Gel casting method of zirconia ceramic

A technology of gel injection molding and zirconia ceramics, which is applied in the field of ceramic material molding, can solve the problems that air bubbles cannot be completely eliminated, affect the preparation of high-density products, and cannot solve the problems of oxygen inhibition, etc., and achieve high cost performance, increase density, increase The effect of connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A gel injection molding method of zirconia ceramics, comprising the following steps:

[0034] Step 1. Add 10g of B ester to the reaction device with a condensing reflux device and a stirrer, heat it to (50±2)°C while stirring, and then keep it warm; slowly add 50g of acrylamide to the B ester, wait After the acrylamide is completely dissolved, add 0.25g p-methoxyphenol and stir evenly;

[0035] Step 2, using ammonia water to adjust the pH value of the solution to 9.5;

[0036] Step 3, slowly add 65g of paraformaldehyde to the solution, and add triethylamine to control the pH value of the solution to 9.5, and continue to stir for 120 minutes;

[0037] Step 4, filter the solution, and cool the filtrate to below 25°C;

[0038] Step 5, using centrifugation to separate the crystals precipitated in the filtrate after cooling;

[0039] Step 6: Take 40 g of crystals obtained by centrifugation, 300 g of deionized water, 10 g of ammonium polyacrylate as a dispers...

Embodiment 2

[0049] Embodiment 2: A gel injection molding method of zirconia ceramics, comprising the following steps:

[0050] Step one to step five are the same as embodiment 1;

[0051] Step 6. Take 30g of crystals obtained by centrifugation, 280g of deionized water, 0.15g of N,N-methylenebisacrylamide, 20g of ammonium polyacrylate as a dispersant, 1g of n-octanol and 1g of acetylene glycol as a defoaming agent, mix and stir Uniform, prepared into a premix;

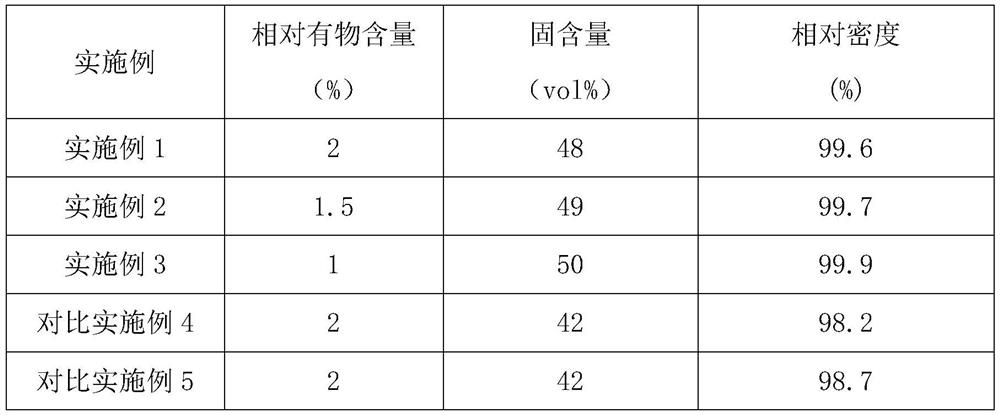

[0052] Step 7. Add the premixed liquid into the ball mill tank, and gradually add 2000 g of nano-zirconia powder with a D50 of 0.4um. After the powder is added, ball mill until there is no powder agglomerated particles in the slurry, and the relative content of organic matter is 1.5%. A slurry with a solid phase volume content of 49%; the viscosity of the slurry is 287mpa s, which meets the requirements of the gel injection molding process;

[0053] Step 8. Transfer the ball-milled slurry to a vacuum tank, and stir and degas for ...

Embodiment 3

[0059] Embodiment 3: a kind of gel injection molding method of zirconia ceramics, comprising the following steps:

[0060] Step one to step five are the same as embodiment 1;

[0061] Step 6: Take 20g of crystals obtained by centrifugation, mix with 260g of deionized water, 0.2g of N,N-methylenebisacrylamide, 30g of ammonium polyacrylate as a dispersant, and 1g each of n-octanol and acetylenic diol as a defoaming agent and mix them. Stir evenly to make a premix;

[0062] Step 7. Add the premixed solution into the ball mill tank, and gradually add 2000 g of nano-zirconia powder with a D50 of 0.5um. After the powder is added, ball mill until there is no powder agglomerated particles in the slurry, and the relative content of organic matter is 1%. A slurry with a solid phase volume content of 50%; the viscosity of the slurry is 430mpa s, which meets the requirements of the gel injection molding process;

[0063] Step 8. Transfer the ball-milled slurry to a vacuum tank, and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com