Microneedle patch and preparation method thereof

A micro-needle sticker and micro-needle technology, applied in the fields of biomedicine and medical cosmetology, can solve the problems of rapid degradation and painful insertion into the skin, and achieve the effect of improving degradation performance and facilitating the hardness of micro-needles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Example 1: Comparison of microneedle degradation performance

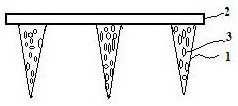

[0065] In this experiment, the degradation performance and hardness of the microneedles were compared. The pH of the microneedles was 7.2. The diameter of the microneedles containing cross-linked sodium hyaluronate was 300 μm, the height was 0.25 mm, the distance between the microneedles was 0.3 mm, and the diameter of the needle tip was 10 μm. The cross-linking degree of sodium hyaluronate is 2%, the residual cross-linking agent is 1 ppm, and the performance parameters related to the microneedles are shown in Table 1.

[0066] Degradation performance is expressed as residual percentage (%): 300 mg of microneedles are put into a 1 ml centrifuge tube, 1 ml of water for injection is added, and after thorough mixing, hyaluronidase is added to each tube at a concentration of 30 IU / ml. The sample without enzyme addition and other operations kept the same as the control. 37 ℃ constant temperature for half an hour...

Embodiment 2

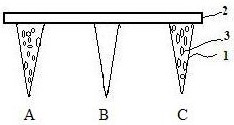

[0070] Example 2: Comparison of microneedle degradation performance

[0071]In this experiment, the degradation performance and hardness of the microneedles were compared. The pH of the microneedles was 7.5, the diameter of the microneedles containing cross-linked collagen was 500 μm, the height was 0.2 mm, the distance between the microneedles was 0.5 mm, the diameter of the needle tip was 10 μm, and the cross-linking agent remained. is 2ppm, and the performance parameters related to the microneedle are shown in Table 2.

[0072] Degradation performance was expressed as residual percentage (%): 300 mg of microneedles were put into a 1 ml centrifuge tube, 1 ml of water for injection was added, and after thorough mixing, collagenase was added to each tube at a concentration of 20 IU / ml. The sample without enzyme addition and other operations kept the same as the control. 37 ℃ constant temperature for half an hour. After the reaction, each tube was centrifuged, the supernatant...

Embodiment 3

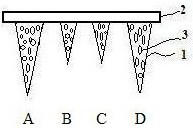

[0076] Example 3: Performance comparison of microneedles

[0077] In this experiment, the applicant further comparatively studied the hardness and experience of the microneedles in Example 1 and Example 2, and the result parameters are shown in Table 3.

[0078] Hardness test method: insert the needle tip of the microneedle into a rubber with a thickness of 2.5 mm, and the insertion speed is 6 mm / s, and measure the maximum force when inserting the rubber, which is the hardness of the microneedle. The greater the insertion force, the higher the hardness.

[0079] Experience test method: subjective judgment when inserting into the skin, 0 points for no pain, 1 point for general pain, 2 points for pain, 3 points for very pain, and 4 points for unacceptable pain.

[0080] table 3.

[0081] Numbering Hardness (N) experience score 1-1 0.312 1 1-2 0.328 1 1-3 0.354 1 1-4 0.373 1 1-5 0.394 1 1-6 0.395 1 1-7 0.493 2 2-1 0.3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com