Zinc-doped mixed transition metal sulfide electrode material and preparation method thereof

A technology of transition metals and electrode materials, applied in the direction of active material electrodes, positive electrodes, battery electrodes, etc., can solve the problems of nickel-cobalt sulfide cycle and rate performance that need to be further improved, so as to improve electrochemical performance, promote full penetration, Operational controllable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

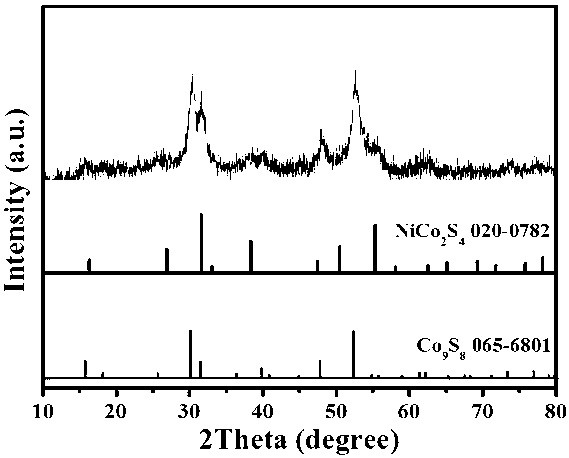

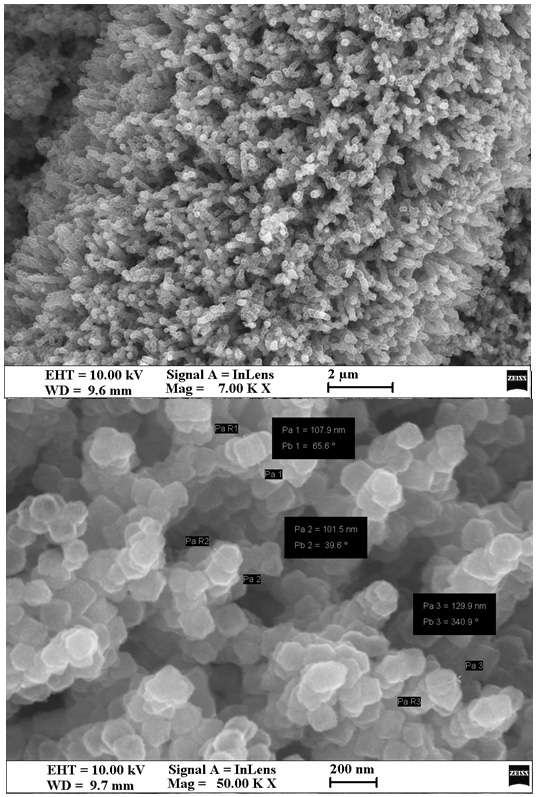

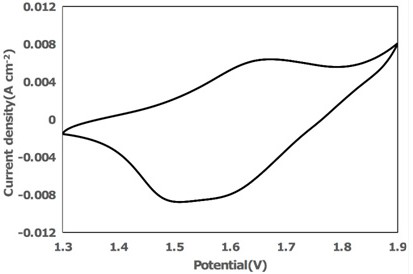

[0026] A method for preparing a zinc-doped mixed-type transition metal sulfide electrode material, the specific steps are:

[0027] (1) Sonicate the carbon cloth with deionized water for about 30 minutes. Weigh 0.5 g of cobalt nitrate hexahydrate, 0.5 g of nickel nitrate hexahydrate, and 0.2 g of urea into 30 ml of deionized water, ultrasonically dissolve them and put them in a hydrothermal kettle. Heat reaction for 3 hours. After natural cooling, take out the carbon cloth and rinse and dry it several times;

[0028] (2) Weigh 0.3 g of cobalt nitrate hexahydrate and 0.08 g of zinc nitrate hexahydrate, add to 30 ml of methanol to obtain solution A, weigh 0.7 g of dimethylimidazole and add to 30 ml of methanol to obtain solution B, ultrasonically dissolve respectively, Immerse the product of step (1) in solution A, and stir slowly on a magnetic stirrer for 30 minutes, then slowly and uniformly drop solution B into solution A with a straw for 10 minutes, and continue stirring f...

Embodiment 2

[0032] A method for preparing a zinc-doped mixed-type transition metal sulfide electrode material, the specific steps are:

[0033] (1) Sonicate the carbon cloth with deionized water for about 60 minutes. Weigh 1.5 g of cobalt nitrate hexahydrate, 0.8 g of nickel nitrate hexahydrate and 0.5 g of urea into 70 ml of deionized water, ultrasonically dissolve them and put them in a hydrothermal kettle. Thermal reaction for 6 hours. After natural cooling, take out the carbon cloth and rinse and dry it several times;

[0034] (2) Weigh 0.5 g of cobalt nitrate hexahydrate and 0.15 g of zinc nitrate hexahydrate, add to 50 ml of methanol to obtain solution A, weigh 1.2 g of dimethylimidazole and add to 50 ml of methanol to obtain solution B, ultrasonically dissolve respectively, Immerse the product of step (1) in solution A, and stir slowly on a magnetic stirrer for 30 minutes, then slowly and uniformly drop solution B into solution A with a straw for 10 minutes, and continue stirring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com