Preparation method of chiral aminochloroquinoline

A technology of aminochloroquinoline and dichloroquinoline, applied in the field of medicine, can solve problems such as few chloroquine synthesis methods, and achieve the effect of high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

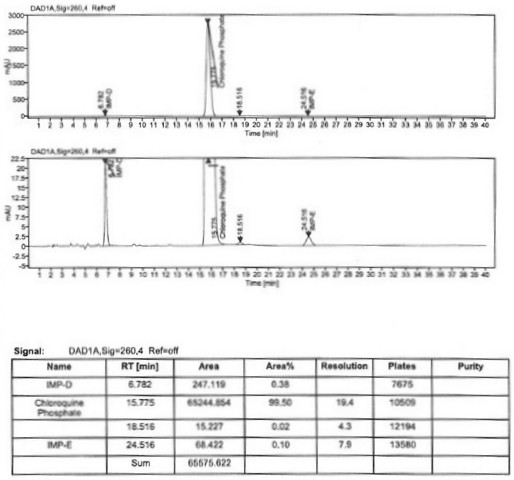

Embodiment 1

[0032] The reaction formula is as follows:

[0033] 1. Resolution of 2-amino-5-diethylaminopentane:

[0034]

[0035] 2. Enantiomer synthesis:

[0036]

[0037] 1. Resolution of 2-amino-5-diethylaminopentane:

[0038] a. 80g of 2-amino-5-diethylaminopentane, 0.51mol, add 40ml of isopropanol, heat to dissolve, add 41g of D-mandelic acid, 0.27mol, stir for 6 hours, filter with suction, keep the filtrate for use, and collect off-white solid . Vacuum drying at 60-65°C yielded 67g of L-mandelic acid salt;

[0039] b. Add 41 g of L-mandelic acid (0.27 mol) to the filtrate of the previous step, stir at room temperature for 10 hours, filter, and collect an off-white solid. Vacuum drying at 60-65°C yielded 62 g of D-mandelic acid salt.

[0040] 2. Preparation of enantiomeric salts:

[0041] a. 67g of the L-mandelate prepared in the above 1(a), add 150g of purified water, add 20% sodium hydroxide to neutralize to PH = 11, add 500g of dichloromethane, stir for 30min, separate...

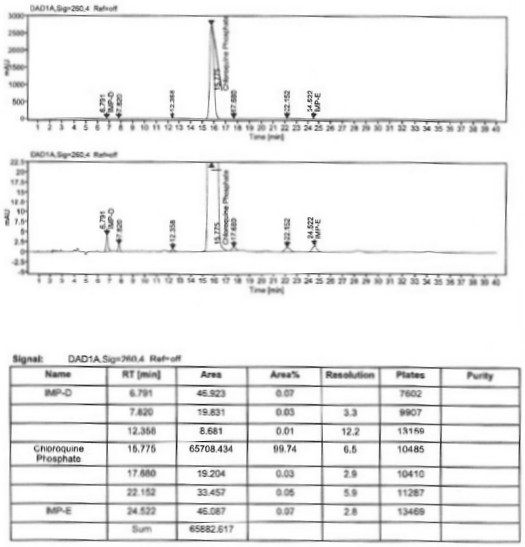

Embodiment 2

[0045] 1. Resolution of 2-amino-5-diethylaminopentane:

[0046]a. 80g of 2-amino-5-diethylaminopentane, 0.51mol, add 45ml of isopropanol, heat to dissolve, add 43g of D-mandelic acid, 0.28mol, stir for 7 hours, filter with suction, keep the filtrate for use, and collect off-white solid . Vacuum drying at 60-65°C yielded 68.3 g of L-mandelic acid salt;

[0047] b. Add 43g of L-mandelic acid (0.28mol) to the filtrate of the previous step, stir at room temperature for 10 hours, filter, and collect an off-white solid. Vacuum drying at 60-65°C yielded 63.4 g of D-mandelic acid salt;

[0048] 2. Preparation of enantiomeric salts:

[0049] a. Add 68.3g of L-mandelate prepared in the above 1(a), add 155g of purified water, add 25% sodium hydroxide to neutralize to PH=11, add 550g of dichloromethane, stir for 30min, separate layers, concentrate under reduced pressure for two Chloromethane, to get the side chain left-handed free base.

[0050] b. Add 43.6 g (0.22 mol) of 4,7-dichlo...

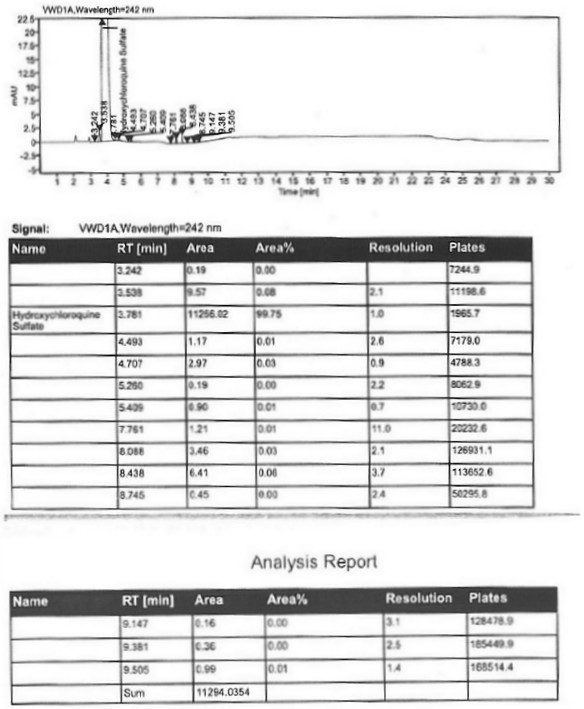

Embodiment 3

[0053] 1. Resolution of 2-amino-5-diethylaminopentane:

[0054] a. 80g 2-amino-5-diethylaminopentane 0.51mol), add 40ml isopropanol, heat to dissolve, add 60g D-camphorsulfonic acid, 0.27mol, stir for 6 hours, filter with suction, keep the filtrate for use, collect off-white solid. Vacuum drying at 60-65°C to obtain 85g of levocamphorsulfonate;

[0055] b. Add 60 g of L-camphorsulfonic acid (0.26 mol) to the filtrate of the previous step, stir at room temperature for 10 hours, filter, and collect an off-white solid. Vacuum drying at 60-65°C to obtain 80g of D-camphorsulfonate;

[0056] 2. Preparation of enantiomeric salts:

[0057] a. Add 85 g of the levocamphorsulfonate prepared in the above 1 (a), add 180 g of purified water, add 20% sodium hydroxide to neutralize to PH=11, add 500 g of dichloromethane, stir for 30 min, separate layers, and concentrate under reduced pressure. Chloromethane, to get the side chain left-handed free base.

[0058] b. Add 42 g (0.21 mol) of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com