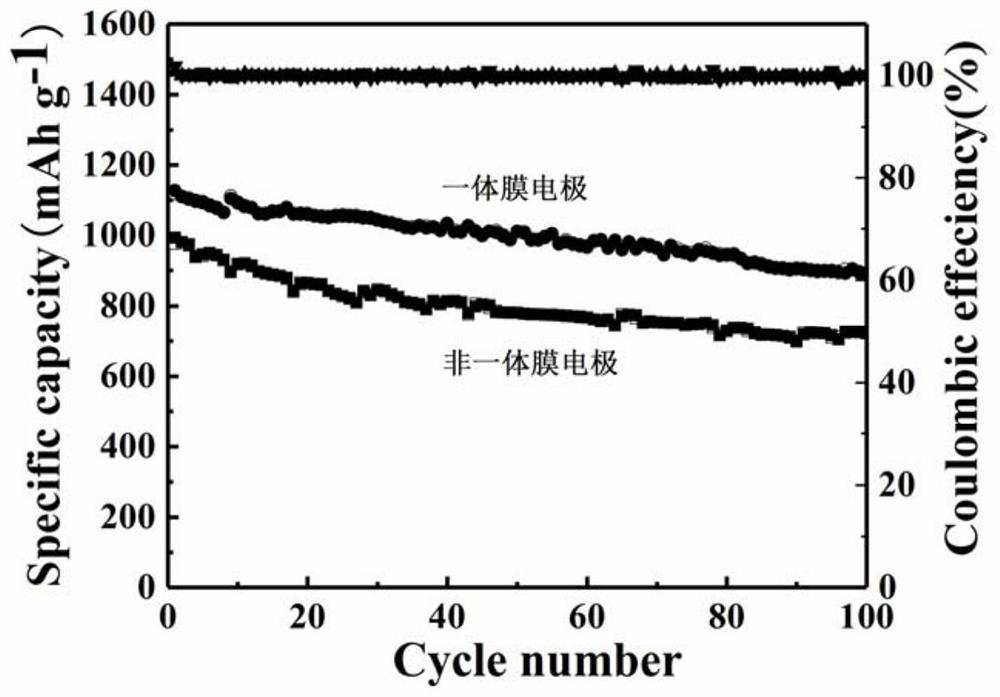

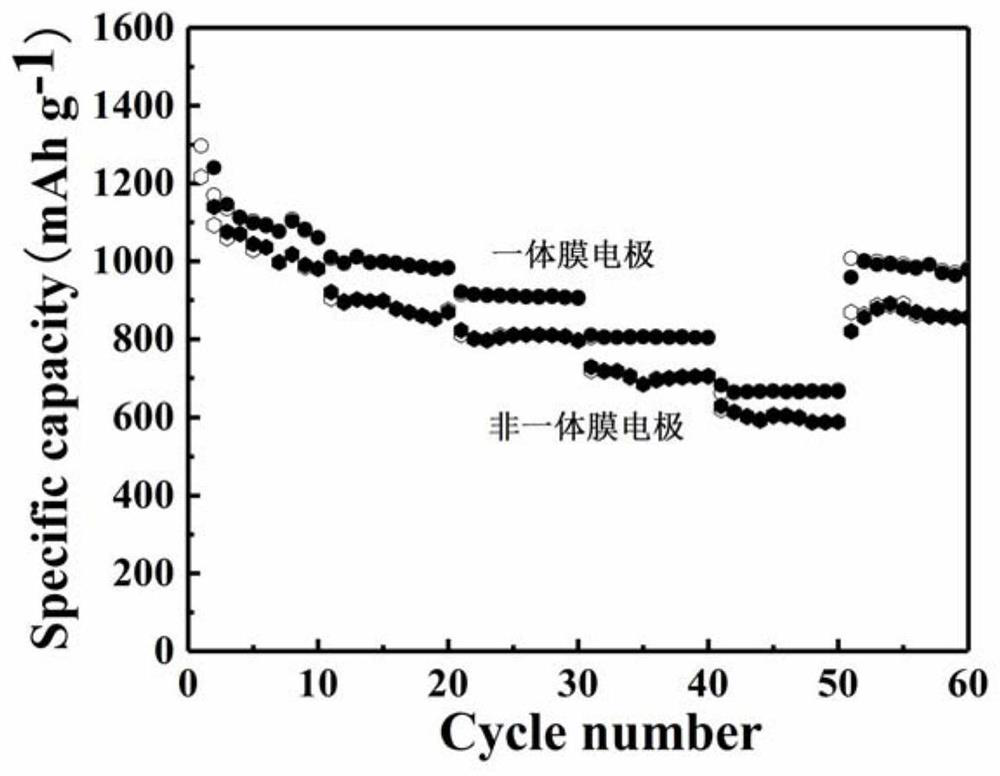

[0027] 1. Preparation of cathode-separator integrated membrane electrode materials for lithium-sulfur batteries

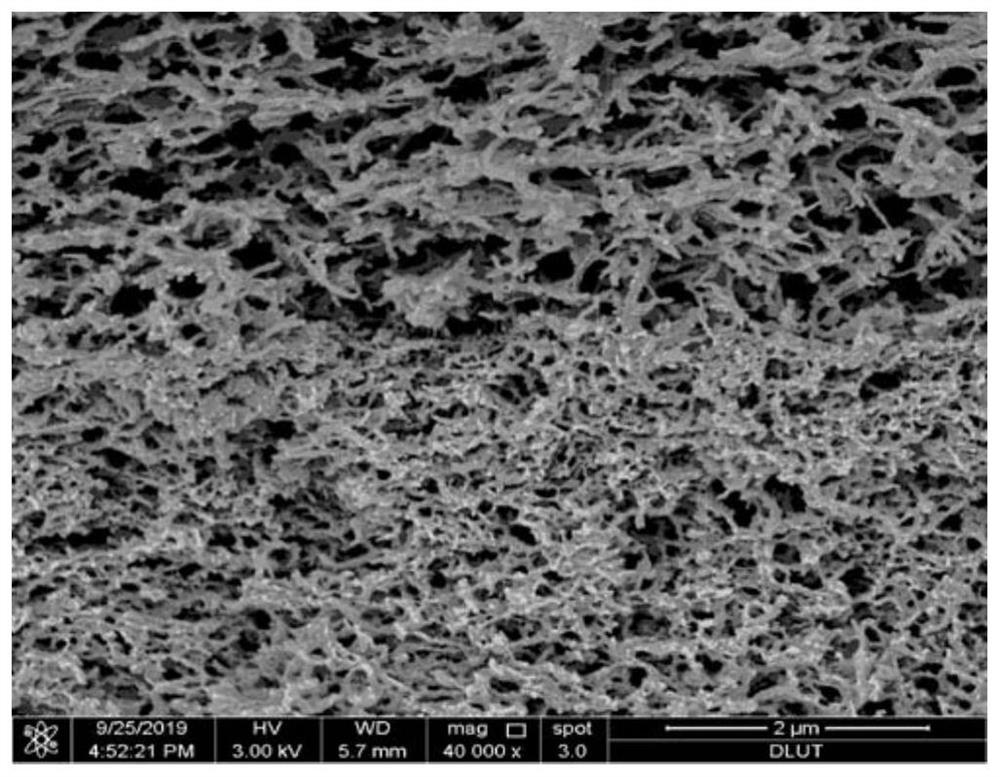

[0028] 1) Add 21g of N,N-dimethylformamide solvent and 1.5g of polyethylene glycol into a 100mL silk bottle to obtain solvent a, add 2.5g of carbon nanotubes to solvent a, stir to dissolve and add 2.5g Polyacrylonitrile, stir to dissolve, then magnetically stir the silk bottle at 80°C for 12 hours to form a uniform black casting solution, part of the casting solution is passed through an automatic film scraping machine to obtain a film layer with a thickness of 300 μm on a glass plate, and then Quickly put the glass plate covered with film into n-pentanol for 24h phase inversion;

[0029] 2) The phase-inverted film layer was taken out, dried on a glass plate, and then vacuum-dried at 90°C. The dried film layer was pre-oxidized in a muffle furnace at 2°C min -1 The heating rate was raised to 250°C, and the temperature was kept constant for 2 hours. Finally, the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com