Efficient preparation method and application of protein polysaccharide compound

A protein and complex technology, which is applied in the field of efficient preparation of protein polysaccharide complexes, can solve the problems of poor protein thermal stability and acid resistance, low protein content, and long process time, so as to shorten the preparation time and cost, and accelerate the dispersion speed , the effect of reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

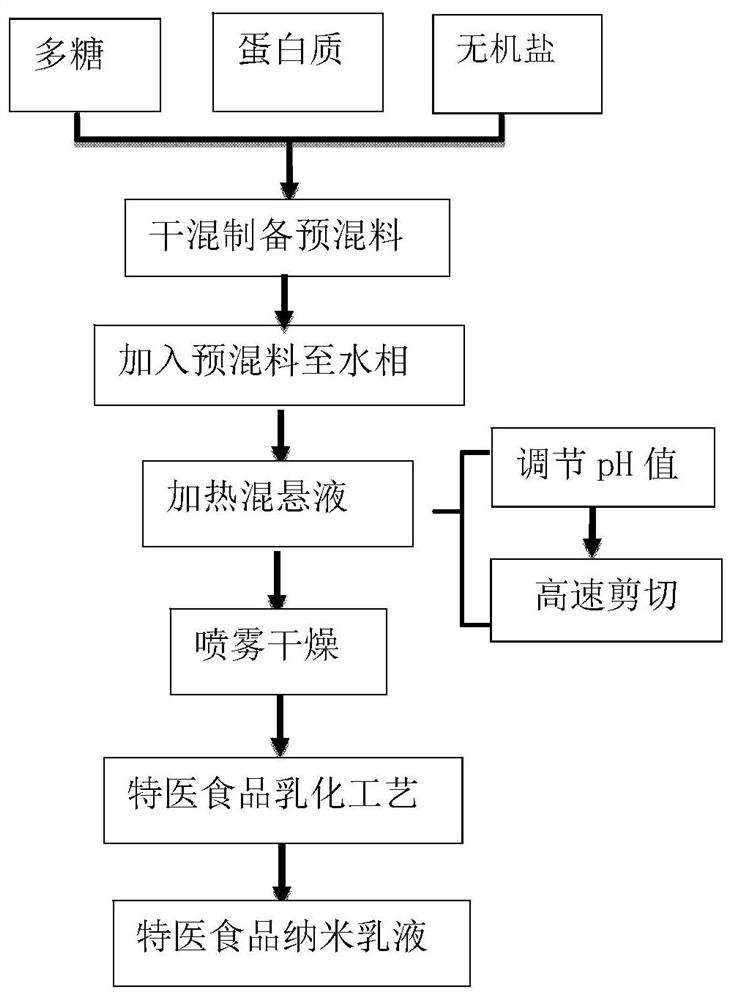

[0042] Such as figure 1 As shown, the special medical food nanoemulsion is prepared by the following steps:

[0043] 1. Weigh 3kg of maltodextrin, 1kg of sodium caseinate, 0.5kg of whey protein, and 3.5g of zinc chloride, and dry mix them with a mechanical mixer for 60s;

[0044] 2. Add dry-blended maltodextrin, protein, and zinc chloride to 10.5kg of water and stir; at the same time, add 0.1M sodium hydroxide to adjust the pH of the suspension to pH 8, stir and heat to 90°C for 30 minutes;

[0045] 3. In step 2, after adjusting the pH, perform high-speed shearing at 2800 rpm for 15 minutes until the suspension has no visible particles. The total time for dispersing the suspension is 45 minutes;

[0046] 4. The suspension is spray-dried, the air inlet temperature is 170°C, and the outlet air temperature is 90°C;

[0047] 5. Use special medical food emulsion preparation technology for nanoemulsion preparation, including adding oil, minerals, vitamins, shearing, homogenizing,...

Embodiment 2

[0049] Such as figure 1 As shown, the special medical food nanoemulsion is prepared by the following steps:

[0050] 1. Weigh 0.42kg of resistant dextrin, 2kg of casein, 0.1kg of hydrolyzed whey protein, and 2.52g of sodium chloride, and dry-mix for 60s with a mechanical mixer;

[0051] 2. Add the dry mixed resistant dextrin, protein, and sodium chloride into 3.78kg of water and stir; at the same time, add 0.1M sodium hydroxide to adjust the pH of the suspension to pH 7, stir and heat for 30 minutes to 60°C ;

[0052] 3. In step 2, after adjusting the pH, perform high-speed shearing at 1000 rpm for 20 minutes until the suspension has no visible particles. The total time for dispersing the suspension is 45 minutes;

[0053] 4. The suspension is spray-dried, the inlet air temperature is 180°C, and the outlet air temperature is 100°C;

[0054] 5. Use special medical food emulsion preparation technology for nanoemulsion preparation, including adding oil, minerals, vitamins, sh...

Embodiment 3

[0056] Such as figure 1 As shown, the special medical food nanoemulsion is prepared by the following steps:

[0057] 1. Weigh 2kg of pectin, 1kg of soybean polypeptide, 1kg of pea protein, and 3.3g of sodium citrate, and dry mix them with a mechanical mixer for 60s;

[0058] 2. Add the dry-blended pectin, protein, and sodium citrate into 16kg of water and stir; at the same time, add 0.1M sodium hydroxide to adjust the pH of the suspension to pH8, stir and heat to 60°C for 30 minutes;

[0059] 3. In step 2, after adjusting the pH, perform high-speed shearing at 2000rpm for 15 minutes until the suspension has no visible particles. The total time for dispersing the suspension is 45 minutes;

[0060] 4. The suspension is spray-dried, the air inlet temperature is 180°C, and the outlet air temperature is 90°C;

[0061] 5. Use special medical food emulsion preparation technology for nanoemulsion preparation, including adding oil, minerals, vitamins, shearing, homogenizing, and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com