Aqueous zinc ion battery electrolyte and application thereof

A zinc-ion battery and electrolyte technology, applied in water-based electrolytes, secondary batteries, composite electrolytes, etc., can solve the problems of low coulombic efficiency, low coulombic efficiency of negative electrodes, and performance degradation of zinc negative electrodes, so as to improve the electrochemical window and reduce the Electrochemical activity, the effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

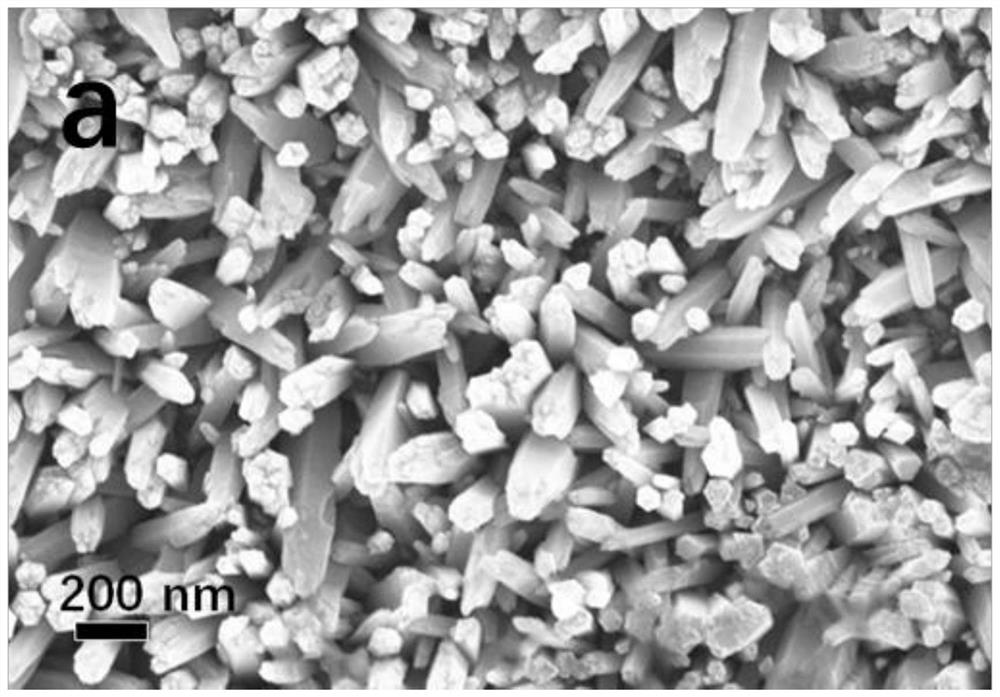

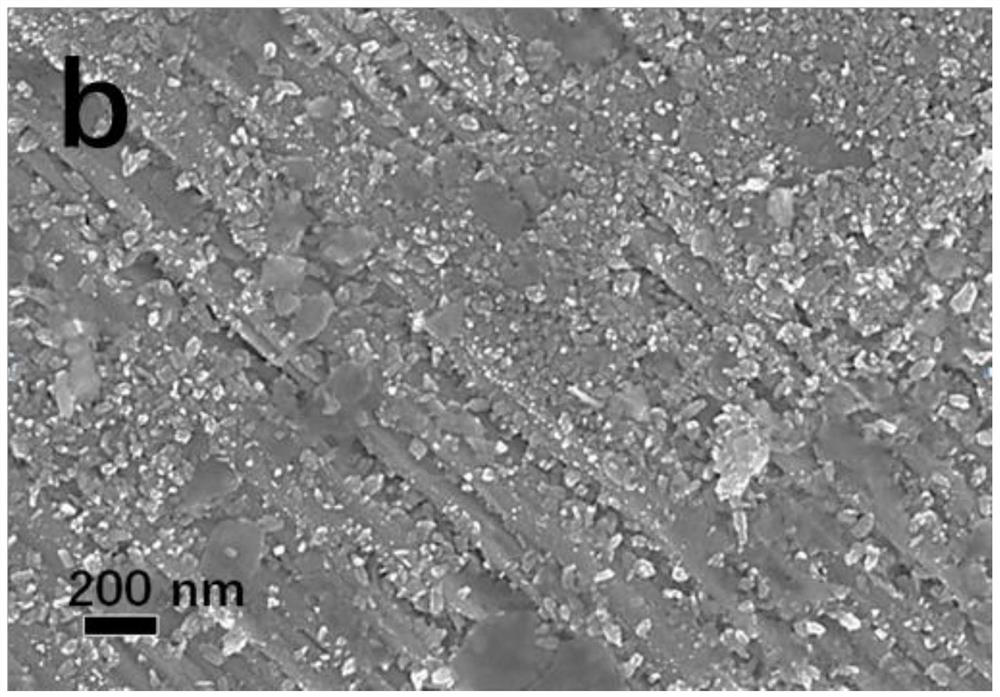

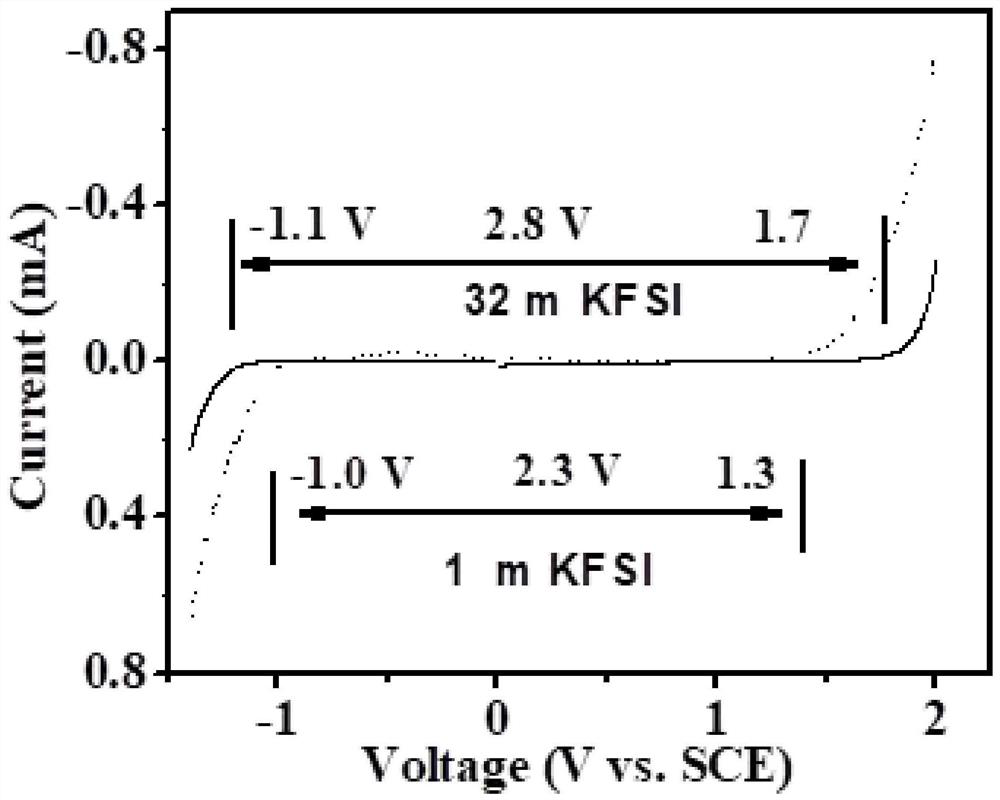

[0030] The electrolyte solution of the water-based zinc-ion battery in this example is specifically composed of solvent water, high-concentration potassium bisfluorosulfonimide (KFSI) and zinc salt, wherein the zinc salt is zinc trifluoromethanesulfonate. Its preparation method is as follows: weigh KFSI according to the mass molar concentration of 32mol / kg, weigh zinc trifluoromethanesulfonate according to the mass molar concentration of 1mol / kg, and dissolve the two in water to obtain the high-concentration KFSI of this example. Aqueous zinc-ion battery electrolyte.

[0031]In addition, as a comparison, prepare a water-based zinc ion electrolyte with a low concentration of potassium bisfluorosulfonimide, specifically, according to the mass molar concentration of KFSI is 1mol / kg, and the mass molar concentration of zinc trifluoromethanesulfonate is 1mol / kg Each component was weighed and dissolved in water to obtain the aqueous zinc-ion battery electrolyte for the comparative t...

Embodiment 2

[0040] The specific composition of the aqueous zinc ion battery electrolyte of this example is water, high-concentration potassium trifluoromethanesulfonate and zinc salt zinc chloride, and is added with functional additive sulfonamide, and its preparation method is as follows: according to the formula of potassium trifluoromethanesulfonate The mass molar concentration is 20mol / kg, the mass molar concentration of zinc chloride is 2mol / kg, and the sulfonamide accounts for 1.5% of the total weight of the electrolyte. Weigh each component and dissolve it in water to obtain the aqueous zinc ion of this example battery electrolyte.

[0041] The same method as in Example 1 was used to observe the growth of dendrites on the surface of the zinc sheet using the electrolyte solution of the aqueous zinc-ion battery of this example. The results show that the surface of the zinc flakes using the high-concentration potassium trifluoromethanesulfonate aqueous zinc ion electrolyte of this exa...

Embodiment 3

[0046] The specific composition of the aqueous zinc-ion battery electrolyte in this example is water, high-concentration potassium bisfluorosulfonimide and zinc salt zinc perchlorate, and polyethylene glycol with a molecular weight of 300 is added as a functional additive. The preparation method is as follows: The mass molar concentration of bisfluorosulfonimide potassium is 20mol / kg, the mass molar concentration of zinc perchlorate is 2mol / kg, and polyethylene glycol accounts for 1% of the total weight ratio of the electrolyte. Weigh each component, dissolve In water, the aqueous zinc-ion battery electrolyte of this example is obtained.

[0047] The same method as in Example 1 was used to observe the growth of dendrites on the surface of the zinc sheet using the electrolyte solution of the aqueous zinc-ion battery of this example. The results show that using the aqueous zinc ion electrolyte with high concentration of potassium bisfluorosulfonimide in this example, 0.2mA / cm 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com